large and diverse fleet of Controlled Atmosphere Containers, meeting various

green products storage and transportation needs.

Advantages of the proposed CMA CGM CA fleet:

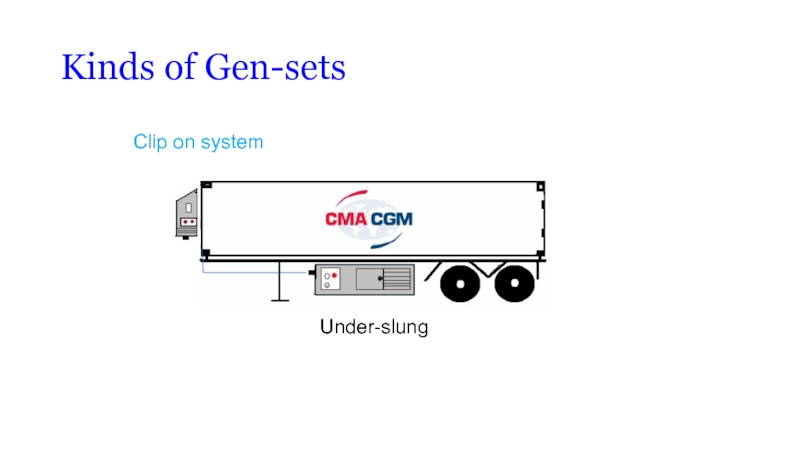

Integrated with the Reefer, uses the main power to operate

Transparency assured by built in sensors

Scrubbing CO2 without using atmosphere air

Lower dependency on Container’s age

BENEFITS

Ensure product quality

Controlled atmosphere technology controls the atmosphere inside containers.

Enhanced functionality to help slow down the ripening process of fruits and vegetables by removing ethylene.

Extended time for distribution at destination, and reaching markets with longer transit times

By accurately controlling the temperature and the atmosphere surrounding the cargo, shelf life of fruits can now be extended.

Delivery to remote markets and new destinations made possible.

Technology to manage the way your fruit cargo breathes and increase shelf-life