Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

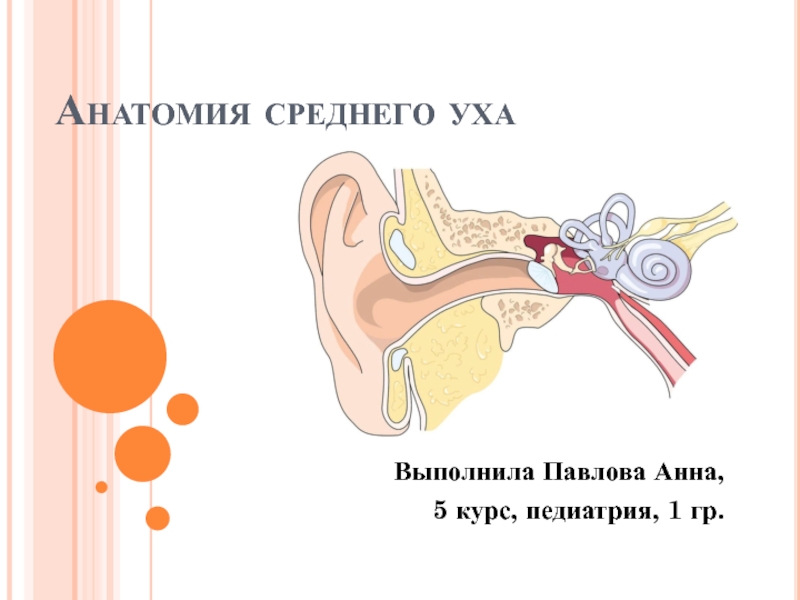

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Pasta Production

Содержание

- 1. Pasta Production

- 2. Preview

- 3. IntroductionPasta is popular because it…Is nutritiousIs convenient to buy and prepareHas a long shelf life

- 4. Inputs: IngredientsSemolina made from durum wheat WaterSalt

- 5. Inputs: IngredientsOptional:Eggs Spinach, tomato puree, chilli, mushrooms

- 6. Selection of SemolinaSemolina preferential to other flours

- 7. Combining ingredientsThree steps involveMixingProcessingExtruding

- 8. Combining ingredients: Pre-mixingIngredients flows into mixer is

- 9. Combining ingredients: MixingBubbles are removed by a

- 10. Mixing Calculation Must consider energy balance of

- 11. Combining ingredients: ExtrusionGluten matrix develops, assuming dough was sufficiently hydrated

- 12. ExtrusionAn extruder ____ the dough.ConveyCompactsKneadsRelaxesExtrudes

- 13. ExtrusionHydrated semolina mixture drops directly onto the

- 14. Extrusion: Challenges yetDifficult to form uniformly kneaded

- 15. ExtrusionLong pasta, like spaghetti are allowed a

- 16. Extrusion Die is used with an insert

- 17. Extrusion Long pastas are left to stand

- 18. DryingPurpose: to reduce moisture content to 12%

- 19. DryingFour factors involved:HumidityTemperatureTime exposure to heatAir flowAir flow and time exposure affects humidity and temperature

- 20. Drying: Air flowDirect contact between air and

- 21. Drying: Humidity Wet hot air (40-70% w/w) Prevent product from cracking at high temperatures

- 22. Drying: Exposure Time High temperatures requires shorter

- 23. Drying: Temperature Needs to be regulated because

- 24. Drying: Temperature RegulationsShort pastas are regulated by:Being

- 25. Use of Ultra High TemperatureApplication of Ultra-High

- 26. Improper cooling?Damage the packagingContaminated productBrittle product

- 27. Nutritional and Sensory QualityNutritiousCarbohydratesProteinVitamin BIronFolic acidNot fattening itself

- 28. Nutritional and Sensory QualityIdeal food for diabetics,

- 29. Nutritional and Sensory QualityYellowness of pasta determine

- 30. Nutritional and Sensory QualityCooking should not exceed

- 31. SummaryMixing, extruding, and drying are required in

- 32. SummaryDrying creates a moisture gradientReduces required drying

- 33. Photo Referenceshttp://www.food-info.net/images/pasta/pasta.jpghttps://files.nyu.edu/avl236/public/Flat%20Noodles.jpghttps://files.nyu.edu/avl236/public/pasta.JPGhttp://bombaybazar.ie/images/semolina-19582.jpghttp://thinkcommon.com/blog/wp-content/uploads/2009/05/water.jpghttp://www.wholesaleitalianfood.com/media/catalog/category/file_6.JPGhttp://www.italgi.it/foto/extrspag1.jpghttp://www.klaroudaseeds.com/wheat-Thur06.jpghttp://images.google.ca/imgres?imgurl=http://www.freshpastamachines.co.uk/images/lillo_dies.jpg&imgrefurl=http://www.freshpastamachines.co.uk/lillo_due_pasta_machine.html&usg=__zGyw76D9SF_rMXa9AoGFgLEITJg=&h=302&w=320&sz=33&hl=en&start=47&itbs=1&tbnid=YToJZz90WcMP6M:&tbnh=111&tbnw=118&prev=/images%3Fq%3Dpasta%2Bextruder%26start%3D36%26hl%3Den%26client%3Dfirefox-a%26sa%3DN%26rls%3Dorg.mozilla:en-GB:official%26gbv%3D2%26ndsp%3D18%26tbs%3Disch:1

- 34. Скачать презентанцию

Preview

Слайды и текст этой презентации

Слайд 5Inputs: Ingredients

Optional:

Eggs

Spinach, tomato puree, chilli, mushrooms for flavour

Substitutes:

Rice, corn,

spelt, kamut for semolina flour

Whole grain, non-grain, or soy-bean flour

for semolina to make it more nutritiousСлайд 6Selection of Semolina

Semolina preferential to other flours for its

Particle size

High

protein content of 13-14% dwb

Makes a less sticky dough during

processing for easier extrusionСлайд 8Combining ingredients: Pre-mixing

Ingredients flows into mixer is regulated by a

volumetric or gravimetric doser

0.180mm mesh sieve sifts the flour to

acquire a homogeneous doughThe flour and water is sent through a high pressure pre-mixer to hydrate the mixture

Слайд 9Combining ingredients: Mixing

Bubbles are removed by a conventional dual shaft

mixer to prevent a weak and pale pasta from forming

Warm

water (45-60°C) is added to bring the moisture content of the dough to 28-32%Spaghetti requires 16-18 minutes in the mixing chamber

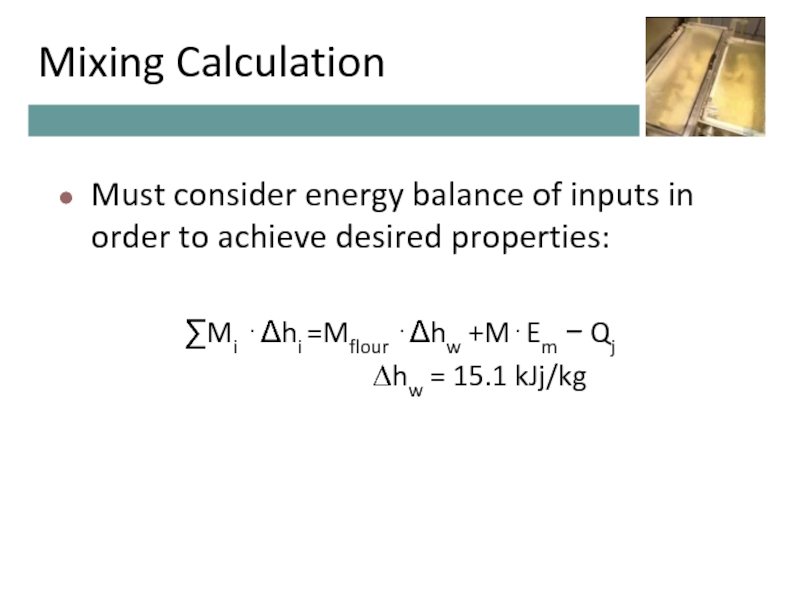

Слайд 10Mixing Calculation

Must consider energy balance of inputs in order

to achieve desired properties:

∑Mi ⋅Δhi =Mflour ⋅Δhw +M⋅Em − Qj

∆hw

= 15.1 kJj/kg Слайд 11Combining ingredients: Extrusion

Gluten matrix develops, assuming dough was sufficiently hydrated

Слайд 13Extrusion

Hydrated semolina mixture drops directly onto the extrusion screw

Screw brings

mixture to extrusion barrel, where it is compacted

Pressure increase from

to 2 MPa to form a compact doughScrew continues to move dough along to extension plate

Слайд 14Extrusion: Challenges yet

Difficult to form uniformly kneaded dough

Solution: apply a

kneading plate

Friction between the walls, barrel, and screw increases the

temperature of doughTremove = (TFrictional + TExtrusion screw)°C – 45°C

(Specific Mechanical Energy) SME =

Cp = 1.44 + 2.74Xw

Ideal temperature: 45 - 50°C

50°C impedes gluten matrix formation

Too cool will yield a dough with undesirable viscosity

Слайд 15Extrusion

Long pasta, like spaghetti are allowed a brief rest before

entering the die in the extension tube

The pasta will be

fully developed by the time taken to reach the end of the extension tubeСлайд 16Extrusion

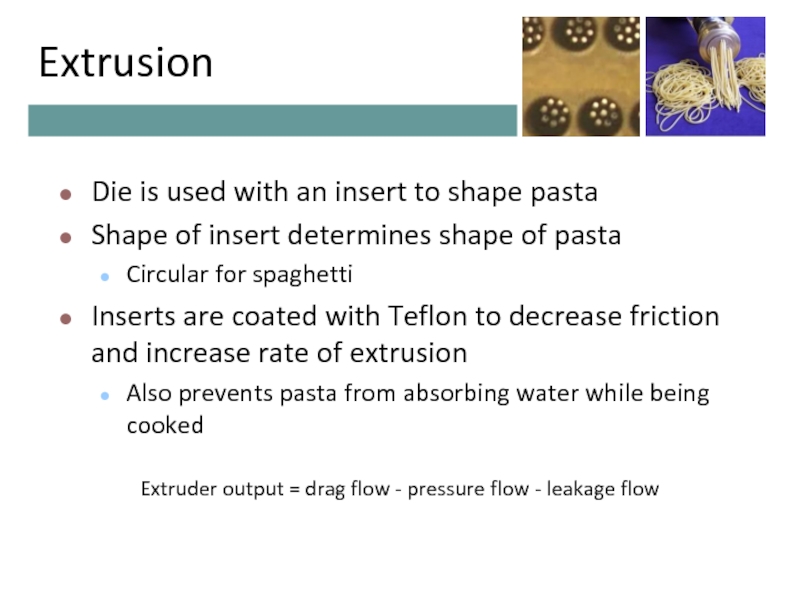

Die is used with an insert to shape pasta

Shape

of insert determines shape of pasta

Circular for spaghetti

Inserts are

coated with Teflon to decrease friction and increase rate of extrusionAlso prevents pasta from absorbing water while being cooked

Extruder output = drag flow - pressure flow - leakage flow

Слайд 17Extrusion

Long pastas are left to stand on a spreader

which cuts them into uniform lengths

Trims result from uneven flow

out from the dieAre collected and brought back to mixer via trim return system

Pastas are then attached to sticks are transfer to dryer

Слайд 18Drying

Purpose: to reduce moisture content to 12% to extend shelf

life

Limits bacterial growth

To determine the amount of water to be

evaporated: MCwb % =

Слайд 19Drying

Four factors involved:

Humidity

Temperature

Time exposure to heat

Air flow

Air flow and time

exposure affects humidity and temperature

Слайд 20Drying: Air flow

Direct contact between air and the pasta enables

the most efficient method of drying due to the greater

surface areaСлайд 21Drying: Humidity

Wet hot air (40-70% w/w)

Prevent product from

cracking at high temperatures

Слайд 22Drying: Exposure Time

High temperatures requires shorter exposure time

Rapid drying

may form cracks in the dough and result in a

brittle the final productLow temperatures requires longer exposure time

Moulds development, especially on the inner parts

Слайд 23Drying: Temperature

Needs to be regulated because

Too high: damage

product and destroy nutrients

Too low: expensive and inefficient

Ranges from 32-110°C

Spaghetti

Pre-dried with gradual increase 30-56°C

Dried by gradual increasing from 56-72°C

Слайд 24Drying: Temperature Regulations

Short pastas are regulated by:

Being on a shaking

pre-dryer to decrease time exposure to high temperature in drier

Long

pastas are regulated by:Pre-dried with blast of air for 30-60 minutes

Dried at 55-82°C

Cooled in a cooling chamber by indirect water contact at 28-32°C for 1.5 hours

Слайд 25Use of Ultra High Temperature

Application of Ultra-High Temperature

May cause non-enzymatic

browning

May result in lysine and vitamins losses

Shortens drying time of

spaghetti from 12 hours to 4.5 hoursResult in product with better cooking properties

Greater expression of yellow in product

Слайд 27Nutritional and Sensory Quality

Nutritious

Carbohydrates

Protein

Vitamin B

Iron

Folic acid

Not fattening itself

Слайд 28Nutritional and Sensory Quality

Ideal food for diabetics, especially whole grain

products

Slow digestion

Maintains steady glucose levels

Gradual insulin release

Because of the limited

surface area for α-amylaseTight protein structure

Limited porosity

With cooking, swelling of pasta restricted by tight gluten matrix and oligosaccharides

Слайд 29Nutritional and Sensory Quality

Yellowness of pasta determine by

Adding eggs

Adding β-carotene (most times)

β-carotene (vitamin A precursor)

Prevents many diseases

Immune function

Vision

Processing makes this more bioavailable

Слайд 30Nutritional and Sensory Quality

Cooking should not exceed >50°C

Damage gluten matrix

Loss

of lysine, vitamins, furosine

Mixing and extruding under pressure

Decrease beta-carotene oxidation

Water

increase calcium and copper slightlyСлайд 31Summary

Mixing, extruding, and drying are required in pasta processing

Extrusion process

forms gluten network

Useful in forming desirable structure for shaping and

cookingGluten also helps retain nutrients

Слайд 32Summary

Drying creates a moisture gradient

Reduces required drying energy, temperature, and

time

Drying requires attention in order to ensure safety and maintain

nutrientsShelf stable product

Preserve nutrients in gluten matrix