Разделы презентаций

- Разное

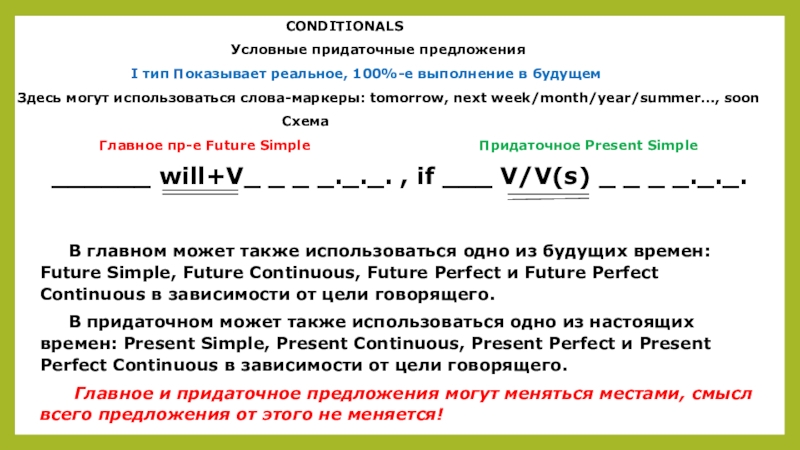

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

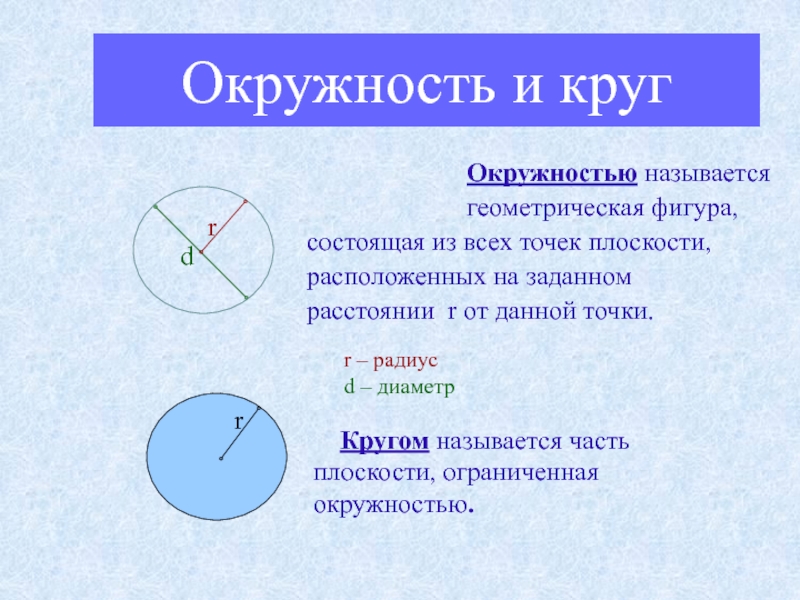

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

1 Bioenergy - biofuels Magnús Guðmundsson Innovation Center of Iceland Magnús

Содержание

- 1. 1 Bioenergy - biofuels Magnús Guðmundsson Innovation Center of Iceland Magnús

- 2. Слайд 2

- 3. Bio-fuels- definitions Bio-fuels are made from sustainable

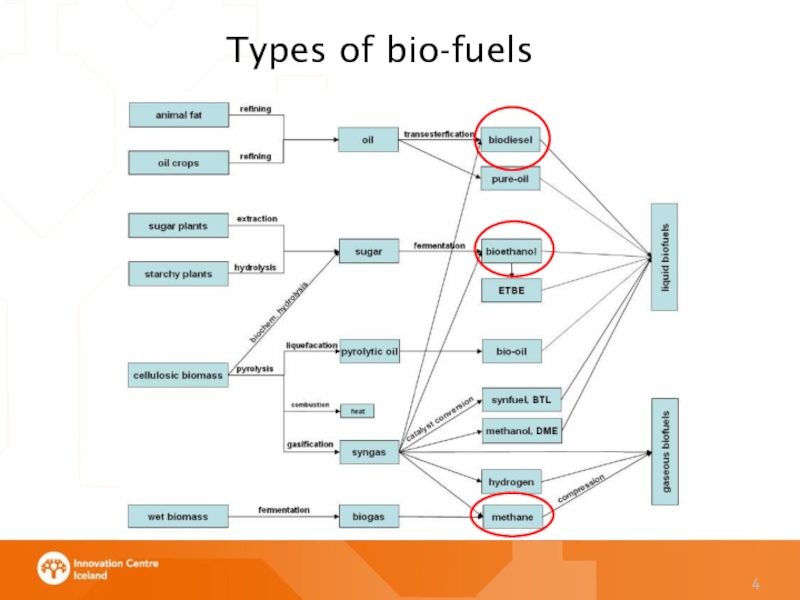

- 4. Types of bio-fuels

- 5. Ethanol fermentationYeasts are mostly used today to

- 6. 1°- and 2° generation productionLigno-cellulose plantsTreesAgricultural wasteGrass/helmStarchy

- 7. First and second generation ethanol(from Toefl TU

- 8. Bio-Ethanol Henry Ford started to use pure

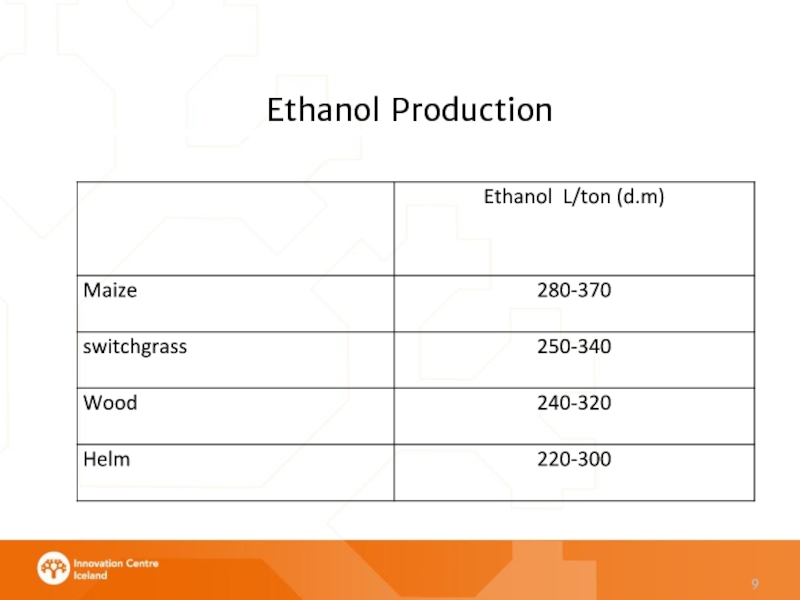

- 9. Ethanol Production

- 10. Food versus fuels

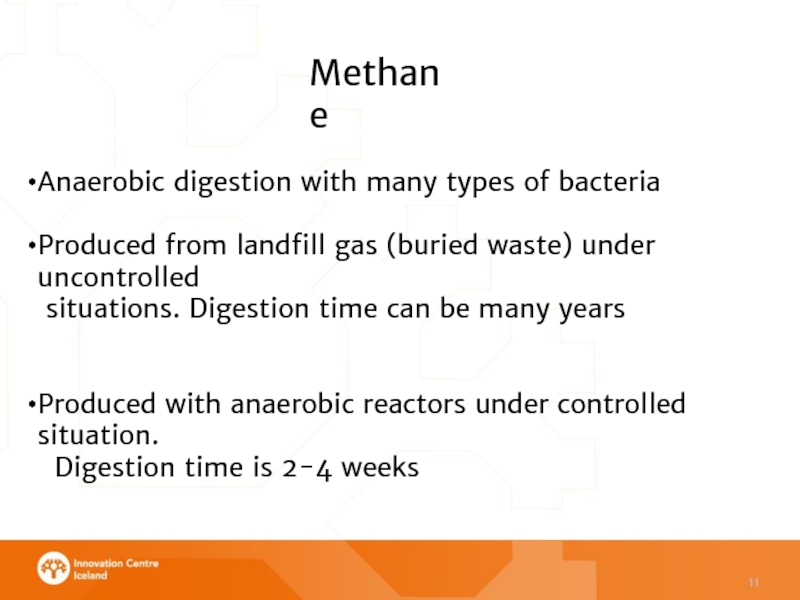

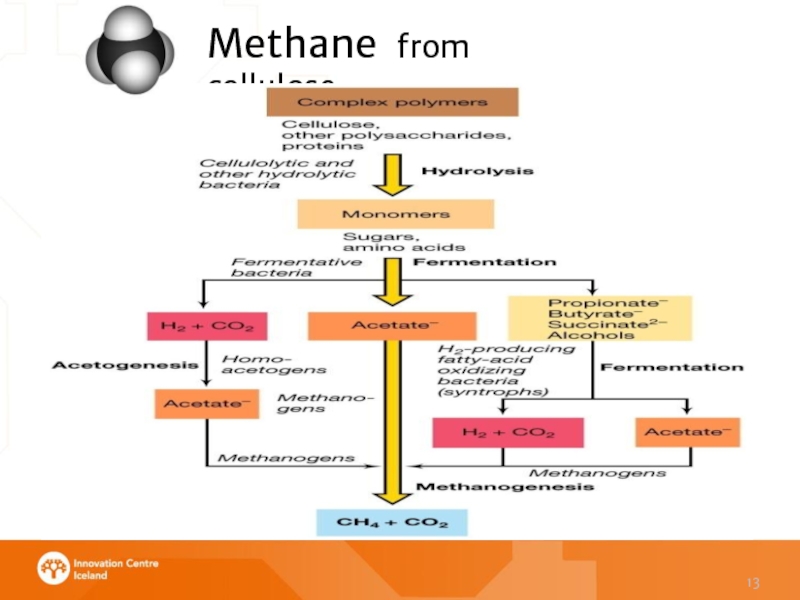

- 11. MethaneAnaerobic digestion with many types of bacteriaProduced

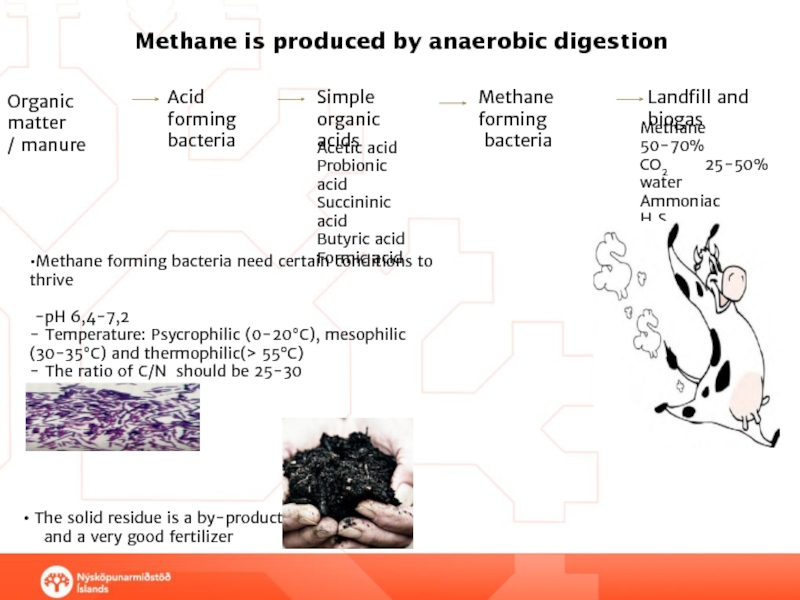

- 12. Methane is produced by anaerobic digestion

- 13. Thank you for your attentionMethane from cellulose

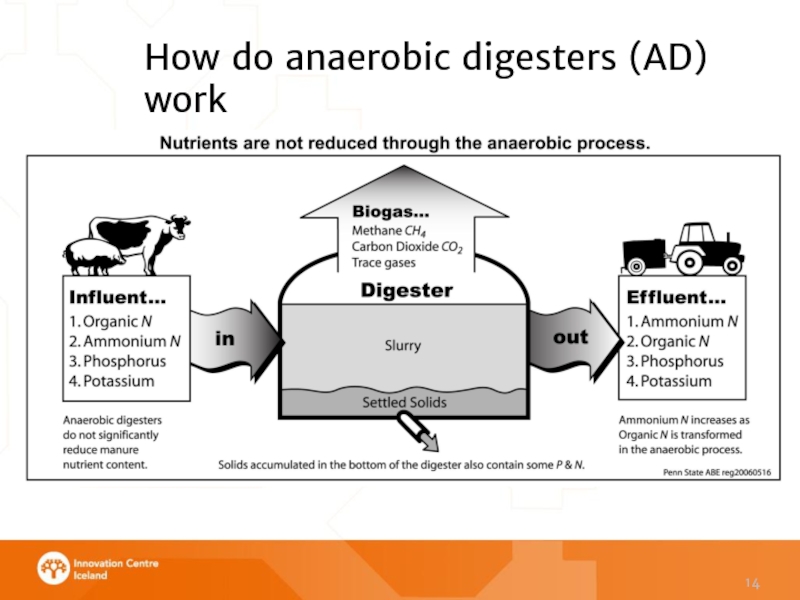

- 14. How do anaerobic digesters (AD) work

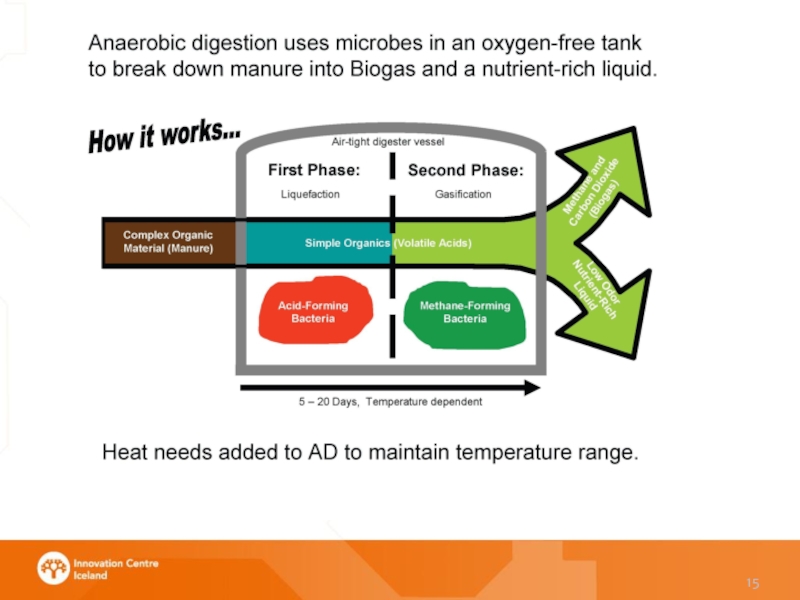

- 15. Слайд 15

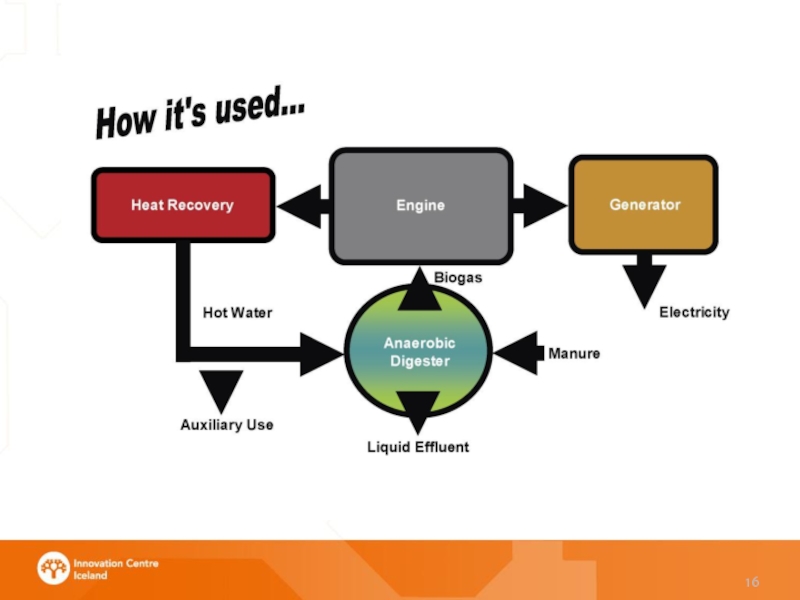

- 16. Слайд 16

- 17. Combination of waste– importance of C/N ratio•The

- 18. Methane production – how much? The

- 19. How much is used for energy

- 20. The aim of the EU is to

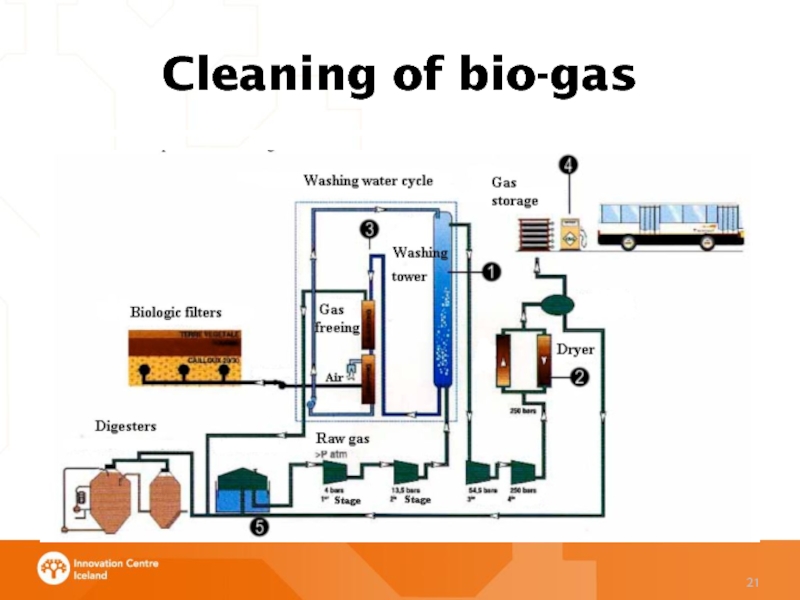

- 21. Cleaning of bio-gas

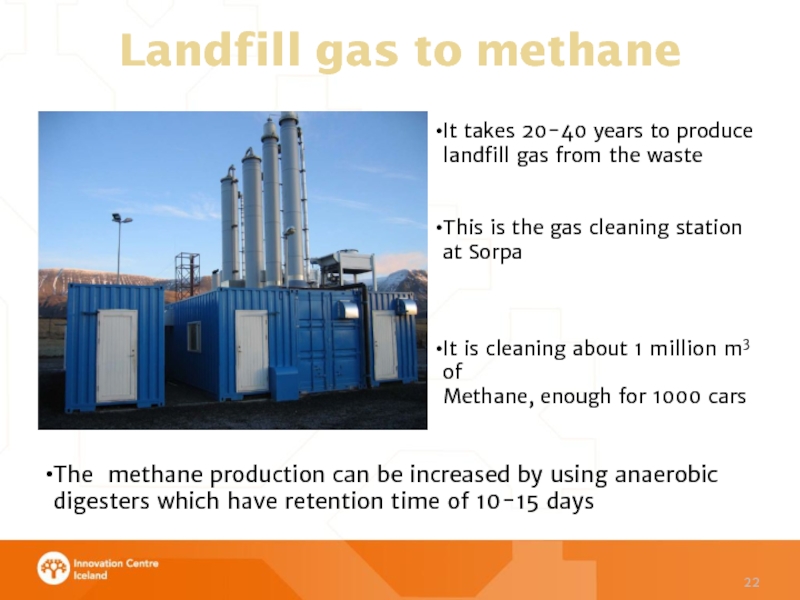

- 22. Landfill gas to methane It takes 20-40

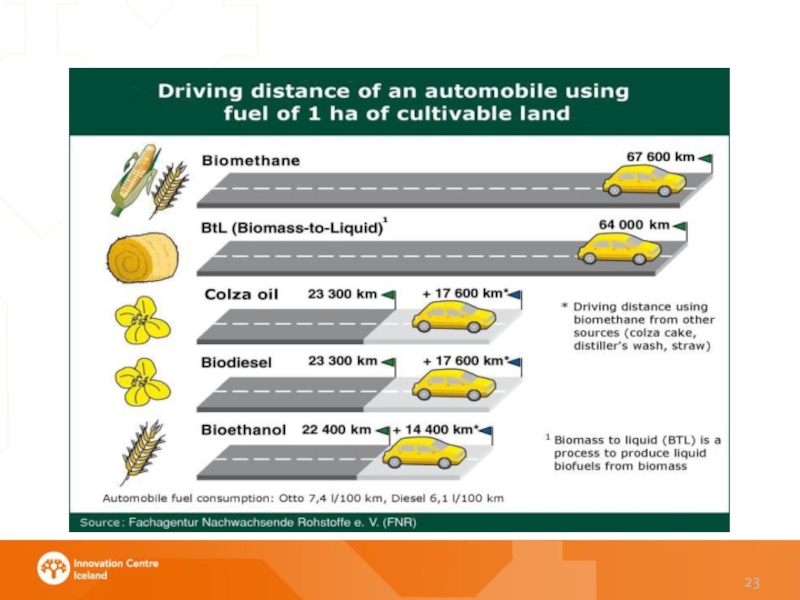

- 23. Слайд 23

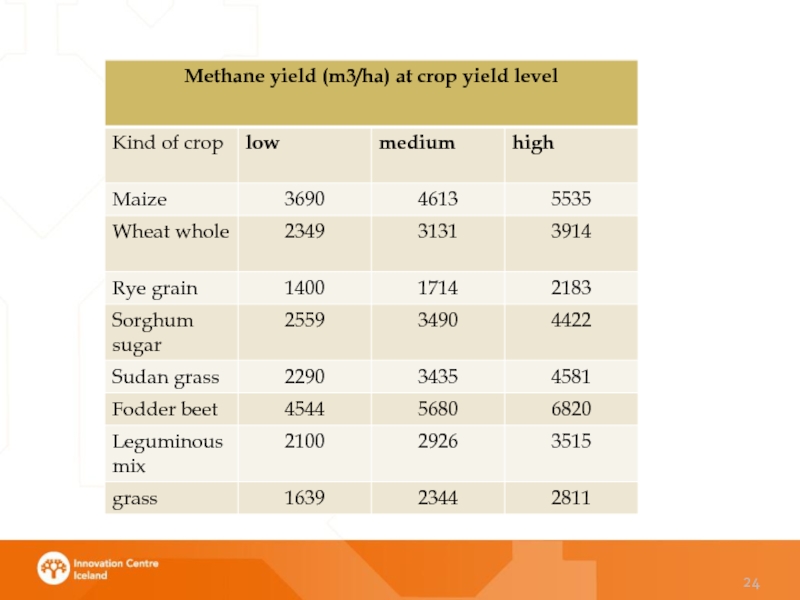

- 24. Слайд 24

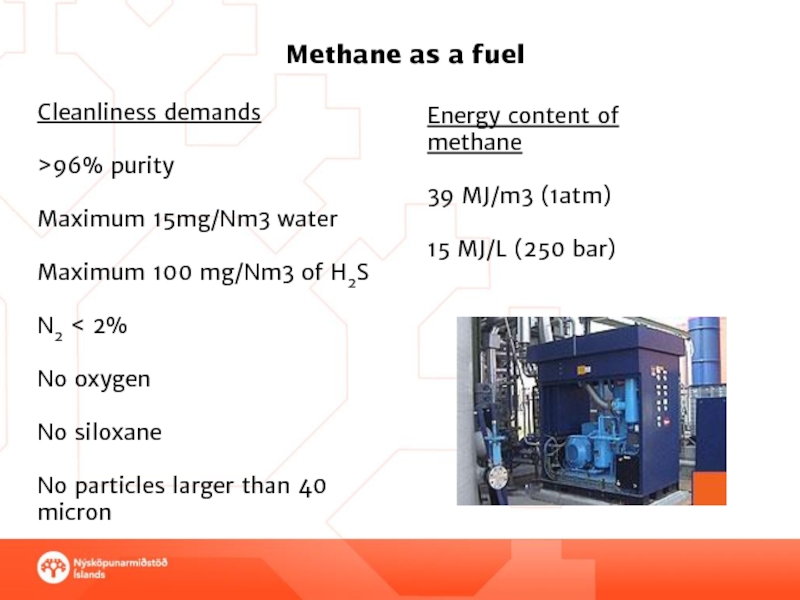

- 25. Methane as a fuelCleanliness demands>96% purityMaximum

- 26. Слайд 26

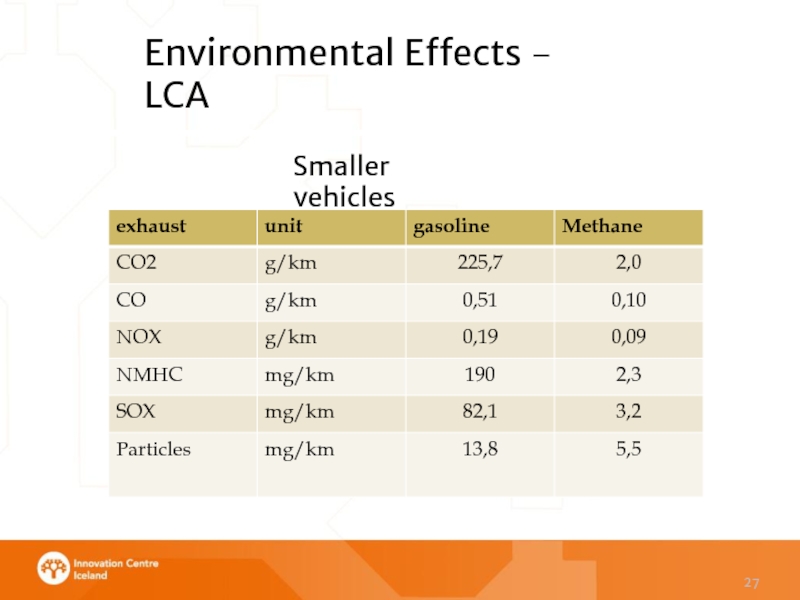

- 27. Environmental Effects – LCASmaller vehicles

- 28. Mechanical – ultrasound and pressure Chemical

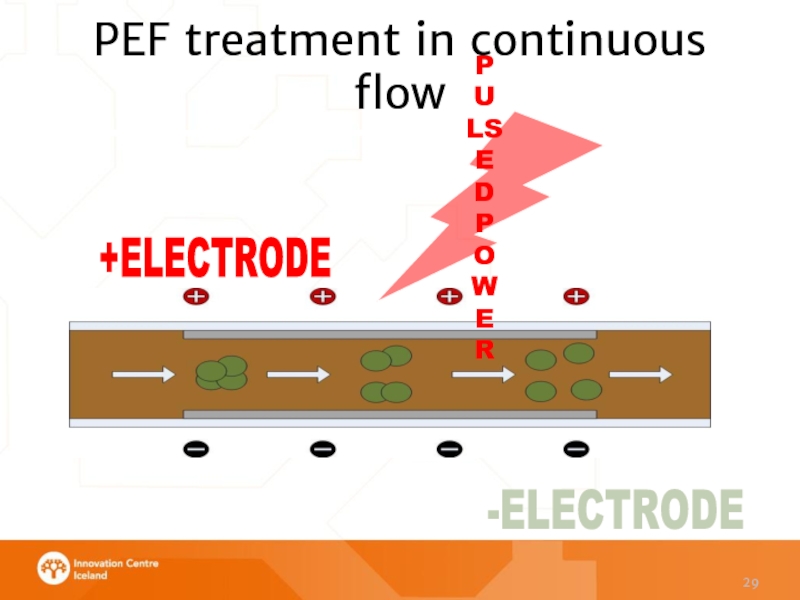

- 29. PEF treatment in continuous flow-ELECTRODE+ELECTRODEPULSED POWER

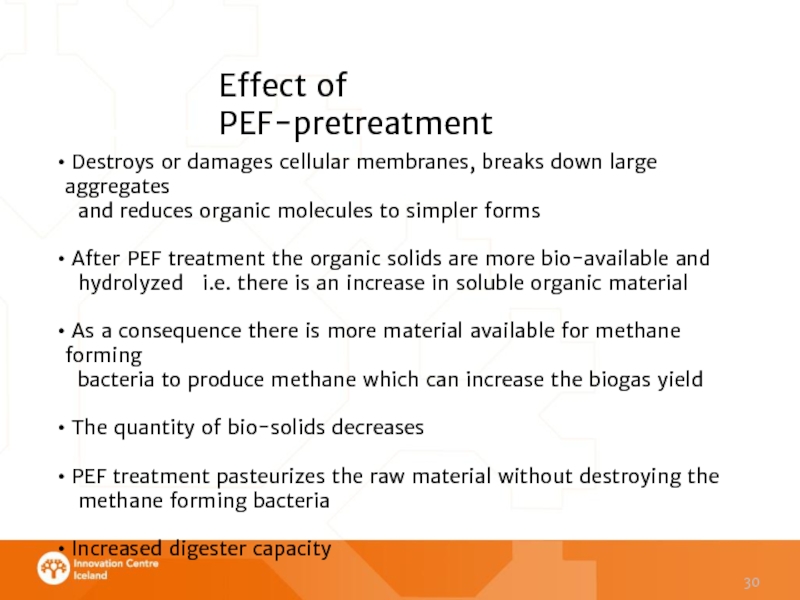

- 30. Destroys or damages cellular membranes, breaks

- 31. Bio- dieselAnimal fat and waste oilRapeseedAlgae oilsSoya

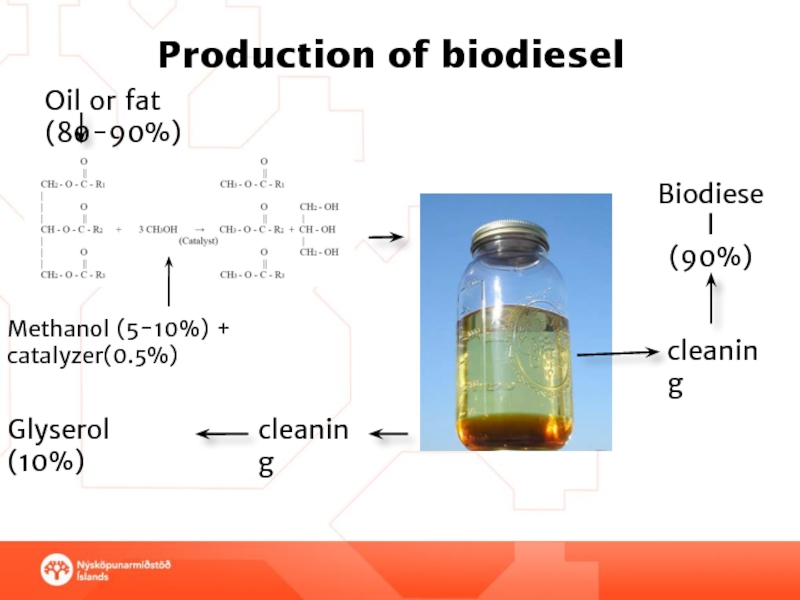

- 32. Production of biodieselBiodiesel(90%)Glyserol (10%)Methanol (5-10%) + catalyzer(0.5%)Oil or fat (80-90%)cleaningcleaning

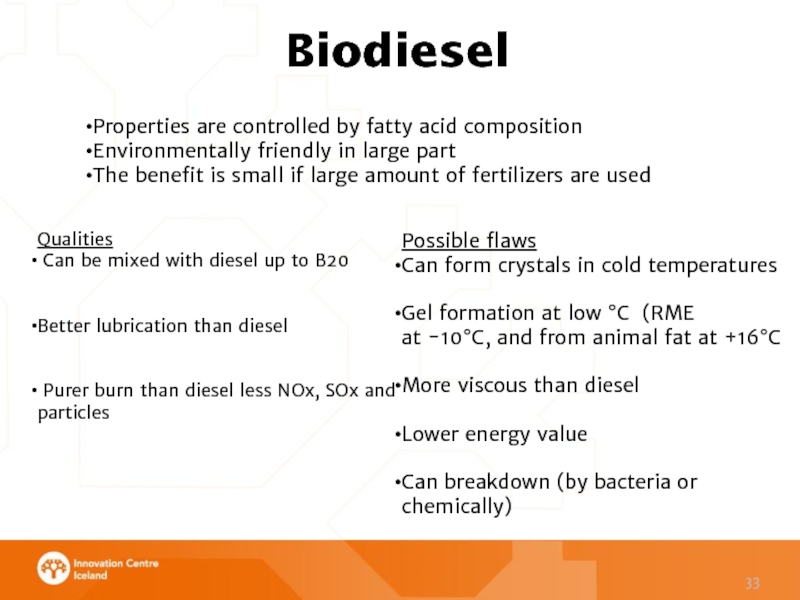

- 33. BiodieselPossible flawsCan form crystals in cold temperaturesGel

- 34. Скачать презентанцию

Слайды и текст этой презентации

Слайд 1Bioenergy - biofuels

Magnús Guðmundsson

Innovation Center of Iceland

Magnús Guðmundsson

Innovation Center

of Iceland

Слайд 2

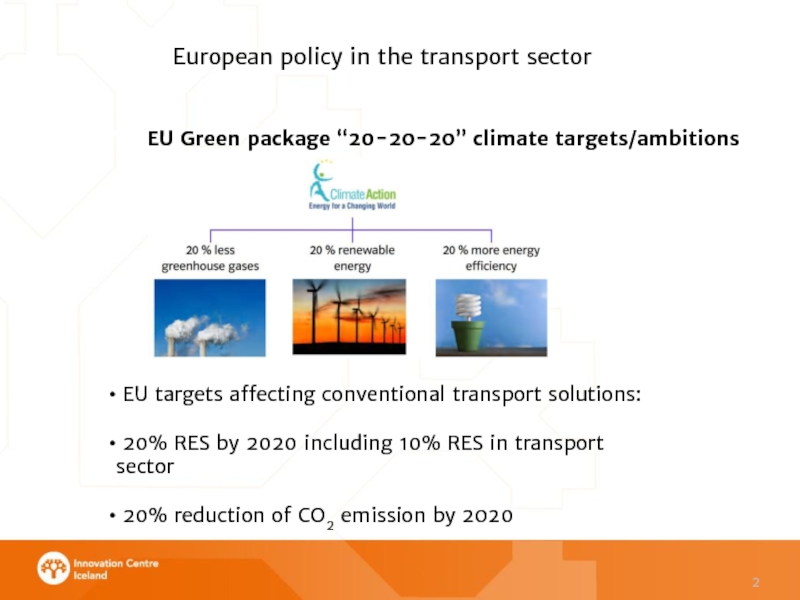

EU

Green package “20-20-20” climate targets/ambitions

EU targets affecting conventional

transport solutions: 20% RES by 2020 including 10% RES in transport sector

20% reduction of CO2 emission by 2020

European policy in the transport sector

Слайд 3Bio-fuels- definitions

Bio-fuels are made from sustainable raw materials, mainly

biomass, plant fat/oil and all kinds of organic waste from

agriculture, municipalities and industry. It is CO2 neutral!The use of bio-fuels are supposed to replace fossil fuels partially or totally leading to less pollution such as CO and dust.

Bio-fuels made with fermentation or chemical reactions are:

Bio-ethanol Bio-diesel Bio-gas (bio-methane)

Слайд 5Ethanol fermentation

Yeasts are mostly used today to ferment sugars to

ethanol: most common and can use many substrates

Also bacterias like

Zymomonas mobilis: higher ethanol tolerance but limited substrates (glucose, fructose)In some cases thermophilic bacteria is used

Thermophilic at 55°C are in use

Higher than 70°C is in development

Faster reactions but less tolerance

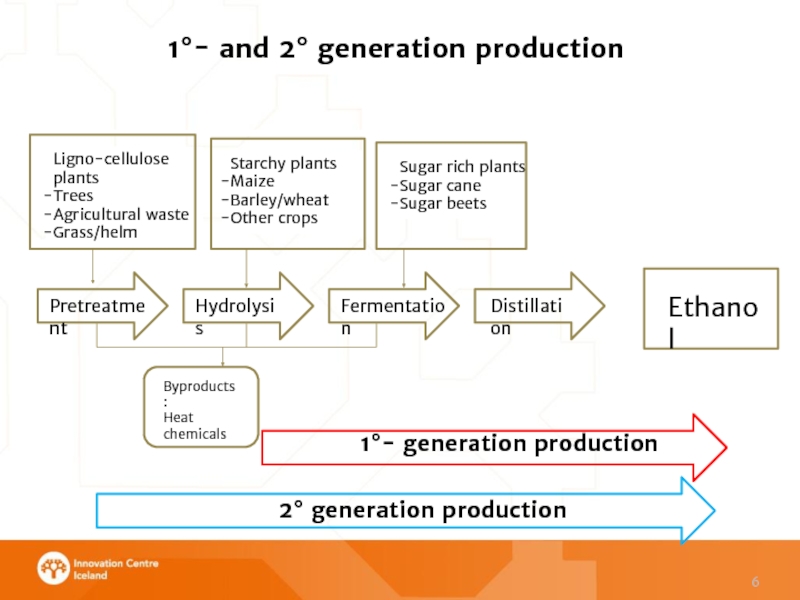

Слайд 61°- and 2° generation production

Ligno-cellulose plants

Trees

Agricultural waste

Grass/helm

Starchy plants

Maize

Barley/wheat

Other crops

Sugar rich

plants

Sugar cane

Sugar beets

Pretreatment

Hydrolysis

Fermentation

Distillation

Ethanol

1°- generation production

2° generation production

Byproducts:

Heat

chemicals

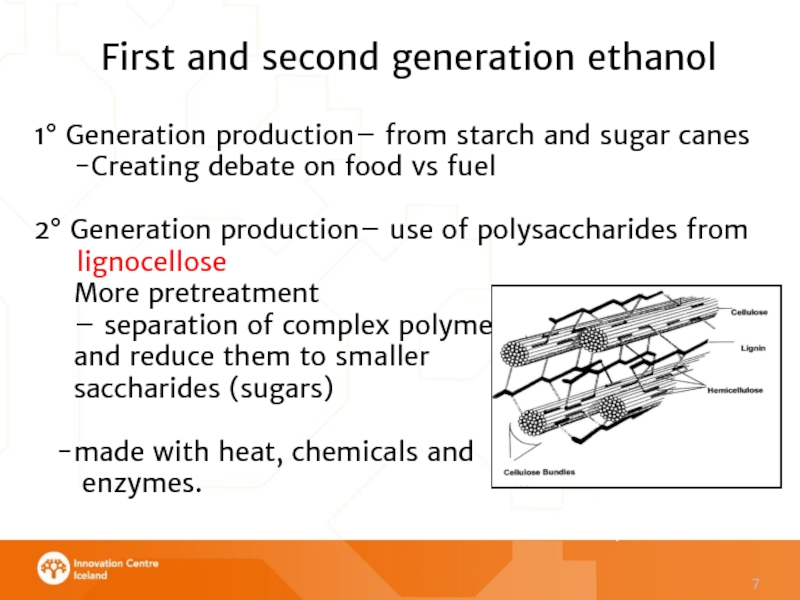

Слайд 7First and second generation ethanol

(from Toefl TU Berlin)

1° Generation production–

from starch and sugar canes

-Creating debate on food vs fuel

2°

Generation production– use of polysaccharides from lignocellose

More pretreatment

– separation of complex polymers

and reduce them to smaller

saccharides (sugars)

made with heat, chemicals and

enzymes.

Слайд 8Bio-Ethanol

Henry Ford started to use pure ethanol on “"Quadricycle" in

1896

USA produces more ethanol than Brasil

It is mainly produced from

maize (corn starch)First the starch is converted to sugars before it is fermented

USA production is more expensive than the production of Brazil

Слайд 11Methane

Anaerobic digestion with many types of bacteria

Produced from landfill gas

(buried waste) under uncontrolled

situations. Digestion time can be many

yearsProduced with anaerobic reactors under controlled situation.

Digestion time is 2-4 weeks

Слайд 12

Methane is produced by anaerobic digestion

•Methane forming bacteria need certain

conditions to thrive

-pH 6,4-7,2

- Temperature: Psycrophilic (0-20°C), mesophilic (30-35°C)

and thermophilic(> 55°C)- The ratio of C/N should be 25-30

- Moisture (> 65%)

The solid residue is a by-product

and a very good fertilizer

Organic matter

/ manure

Kolvetni

Prótein

fita

Acid forming

bacteria

Simple organic

acids

Acetic acid

Probionic acid

Succininic acid

Butyric acid

Formic acid

Methane forming

bacteria

Landfill and biogas

Methane 50-70%

CO2 25-50%

water

Ammoniac

H2S

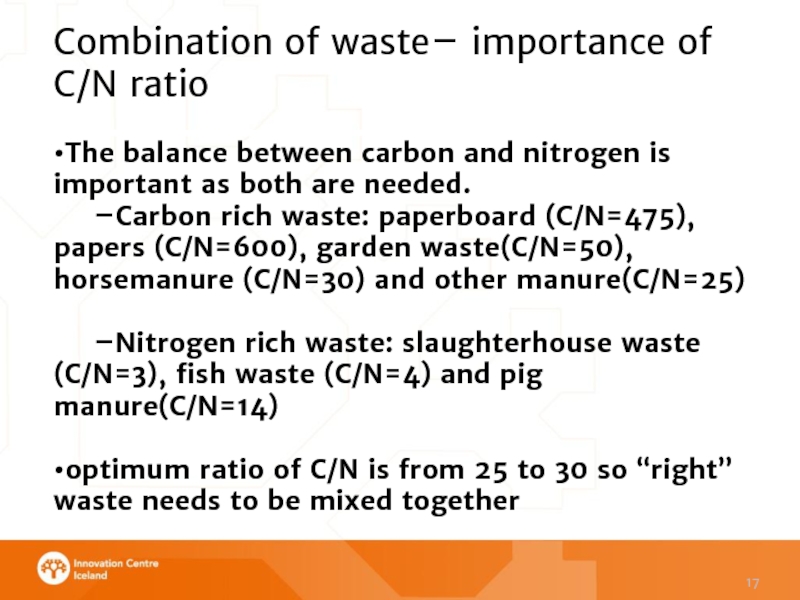

Слайд 17Combination of waste– importance of C/N ratio

•The balance between carbon

and nitrogen is important as both are needed.

–Carbon rich waste:

paperboard (C/N=475), papers (C/N=600), garden waste(C/N=50), horsemanure (C/N=30) and other manure(C/N=25)–Nitrogen rich waste: slaughterhouse waste (C/N=3), fish waste (C/N=4) and pig manure(C/N=14)

•optimum ratio of C/N is from 25 to 30 so “right” waste needs to be mixed together

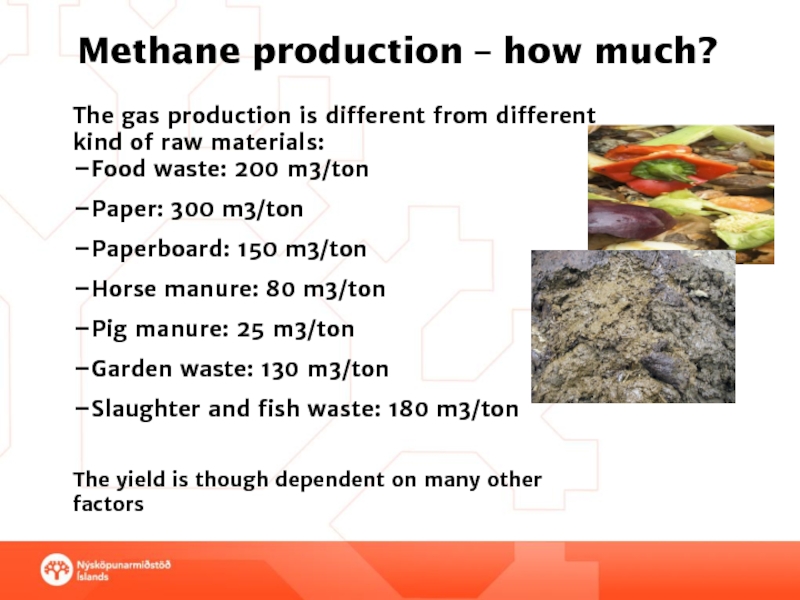

Слайд 18

Methane production – how much?

The gas production is different

from different kind of raw materials:

–Food waste: 200 m3/ton

–Paper: 300

m3/ton–Paperboard: 150 m3/ton

–Horse manure: 80 m3/ton

–Pig manure: 25 m3/ton

–Garden waste: 130 m3/ton

–Slaughter and fish waste: 180 m3/ton

The yield is though dependent on many other factors

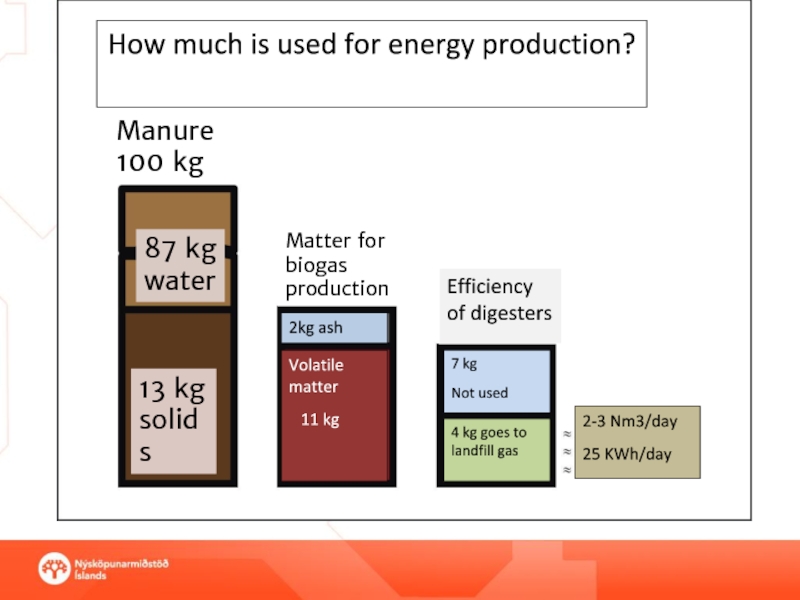

Слайд 19

How much is used for energy production?

Manure

100 kg

87 kg

water

13 kg

solids

Matter

for biogas production

2kg ash

Volatile matter

11 kg

Efficiency of digesters

7

kgNot used

4 kg goes to landfill gas

2-3 Nm3/day

25 KWh/day

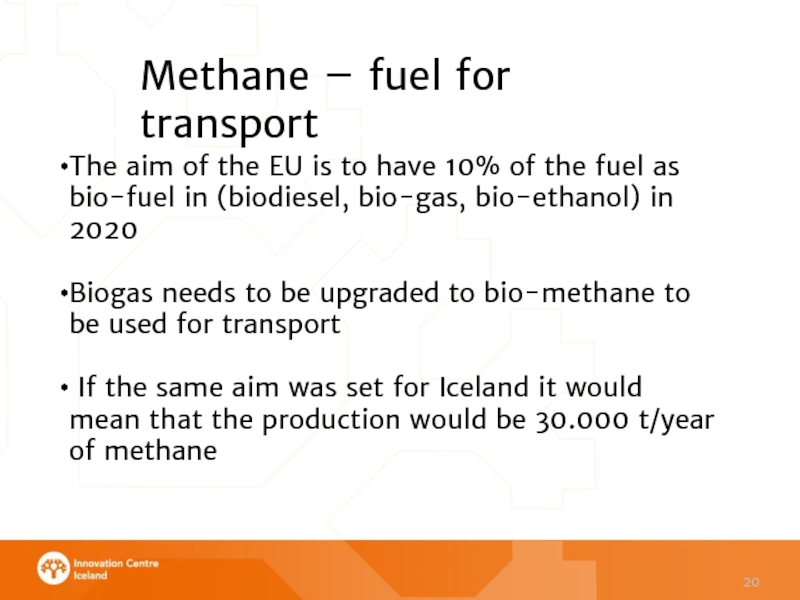

Слайд 20The aim of the EU is to have 10% of

the fuel as bio-fuel in (biodiesel, bio-gas, bio-ethanol) in 2020

Biogas

needs to be upgraded to bio-methane to be used for transportIf the same aim was set for Iceland it would mean that the production would be 30.000 t/year of methane

Methane – fuel for transport

Слайд 22Landfill gas to methane

It takes 20-40 years to produce landfill

gas from the waste

This is the gas cleaning station at

SorpaIt is cleaning about 1 million m3 of

Methane, enough for 1000 cars

The methane production can be increased by using anaerobic digesters which have retention time of 10-15 days

Слайд 25

Methane as a fuel

Cleanliness demands

>96% purity

Maximum 15mg/Nm3 water

Maximum 100 mg/Nm3

of H2S

N2 < 2%

No oxygen

No siloxane

No particles larger than 40

micronEnergy content of methane

39 MJ/m3 (1atm)

15 MJ/L (250 bar)

Слайд 28 Mechanical – ultrasound and pressure

Chemical – use of

alkali, acids and enzymes

Thermal – use of thermal hydrolysis

and microwaveElectrical – methods like PEF (Pulsed Electric Field)

Pretreatments of bio-waste for anaerobic digestion

Слайд 30 Destroys or damages cellular membranes, breaks down large aggregates

and reduces organic molecules to simpler forms

After

PEF treatment the organic solids are more bio-available and hydrolyzed i.e. there is an increase in soluble organic material

As a consequence there is more material available for methane forming

bacteria to produce methane which can increase the biogas yield

The quantity of bio-solids decreases

PEF treatment pasteurizes the raw material without destroying the

methane forming bacteria

Increased digester capacity

Effect of PEF-pretreatment

Слайд 31Bio- diesel

Animal fat and waste oil

Rapeseed

Algae oils

Soya beans

Other oily crops

Raw

material

The oil can be cold pressed to get the oil

Слайд 32Production of biodiesel

Biodiesel

(90%)

Glyserol (10%)

Methanol (5-10%) + catalyzer(0.5%)

Oil or fat (80-90%)

cleaning

cleaning

Слайд 33Biodiesel

Possible flaws

Can form crystals in cold temperatures

Gel formation at low

°C (RME

at -10°C, and from animal fat at +16°C

More viscous

than dieselLower energy value

Can breakdown (by bacteria or chemically)

Properties are controlled by fatty acid composition

Environmentally friendly in large part

The benefit is small if large amount of fertilizers are used

Qualities

Can be mixed with diesel up to B20

Better lubrication than diesel

Purer burn than diesel less NOx, SOx and particles