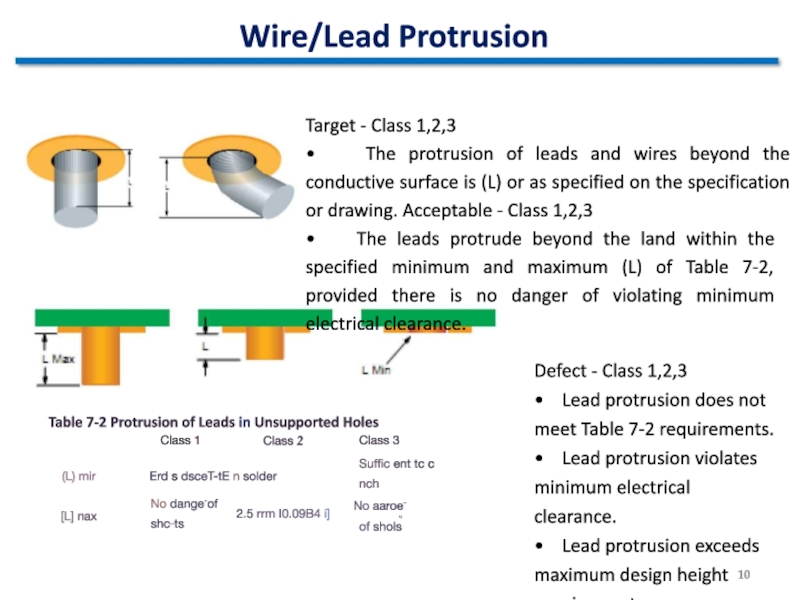

and wires beyond the conductive surface is (L) or as

specified on the specification or drawing. Acceptable - Class 1,2,3• The leads protrude beyond the land within the specified minimum and maximum (L) of Table 7-2, provided there is no danger of violating minimum electrical clearance.

Table 7-2 Protrusion of Leads in Unsupported Holes

Defect - Class 1,2,3

• Lead protrusion does not meet Table 7-2 requirements.

• Lead protrusion violates minimum electrical clearance.

• Lead protrusion exceeds maximum design height requirements.

10