Разделы презентаций

- Разное

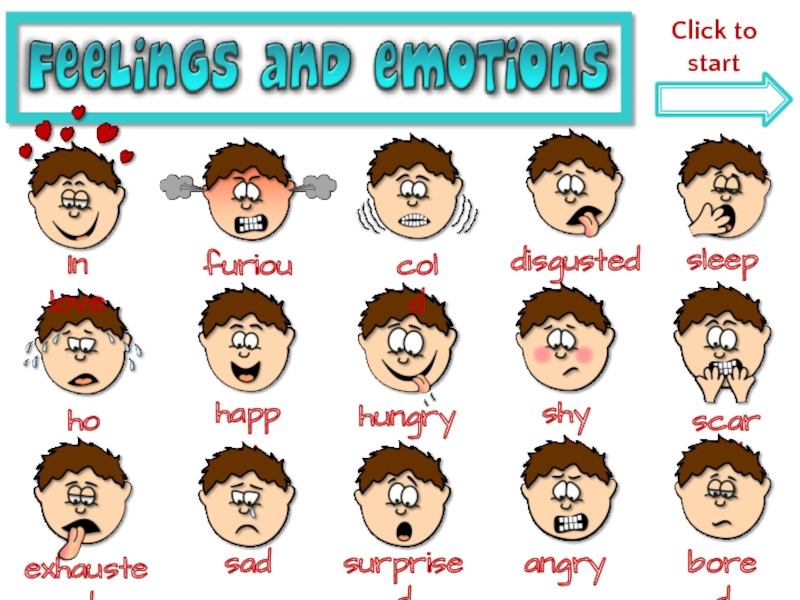

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

MAN Diesel PrimeServ Academy Fuel Oil System

Содержание

- 1. MAN Diesel PrimeServ Academy Fuel Oil System

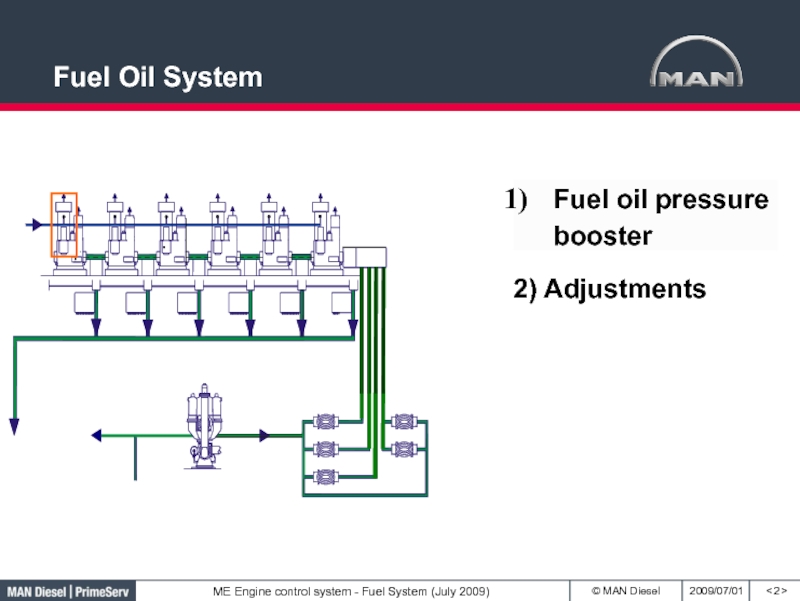

- 2. < > Fuel oil pressure booster2) AdjustmentsFuel Oil System

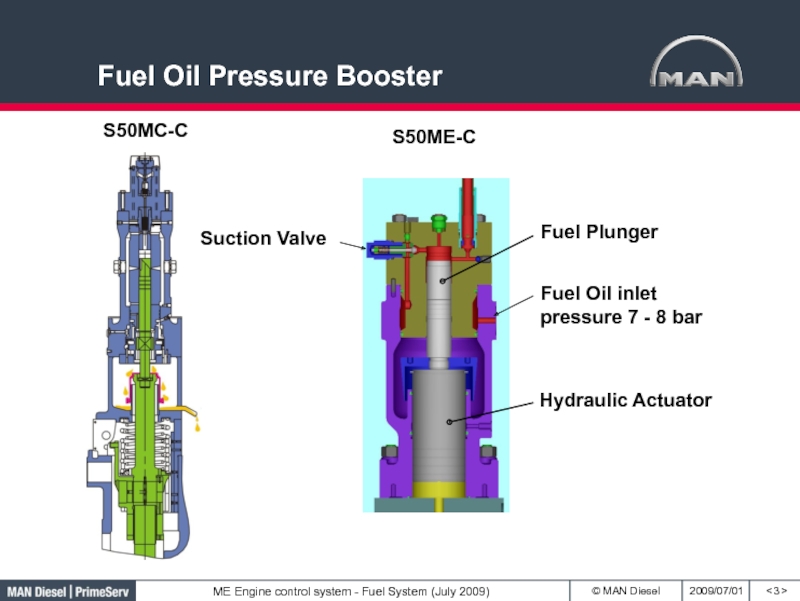

- 3. Fuel Oil Pressure Booster < >

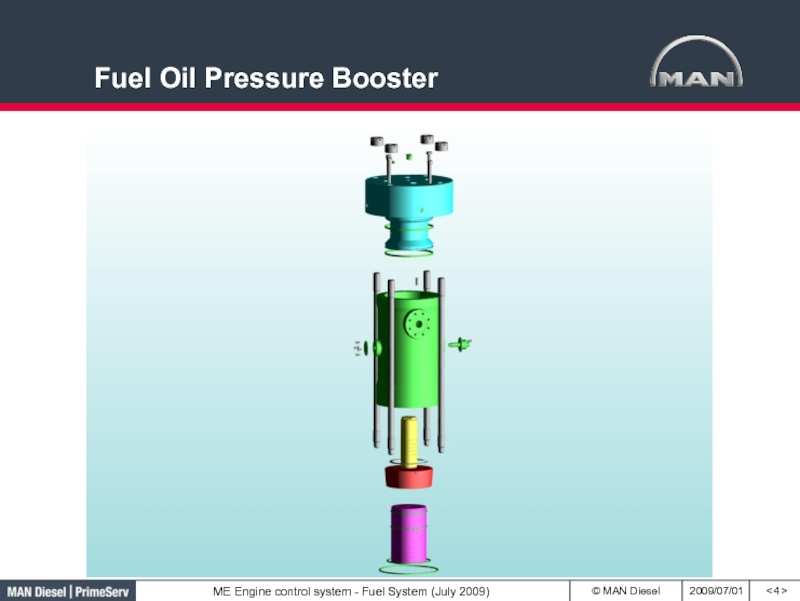

- 4. Fuel Oil Pressure Booster< >

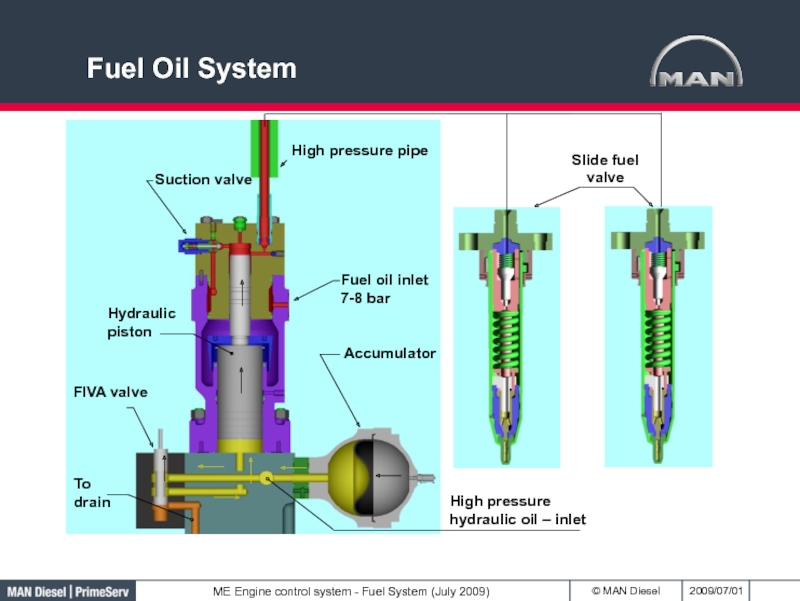

- 5. To drainAccumulatorFuel oil inlet 7-8 barSuction valveFIVA

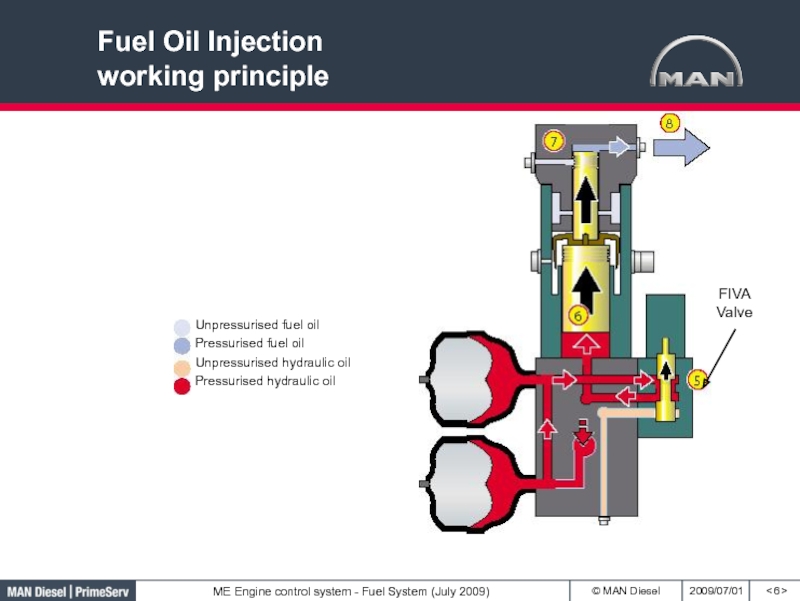

- 6. Fuel Oil Injection working principle< >FIVAValve

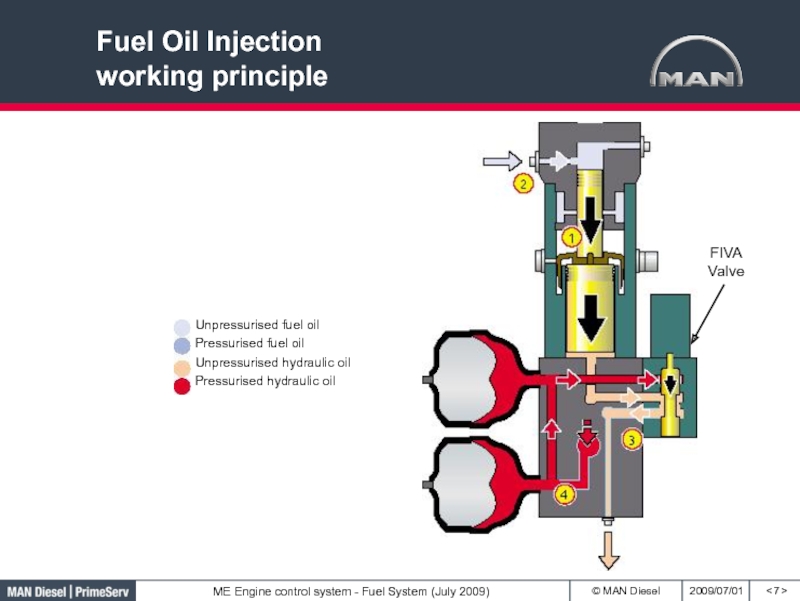

- 7. Fuel Oil Injection working principle< >FIVA Valve

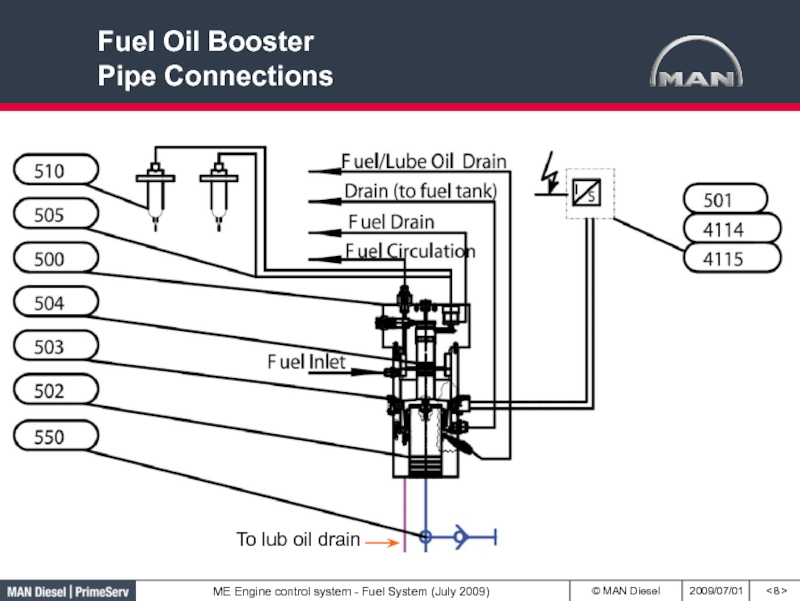

- 8. Fuel Oil Booster Pipe Connections< >To lub oil drain

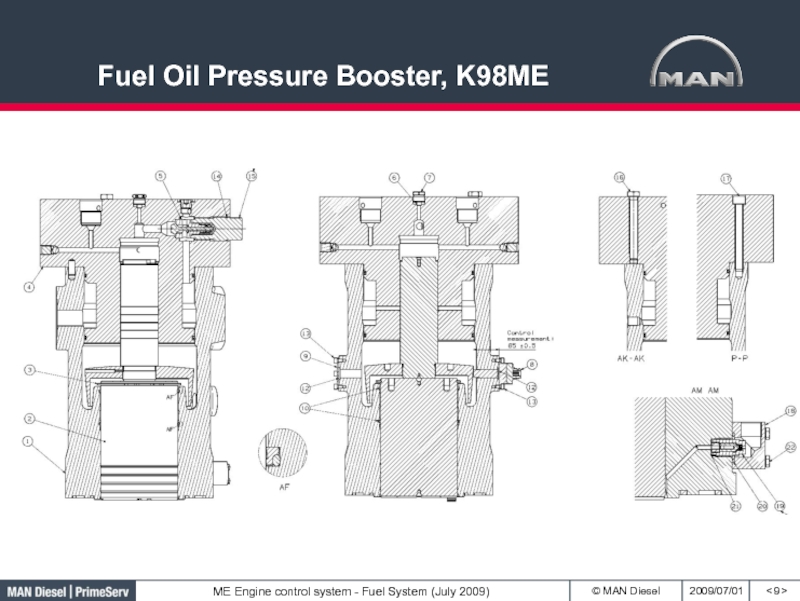

- 9. Fuel Oil Pressure Booster, K98ME< >

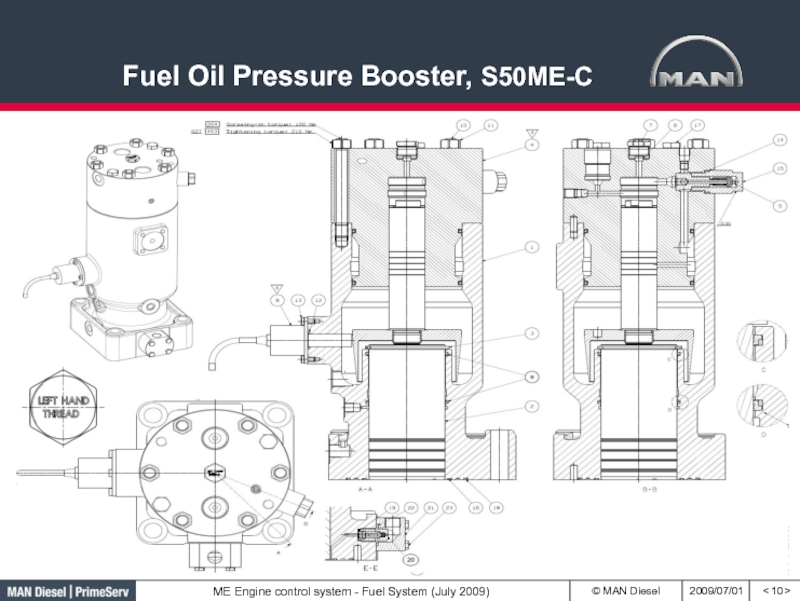

- 10. Fuel Oil Pressure Booster, S50ME-C < >

- 11. FIVA Valve Position Control< >Requested position (table)

- 12. Supervision of FIVA Feedback Signal & Plunger

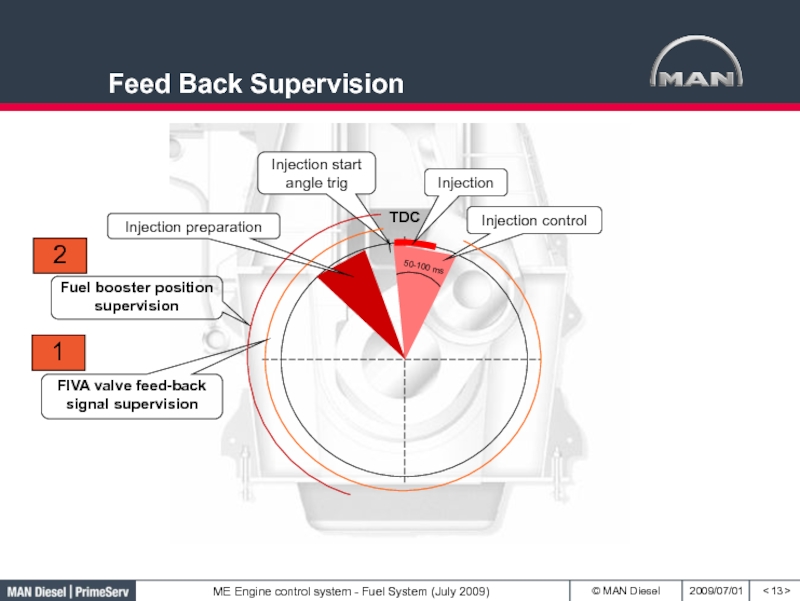

- 13. < >FIVA valve feed-back signal supervision50-100 msFuel booster position supervision21Feed Back Supervision

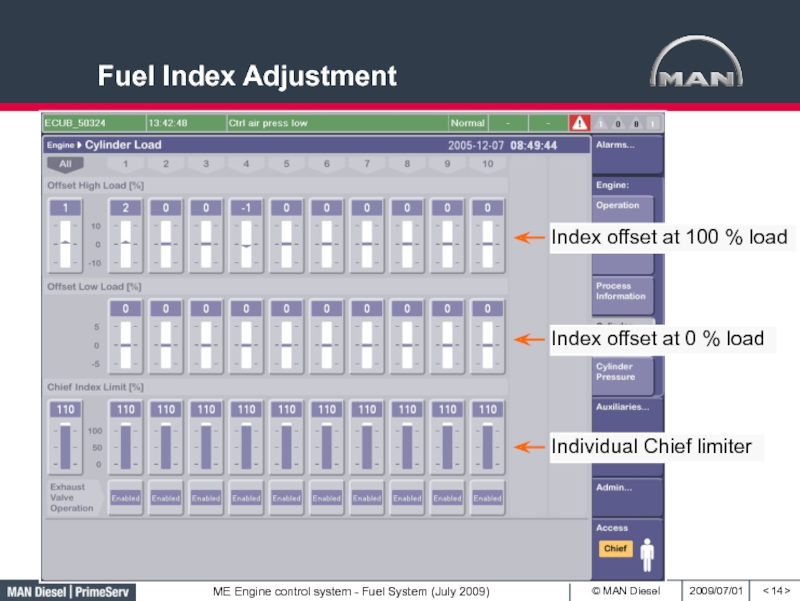

- 14. Fuel Index Adjustment< >

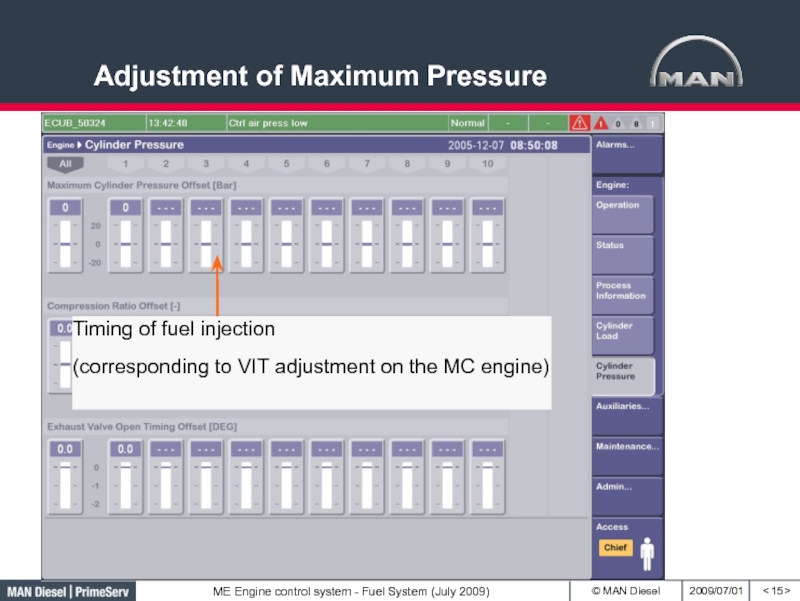

- 15. Adjustment of Maximum Pressure< >Timing of fuel injection(corresponding to VIT adjustment on the MC engine)

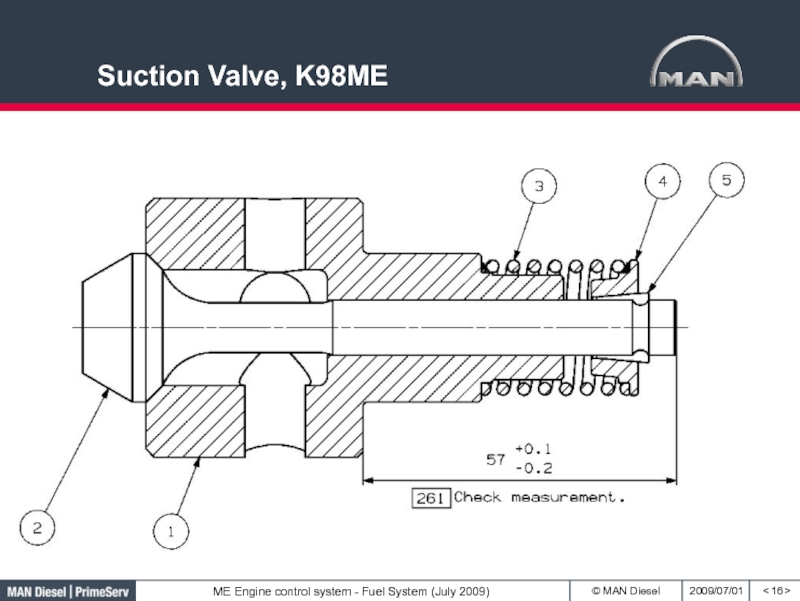

- 16. Suction Valve, K98ME< >

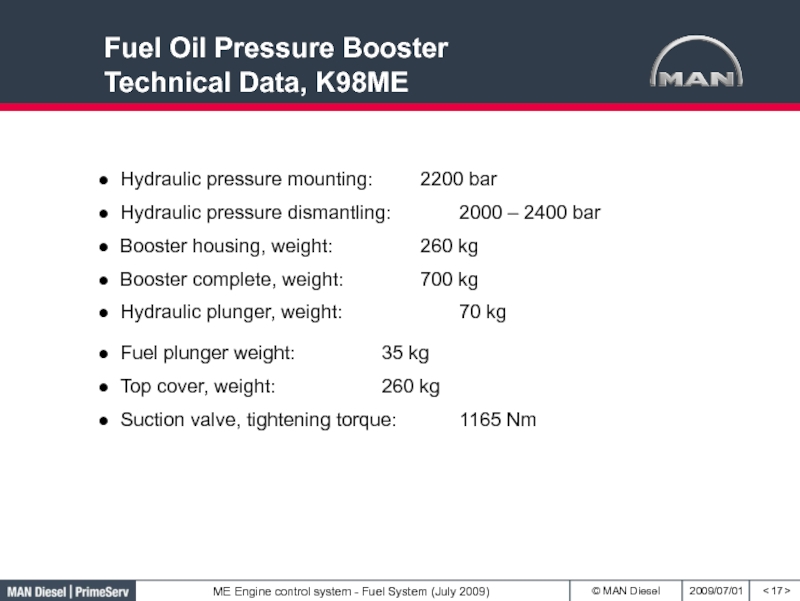

- 17. Fuel Oil Pressure Booster Technical Data, K98ME<

- 18. Скачать презентанцию

Слайды и текст этой презентации

Слайд 5To drain

Accumulator

Fuel oil inlet 7-8 bar

Suction valve

FIVA valve

Slide fuel valve

Hydraulic

piston

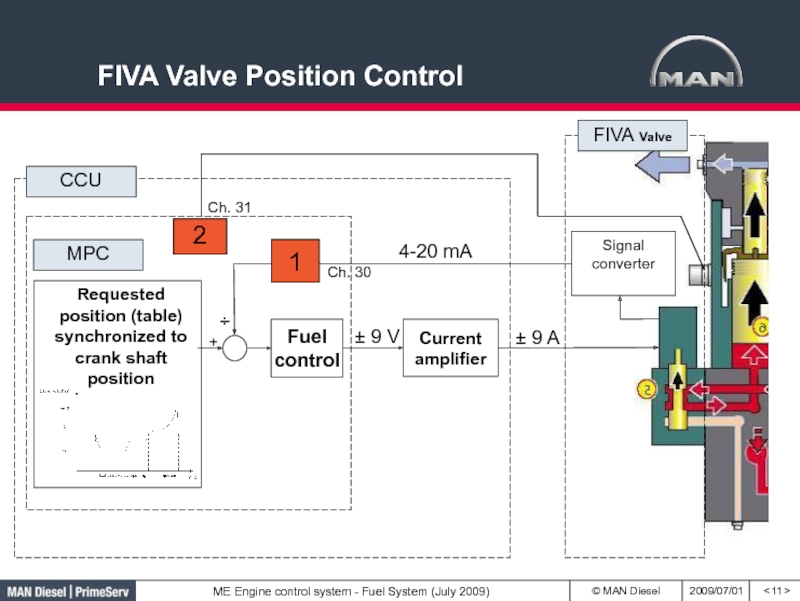

Слайд 11FIVA Valve Position Control

< >

Requested position (table) synchronized to crank

shaft position

+

Signal converter

FIVA Valve

MPC

CCU

± 9 V

± 9

A÷

4-20 mA

2

1

Ch. 31

Ch. 30

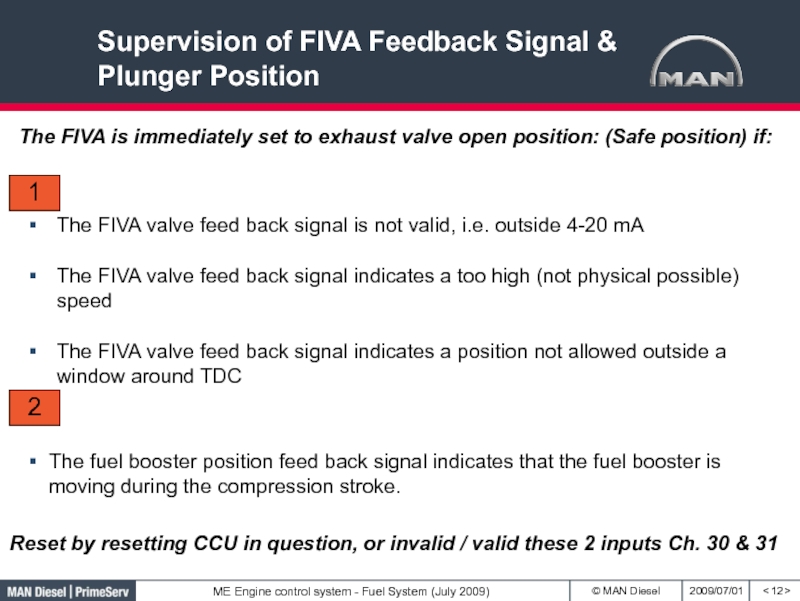

Слайд 12Supervision of FIVA Feedback Signal & Plunger Position

< >

The FIVA

valve feed back signal is not valid, i.e. outside 4-20

mAThe FIVA valve feed back signal indicates a too high (not physical possible) speed

The FIVA valve feed back signal indicates a position not allowed outside a window around TDC

2

The fuel booster position feed back signal indicates that the fuel booster is moving during the compression stroke.

The FIVA is immediately set to exhaust valve open position: (Safe position) if:

1

Reset by resetting CCU in question, or invalid / valid these 2 inputs Ch. 30 & 31

Слайд 13< >

FIVA valve feed-back signal supervision

50-100 ms

Fuel booster position supervision

2

1

Feed

Back Supervision

Слайд 15Adjustment of Maximum Pressure

< >

Timing of fuel injection

(corresponding to VIT

adjustment on the MC engine)

Слайд 17Fuel Oil Pressure Booster

Technical Data, K98ME

< >

Hydraulic pressure mounting: 2200

bar

Hydraulic pressure dismantling: 2000 – 2400 bar

Booster housing, weight: 260

kgBooster complete, weight: 700 kg

Hydraulic plunger, weight: 70 kg

Fuel plunger weight: 35 kg

Top cover, weight: 260 kg

Suction valve, tightening torque: 1165 Nm