Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

SPE-181928-MS. Well Drilling Process Optimization in the Verkhnechonskoye Oil

Содержание

- 1. SPE-181928-MS. Well Drilling Process Optimization in the Verkhnechonskoye Oil

- 2. Verkhnechonskoye Oil and Gas Condensate Field VCOGCF

- 3. Verkhnechonskoye Oil and Gas Condensate Field Slide

- 4. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay AbaltusovVCOGCF Geological Structure

- 5. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay AbaltusovPay Formations in VCOGCF13001650

- 6. Slide SPE-181928-MS • Well Drilling Process Optimization

- 7. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay AbaltusovProduction Casing Section Drilling

- 8. Slide SPE-181928-MS • Well Drilling Process Optimization

- 9. Slide SPE-181928-MS • Well Drilling Process Optimization

- 10. Slide SPE-181928-MS • Well Drilling Process Optimization

- 11. Slide SPE-181928-MS • Well Drilling Process Optimization

- 12. Slide SPE-181928-MS • Well Drilling Process Optimization

- 13. Slide SPE-181928-MS • Well Drilling Process Optimization

- 14. Slide SPE-181928-MS • Well Drilling Process Optimization

- 15. Slide SPE-181928-MS • Well Drilling Process Optimization

- 16. Slide SPE-181928-MS • Well Drilling Process Optimization

- 17. Acknowledgements / Thank You / QuestionsThe authors

- 18. Скачать презентанцию

Слайды и текст этой презентации

Слайд 1SPE-181928-MS. Well Drilling Process Optimization in the Verkhnechonskoye Oil and Gas

Condensate Field

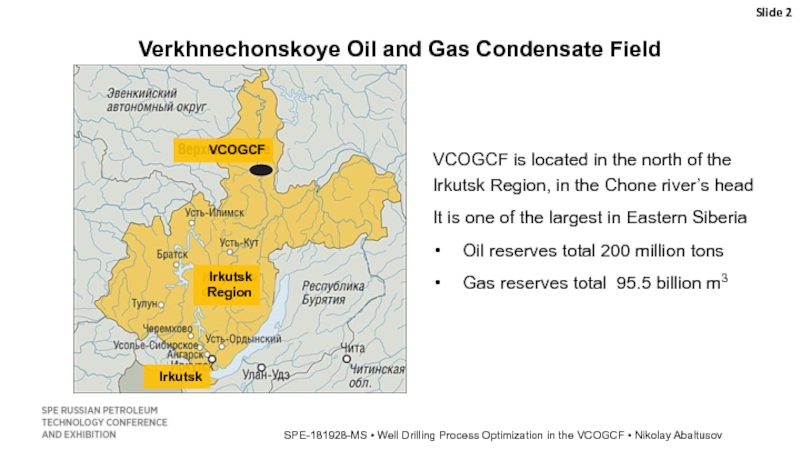

Слайд 2Verkhnechonskoye Oil and Gas Condensate Field

VCOGCF is located in

the north of the Irkutsk Region, in the Chone river’s

headIt is one of the largest in Eastern Siberia

Oil reserves total 200 million tons

Gas reserves total 95.5 billion m3

Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov

VCOGCF

Irkutsk Region

Irkutsk

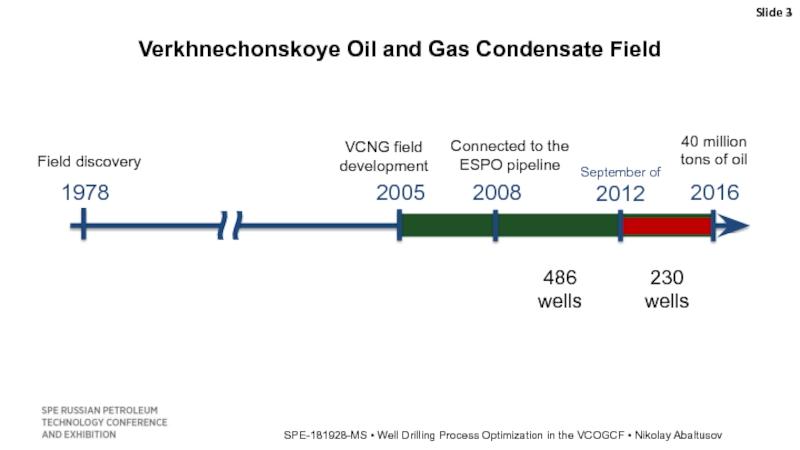

Слайд 3Verkhnechonskoye Oil and Gas Condensate Field

Slide

SPE-181928-MS • Well

Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov

1978

2005

2008

September of

20122016

Field discovery

VCNG field development

Connected to the ESPO pipeline

486

wells

230

wells

40 million

tons of oil

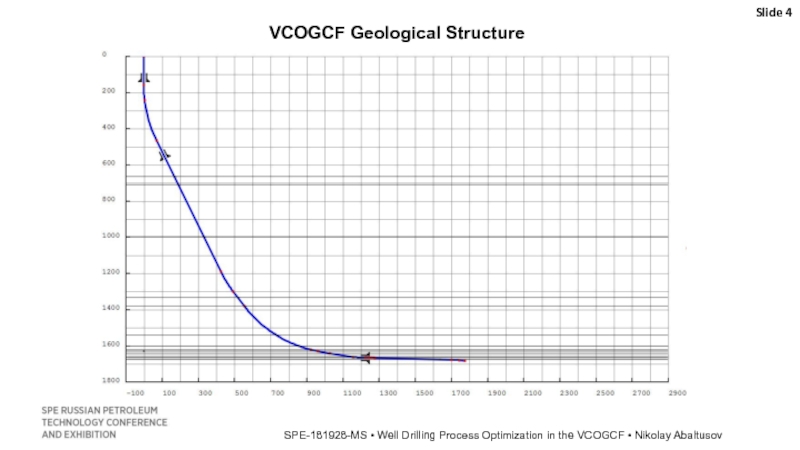

Слайд 4Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

VCOGCF Geological Structure

Слайд 5Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Pay Formations in VCOGCF

1300

1650

Слайд 6Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Well Drilling Process Optimization in VCOGCF

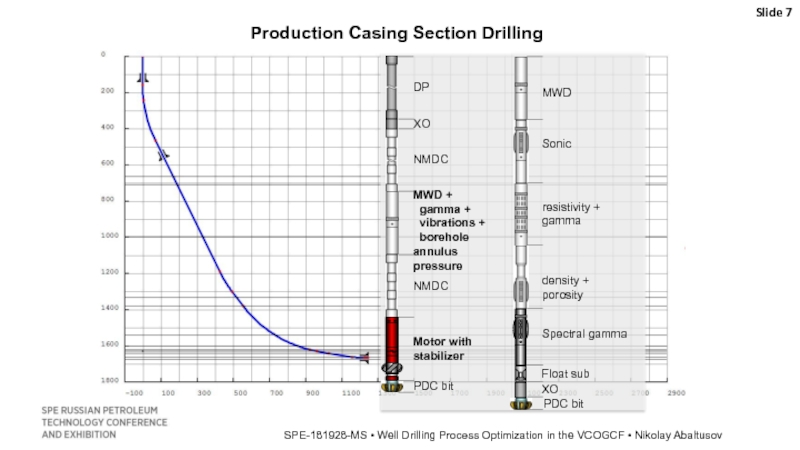

Слайд 7Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Production Casing Section Drilling

Слайд 8Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Experiment #1. Drilling over 2 Runs

Trip out

Bit replacement

Motor

replacementRun 1

Run 2

Middle Moti suite

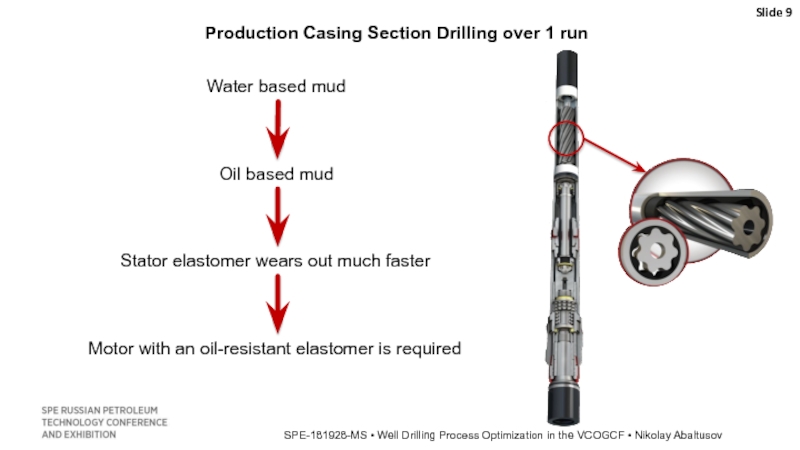

Слайд 9Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Production Casing Section Drilling over 1 run

Motor with

an oil-resistant elastomer is requiredStator elastomer wears out much faster

Water based mud

Oil based mud

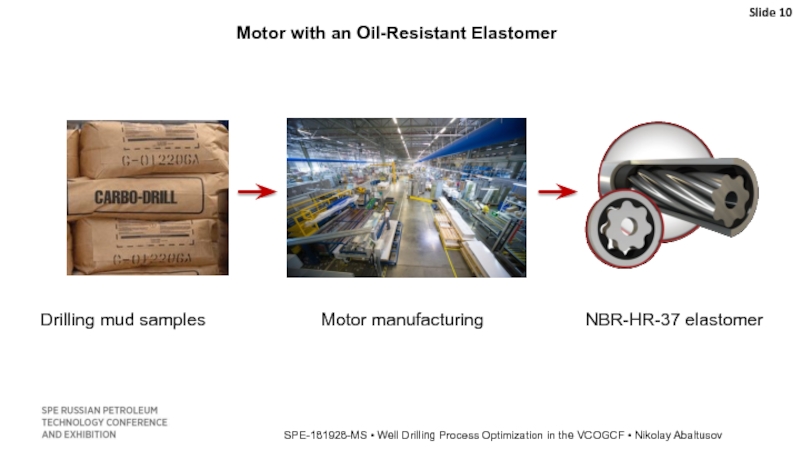

Слайд 10Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Motor with an Oil-Resistant Elastomer

Drilling mud samples

Motor manufacturing

NBR-HR-37

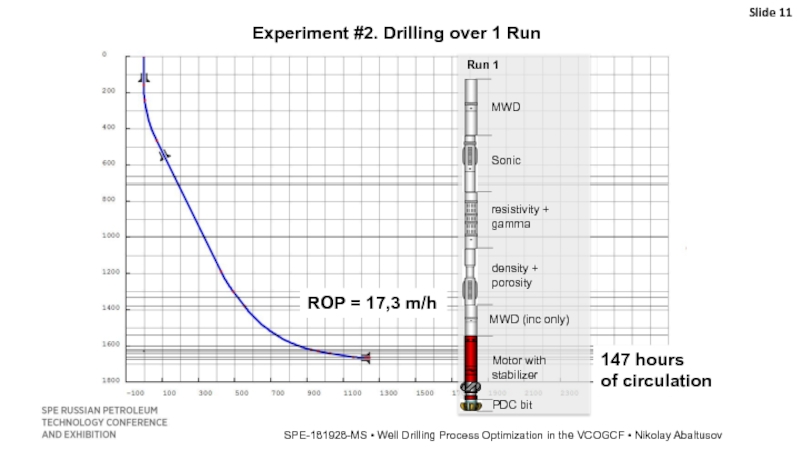

elastomerСлайд 11Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Experiment #2. Drilling over 1 Run

Run 1

ROP =

17,3 m/h147 hours

of circulation

Слайд 12Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Time for Drilling Production Casing Section

Conventional drilling of

production casing sectionDrilling over 2 runs

12-30 h

≈ 45 hours

Drilling over 1 run

depth, m

days

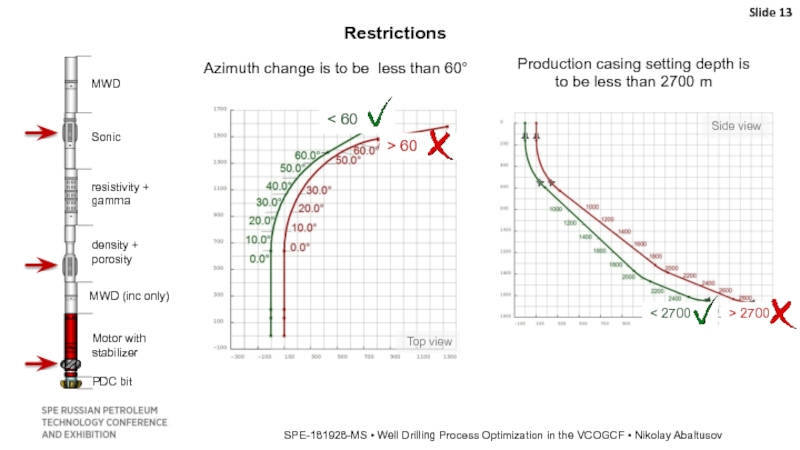

Слайд 13Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Restrictions

Azimuth change is to be less than 60°

Production

casing setting depth is to be less than 2700 mSide view

Top view

< 60

> 60

< 2700

> 2700

Слайд 14Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

The Results of Production Casing Section Drilling Optimization

LWD suite is included in BHA

Production casing section is drilled per one run

The bit design is optimized

An optimal size of the motor stabilizer is selected

Water based mud is replaced by oil based mud

Oil resistant elastomer is selected based on drilling fluid sampling

MWD pulser is adjusted based on defined borehole conditions

Data transmission speed increase

ROP increase

An individual approach to each well

Preliminary calculations of hydraulics, WOB, tensions and torques

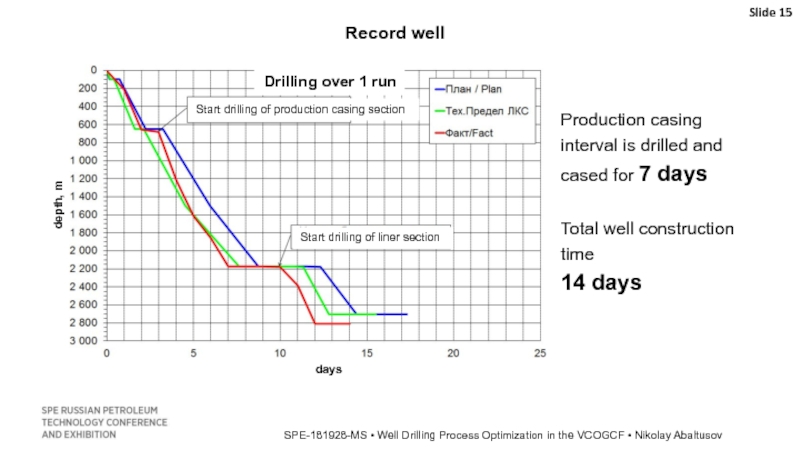

Слайд 15Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

Record well

Production casing interval is drilled and cased

for 7 daysTotal well construction time 14 days

Слайд 16Slide

SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

• Nikolay Abaltusov

The Results of Production Casing Section Drilling Optimization

8 wells drilled with Drilling optimization

250 hrs of total well-construction time saving

15 000 000 RUB – Value to Client

Слайд 17Acknowledgements / Thank You / Questions

The authors express thanks to

the management groups of PAO “VCNG” (PAO “NK Rosneft”) and

Weatherford companies for the permission to publish and submit the results of this paper.We also express thanks to the drilling crew and the service specialists who were involved in the well drilling and were gathering the field data for analysis.

Slide