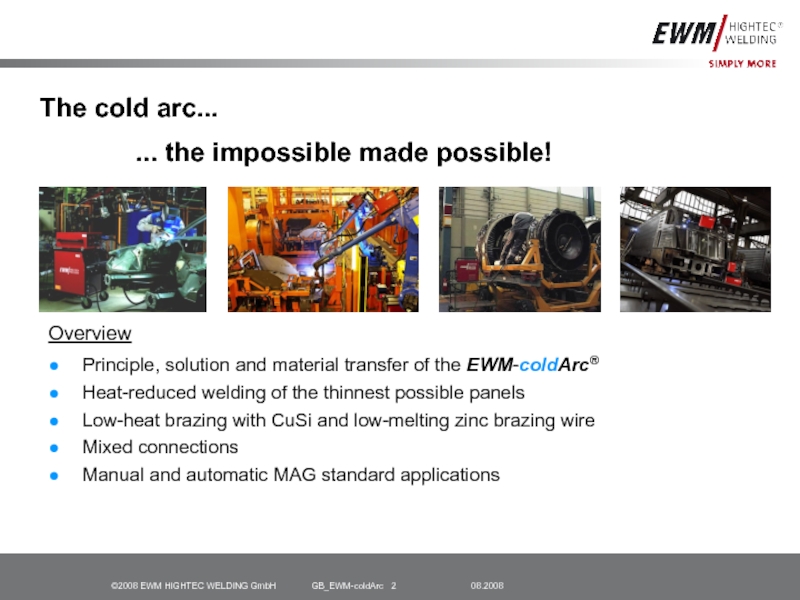

the impossible made possible!

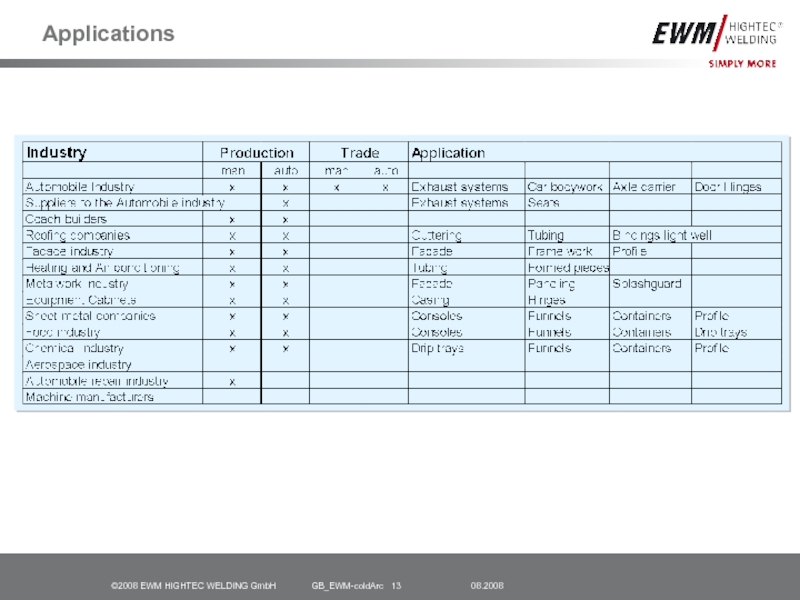

Overview

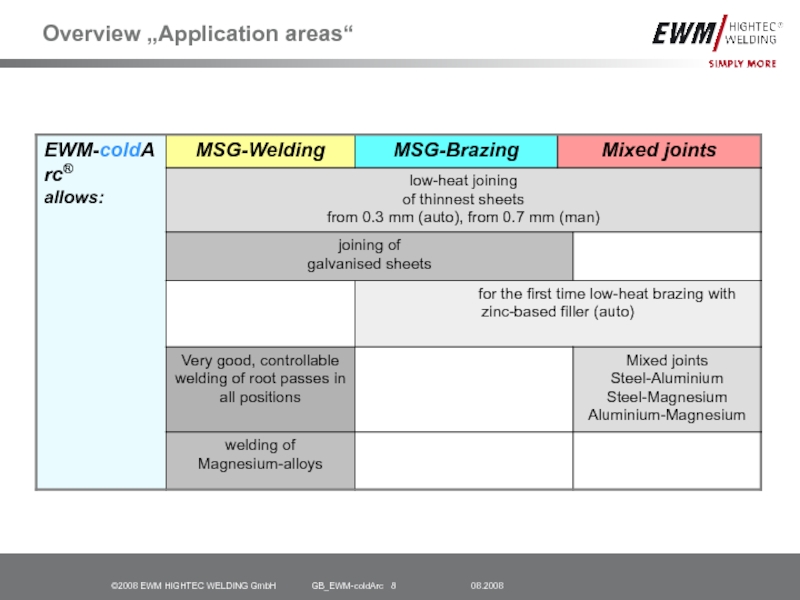

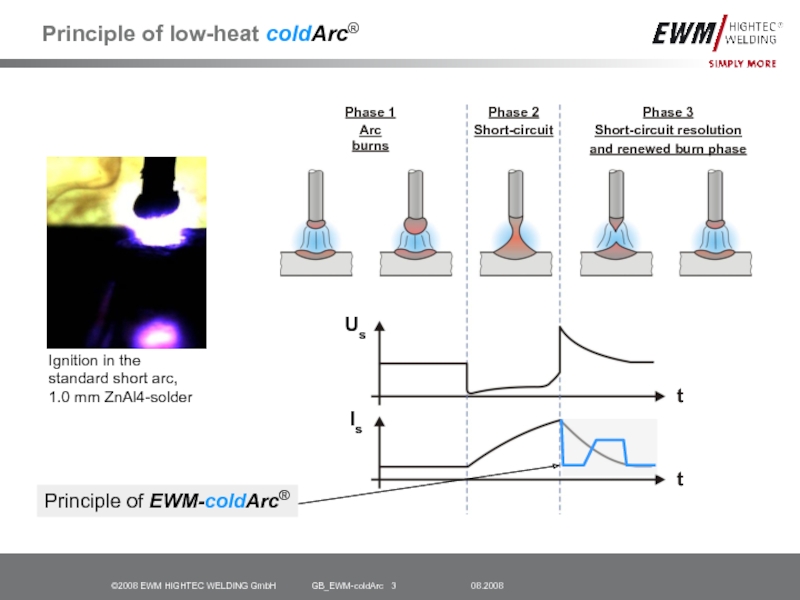

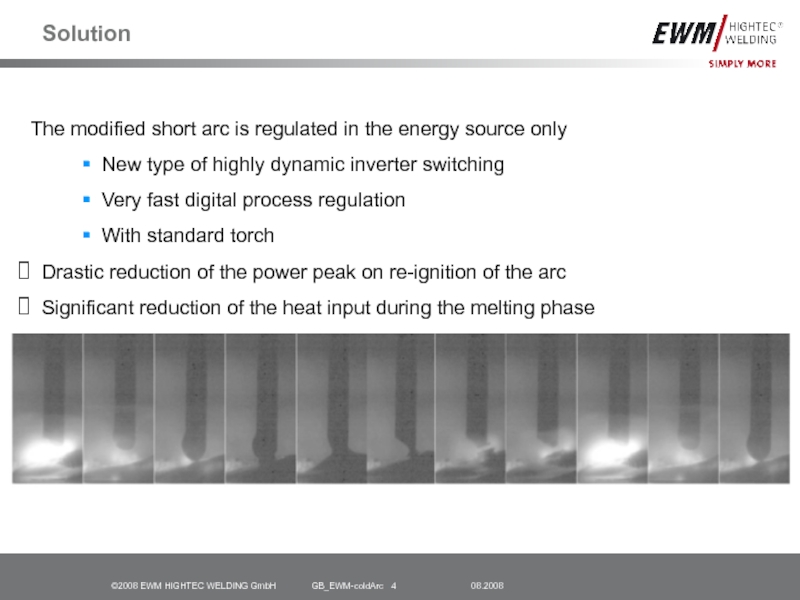

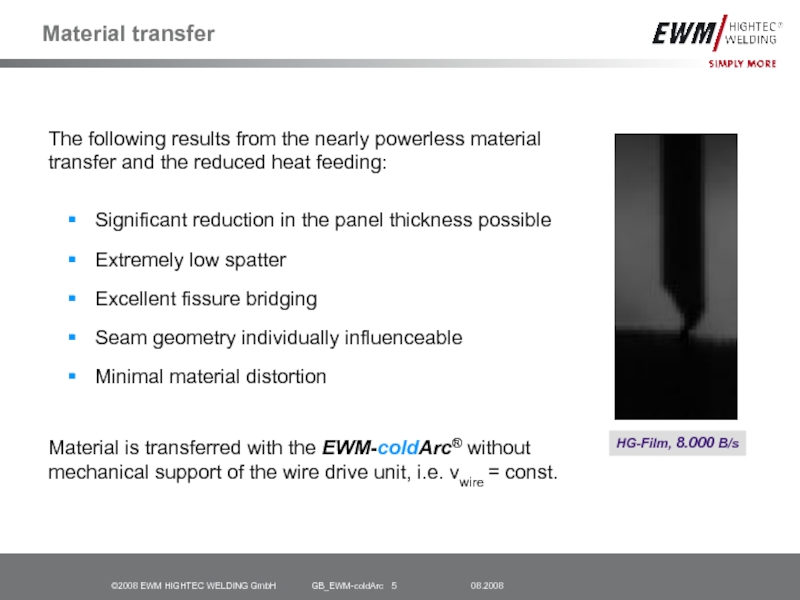

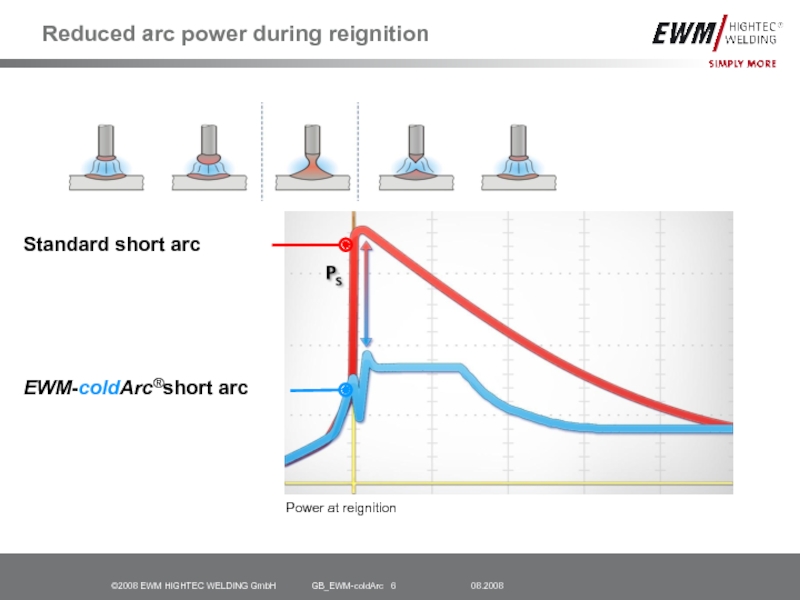

Principle, solution and material transfer of the

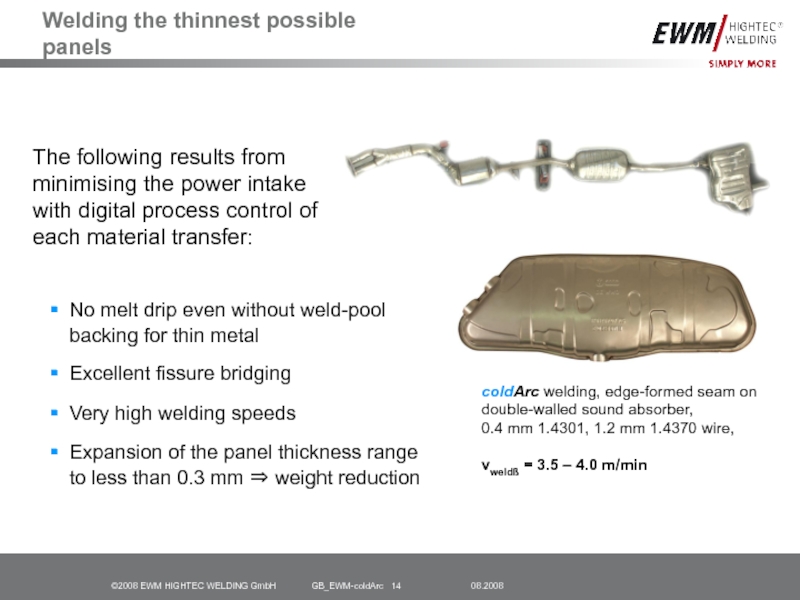

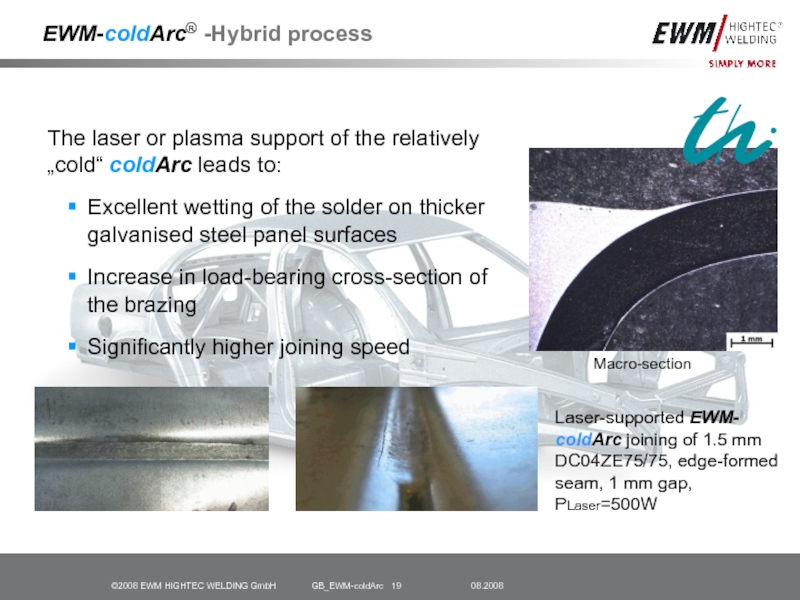

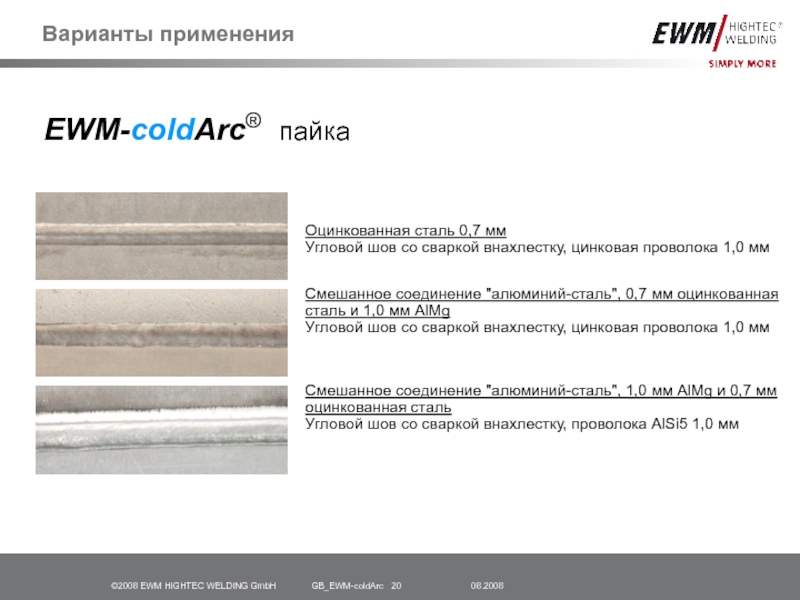

EWM-coldArc®Heat-reduced welding of the thinnest possible panels

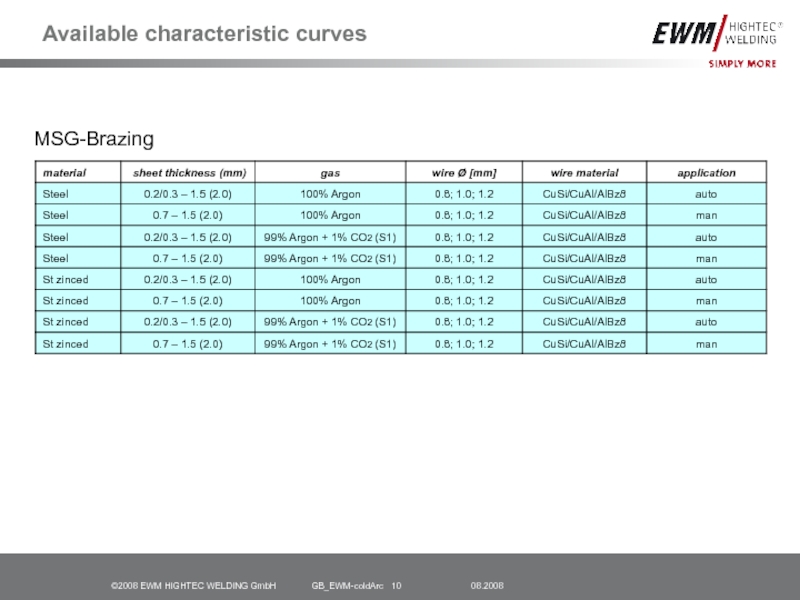

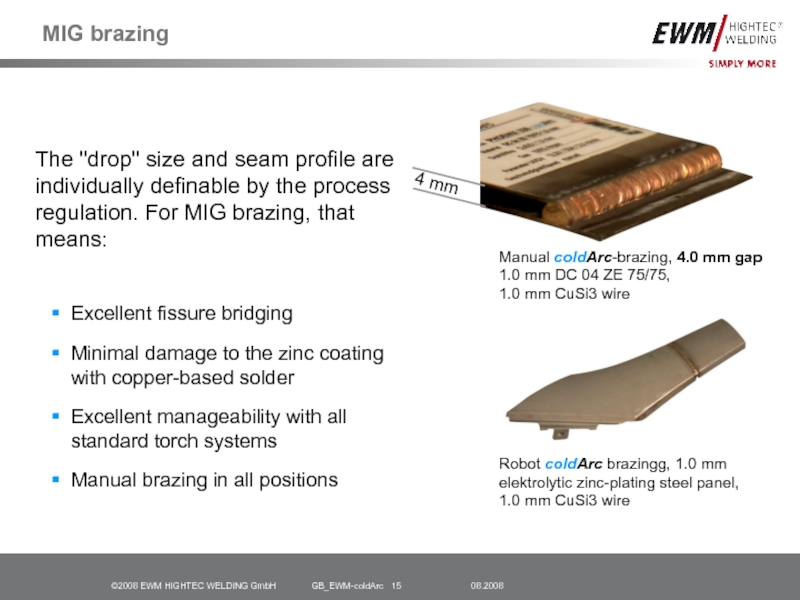

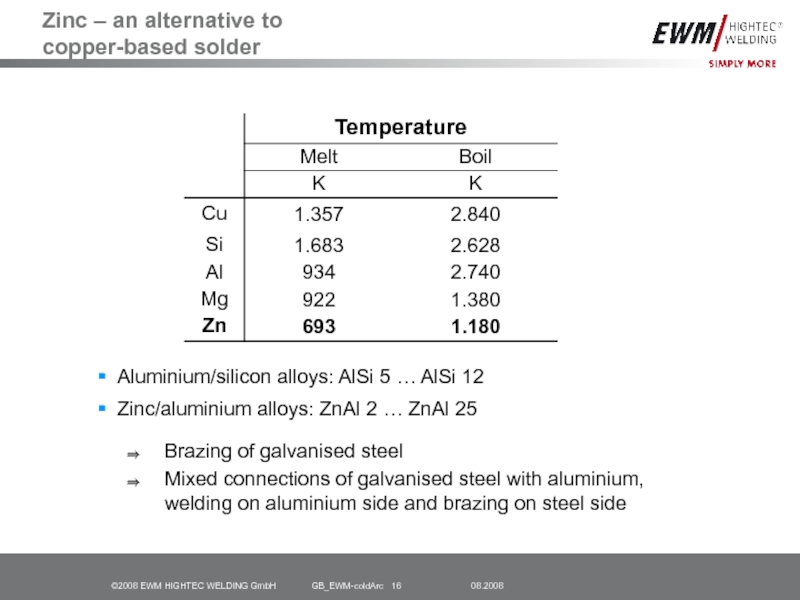

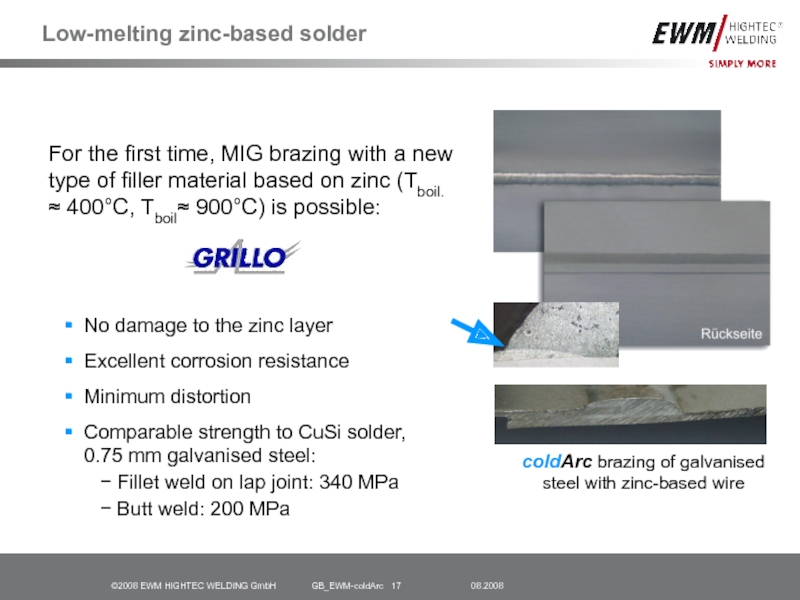

Low-heat brazing with CuSi and low-melting zinc brazing wire

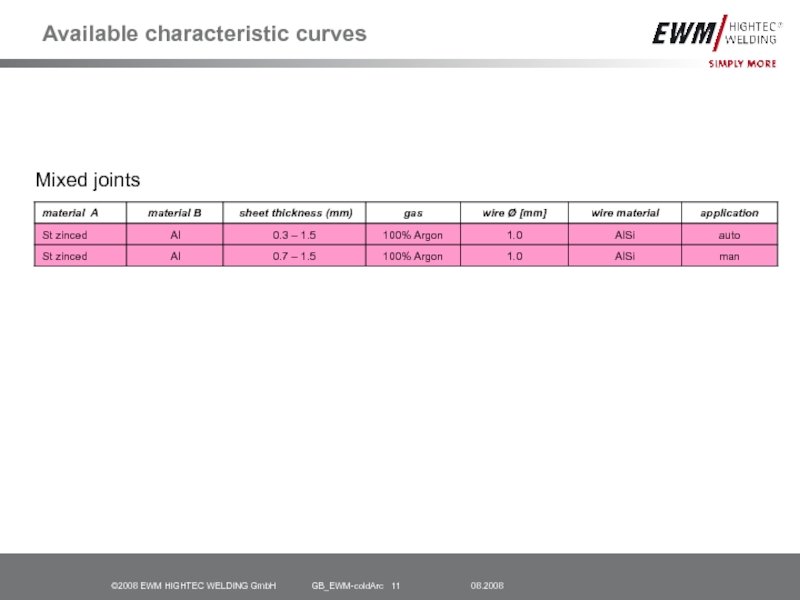

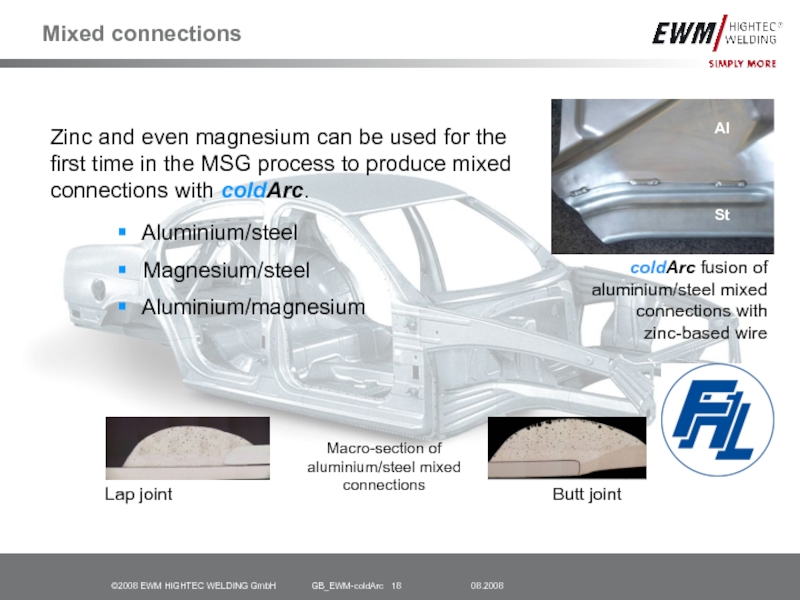

Mixed connections

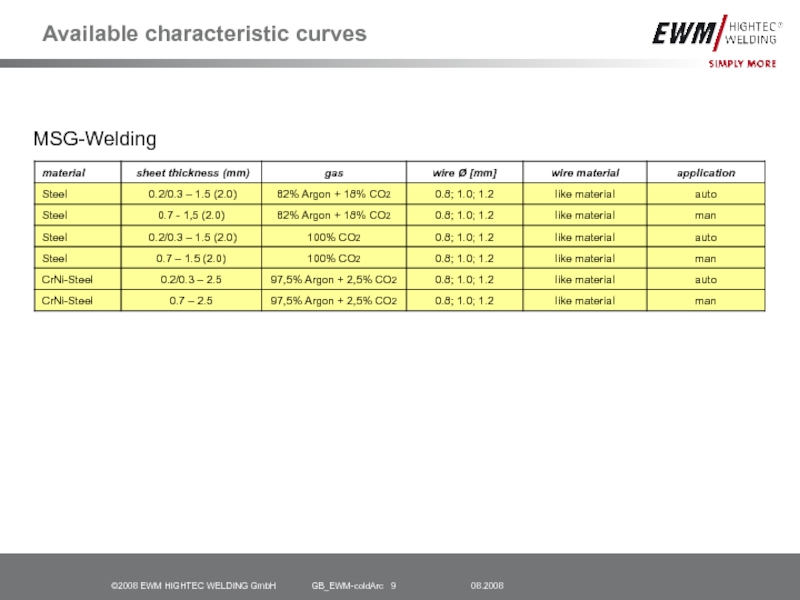

Manual and automatic MAG standard applications

![Low energy short arc

EWM- cold Arc ® voltage [V]KLBÜLBSLBRLB (Highspeed)forceArc®ILB = Pulsed arcKLB = Short arcÜLB = Transition arcSLB = Spray arcRLB = Rotating arc (Highspeed)coldArc®ILBArc types voltage [V]KLBÜLBSLBRLB (Highspeed)forceArc®ILB = Pulsed arcKLB = Short arcÜLB = Transition arcSLB = Spray arcRLB = Rotating arc (Highspeed)coldArc®ILBArc types](/img/thumbs/6d989c15716dda73b191f212bc82f09e-800x.jpg)