Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Extraction Fundamentals: Impact on Extractor Design & Operation

Содержание

- 1. Extraction Fundamentals: Impact on Extractor Design & Operation

- 2. Oilseed microstructure

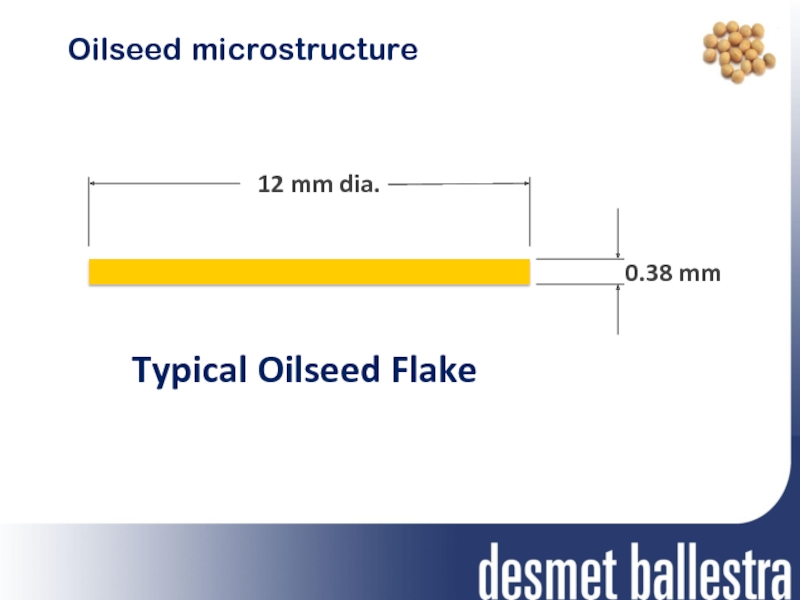

- 3. Oilseed microstructure0.38 mm12 mm dia.Typical Oilseed Flake

- 4. Oilseed microstructureTypical Oilseed FlakeLets zoom in fora closer look

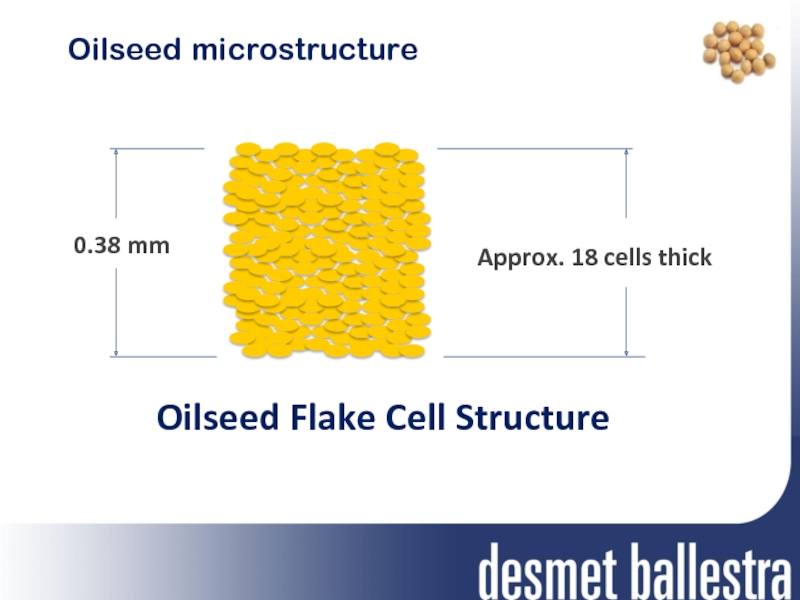

- 5. Oilseed microstructureOilseed Flake Cell Structure0.38 mmApprox. 18 cells thick

- 6. Oilseed microstructureOilseed Flake Cell Structure0.38 mmLets zoom in further to view a single cell

- 7. Oilseed microstructureProtein BodiesCell WallCarbohydrates, Ash, etc.Oil BodiesTypical Oilseed Cell

- 8. Oilseed microstructureActual Soybean Cellvia electron microscopeProtein BodiesCell WallCarbohydrates, Ash, etc.Oil Bodies

- 9. Solvent Extraction Process

- 10. Solvent Extraction ProcessThe extraction process starts when

- 11. Solvent Extraction ProcessThe extraction process gets underway

- 12. Solvent Extraction ProcessAfter the solvent diffuses inward

- 13. Solvent Extraction ProcessPressure builds within the cell, and a portion of the miscella diffuses outward.

- 14. Solvent Extraction ProcessMiscella diffusing out of the cells diffuses into neighboring cells.

- 15. Solvent Extraction ProcessThe process of inward diffusion,

- 16. Solvent Extraction Process… and back out again

- 17. Solvent Extraction ProcessThe extraction process is complete

- 18. Solvent Extraction Parameters

- 19. Solvent Extraction Parameters CONTACT TIME FLAKE THICKNESS

- 20. Solvent Extraction ParametersThe extraction process can take

- 21. Solvent Extraction Parameters60% OPEN AREA30% OPEN AREAVAPOR ESCAPESPERCOLATIONIMMERSIONPOORCONTACTIDEALOPERATION WITH 100% CONTACT TIME“FLOODING”GOODCONTACT

- 22. Solvent Extraction ParametersWith 0.38 mm thick flakes

- 23. Solvent Extraction Parameters20% thinner flakes (0.38 mm

- 24. Solvent Extraction Parameters20% thinner flakes (0.38 mm

- 25. Solvent Extraction ParametersThe higher the extractor operating

- 26. Solvent Extraction ParametersCommercial hexane boiling range is

- 27. Solvent Extraction ParametersMiscella flux rate is the

- 28. Solvent Extraction ParametersThe orientation of miscella collection

- 29. Solvent Extraction ParametersSAMPLE MISCELLA DRAIN ANGLE CALCULATIONSeed

- 30. Solvent Extraction ParametersPresent Reflex Extractor Miscella staging for normal quality flakes

- 31. Solvent Extraction Parameterslow miscella flux rates from

- 32. Solvent Extraction ParametersMinimizing surface moisture

- 33. Solvent Extraction ParametersThe volume of the cells

- 34. Solvent Extraction ParametersAdequate dripping time

- 35. Solvent Extraction ParametersFor an extractor to achieve

- 36. Solvent Extraction ParametersIn theory, if a countercurrent

- 37. Solvent Extraction Parameters CONTACT TIME FLAKE THICKNESS

- 38. Thank you!Tim KemperGlobal Technical Director,Solvent ExtractionCRUSHING SHORTCOURSEKiev, UkraineApril 2013

- 39. Скачать презентанцию

Слайды и текст этой презентации

Слайд 1Extraction Fundamentals:

Impact on Extractor Design & Operation

CRUSHING SHORTCOURSE

Kiev, Ukraine

5 April

2013

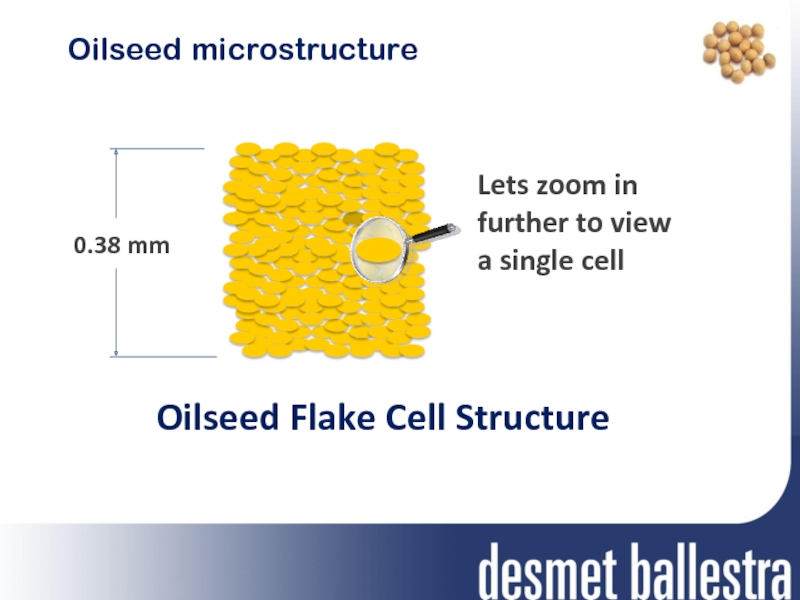

Слайд 6Oilseed microstructure

Oilseed Flake Cell Structure

0.38 mm

Lets zoom in

further to

view

a single cell

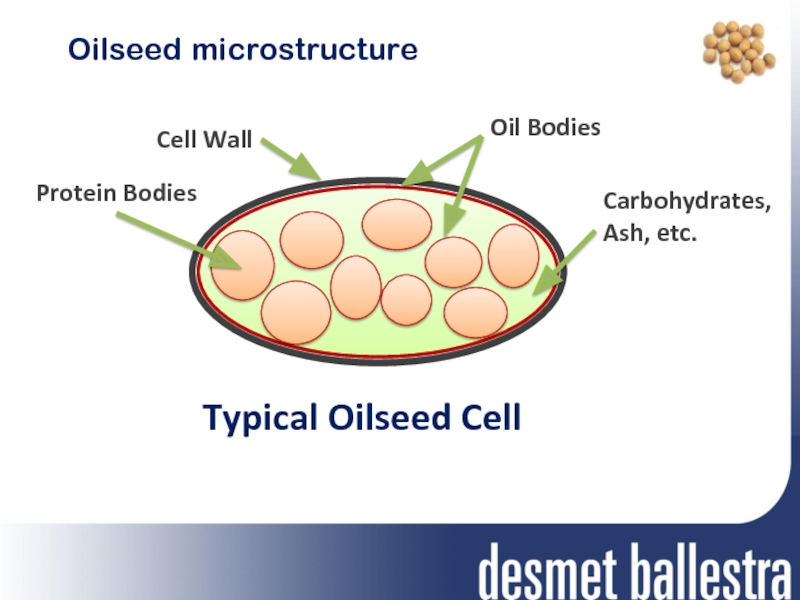

Слайд 7Oilseed microstructure

Protein Bodies

Cell Wall

Carbohydrates,

Ash, etc.

Oil Bodies

Typical Oilseed Cell

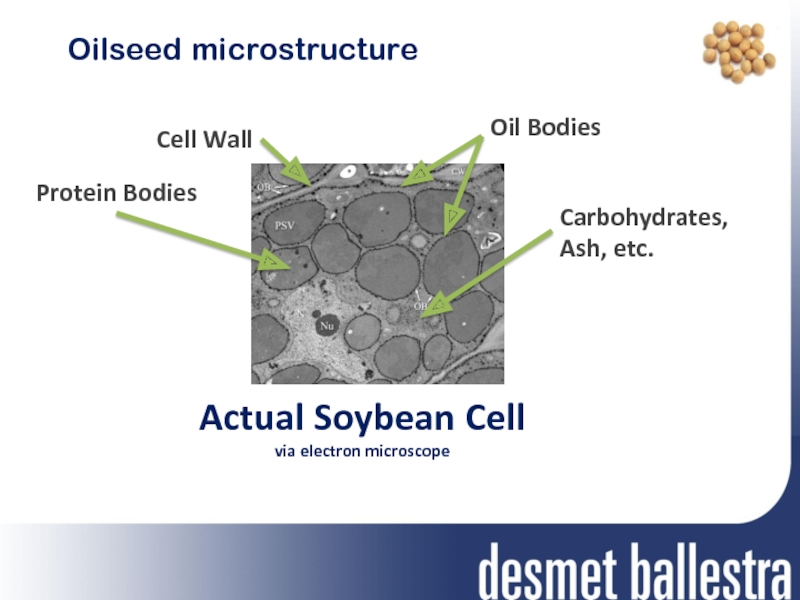

Слайд 8Oilseed microstructure

Actual Soybean Cell

via electron microscope

Protein Bodies

Cell Wall

Carbohydrates,

Ash, etc.

Oil

Bodies

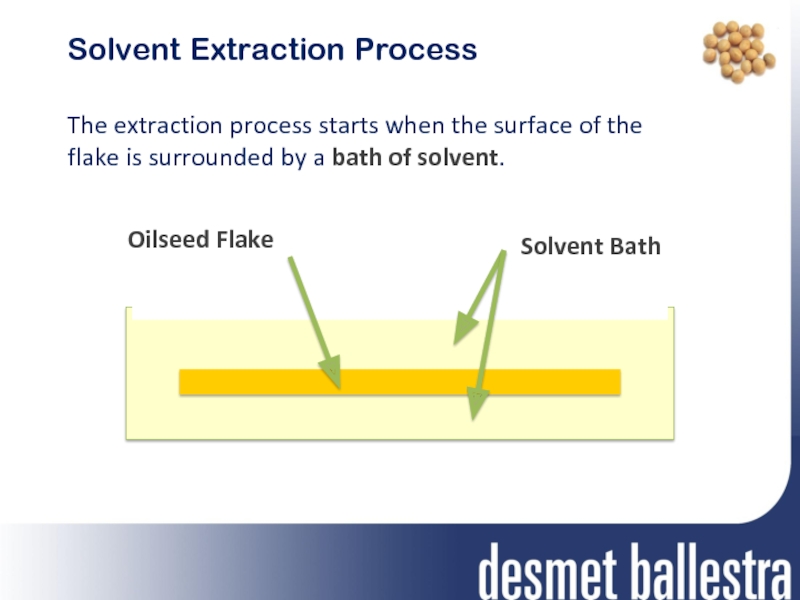

Слайд 10Solvent Extraction Process

The extraction process starts when the surface of

the flake is surrounded by a bath of solvent.

Solvent Bath

Oilseed

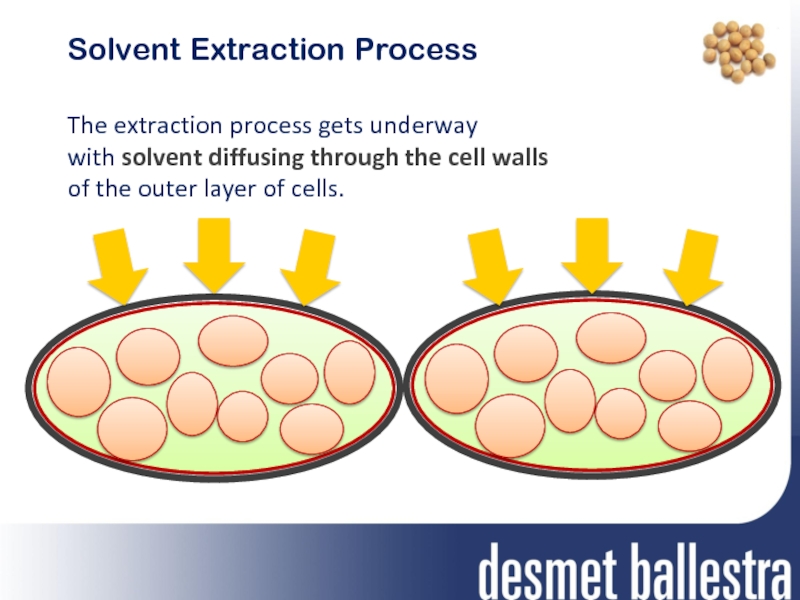

FlakeСлайд 11Solvent Extraction Process

The extraction process gets underway

with solvent diffusing

through the cell walls

of the outer layer of cells.

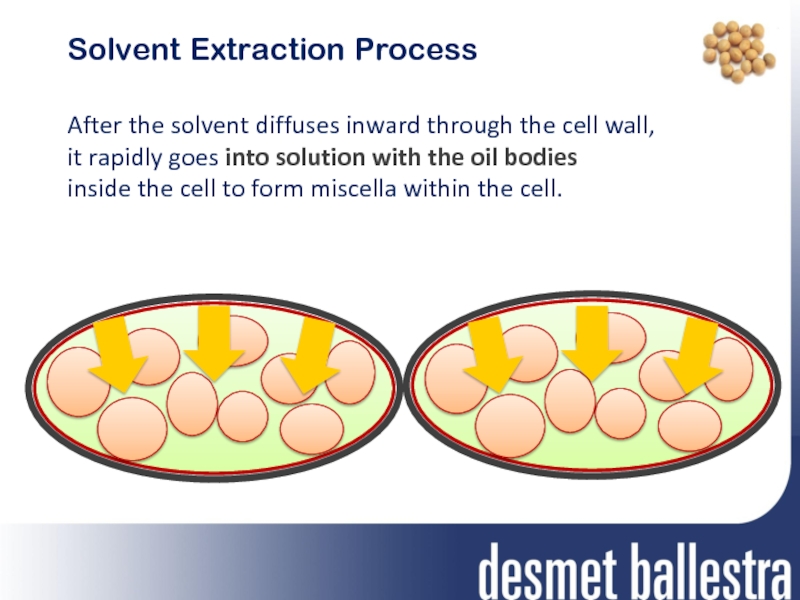

Слайд 12Solvent Extraction Process

After the solvent diffuses inward through the cell

wall, it rapidly goes into solution with the oil bodies

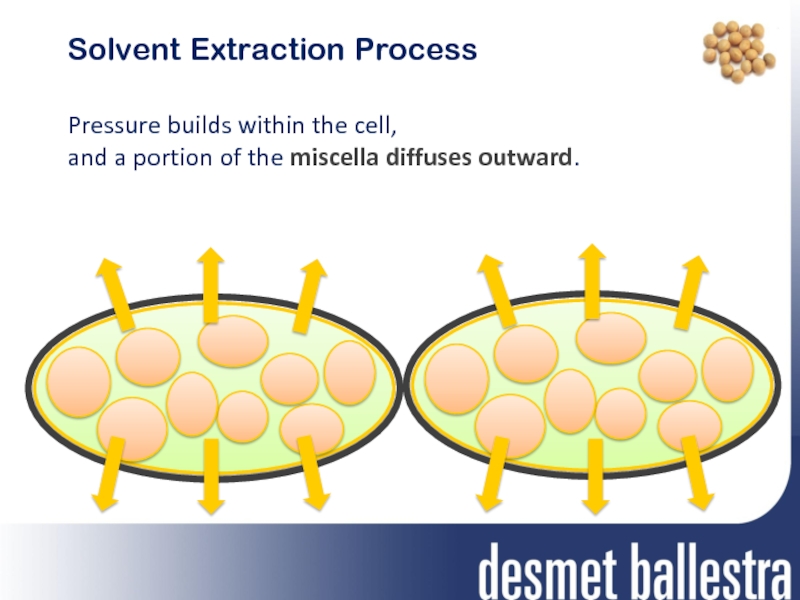

inside the cell to form miscella within the cell.Слайд 13Solvent Extraction Process

Pressure builds within the cell,

and a portion

of the miscella diffuses outward.

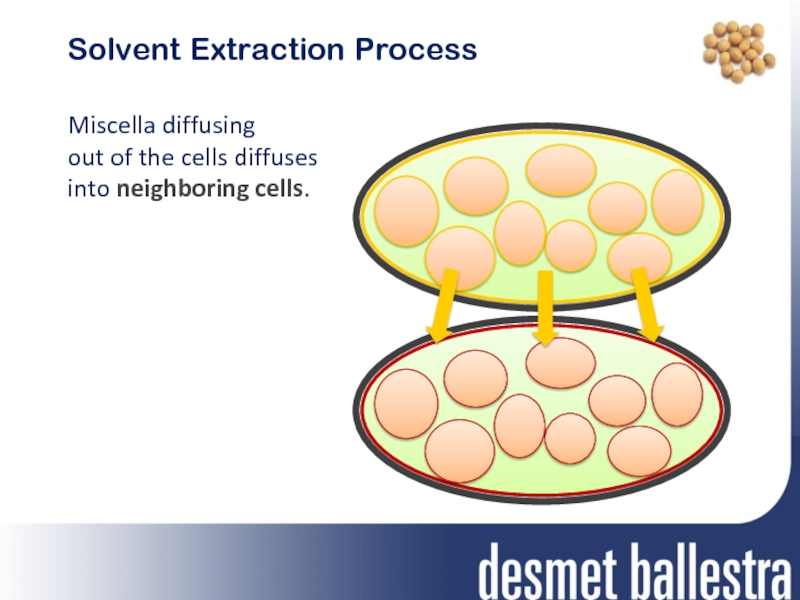

Слайд 14Solvent Extraction Process

Miscella diffusing

out of the cells diffuses

into

neighboring cells.

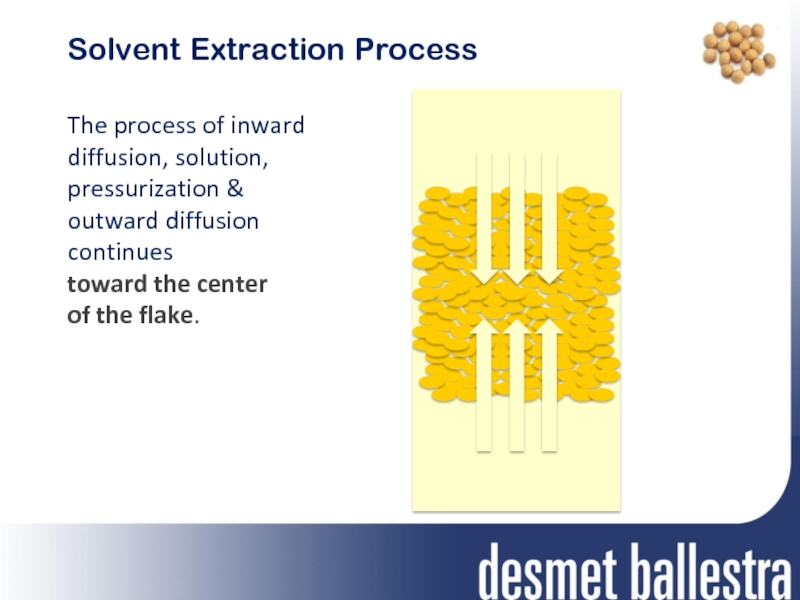

Слайд 15Solvent Extraction Process

The process of inward diffusion, solution, pressurization &

outward diffusion continues

toward the center

of the flake.

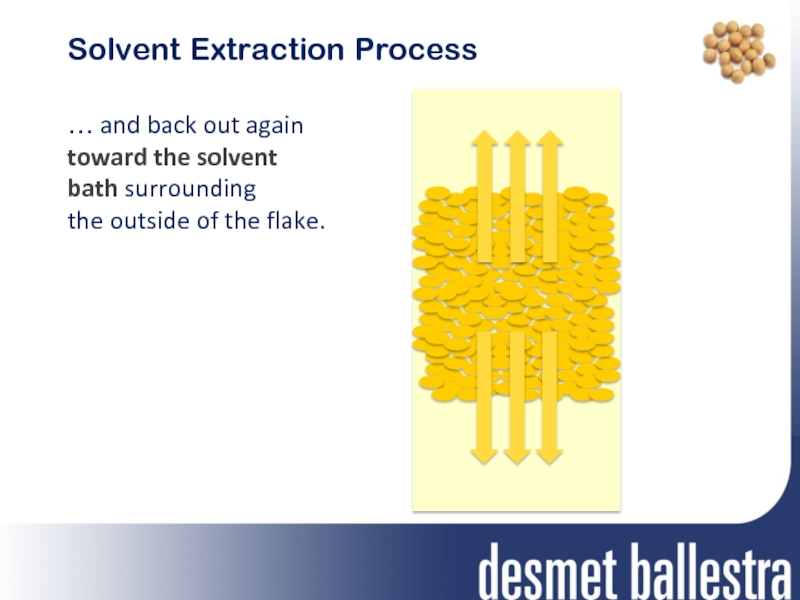

Слайд 16Solvent Extraction Process

… and back out again toward the solvent

bath surrounding

the outside of the flake.

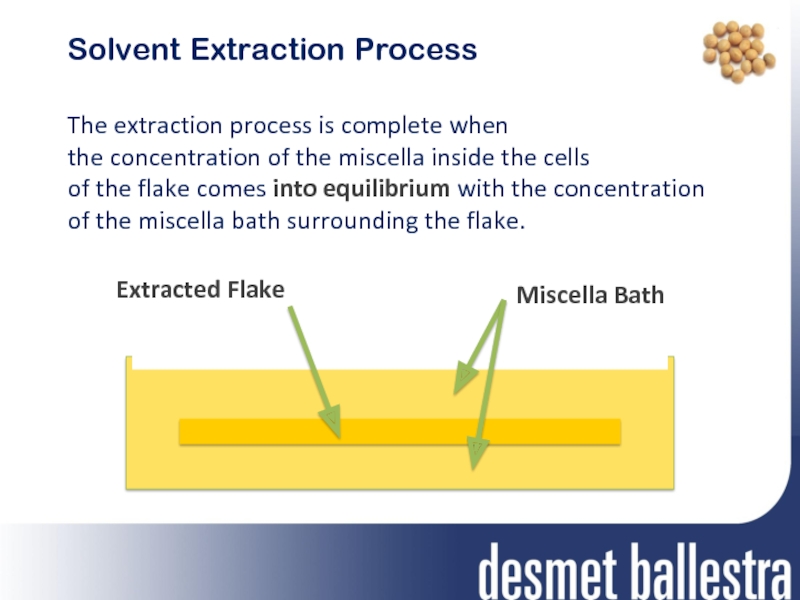

Слайд 17Solvent Extraction Process

The extraction process is complete when

the concentration

of the miscella inside the cells of the flake comes

into equilibrium with the concentration of the miscella bath surrounding the flake.Miscella Bath

Extracted Flake

Слайд 19Solvent Extraction Parameters

CONTACT TIME

FLAKE THICKNESS

TEMPERATURE

MISCELLA FLUX

RATE

SOLVENT RETENTION

NUMBER OF STAGES

Six

Extraction

Parameters

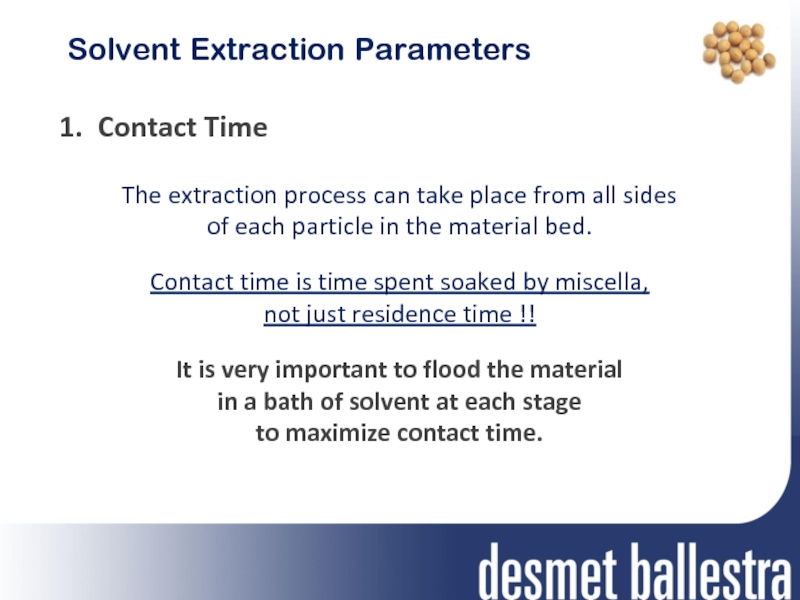

Слайд 20Solvent Extraction Parameters

The extraction process can take place from all

sides

of each particle in the material bed.

Contact time is

time spent soaked by miscella,

not just residence time !! It is very important to flood the material in a bath of solvent at each stage to maximize contact time.

Contact Time

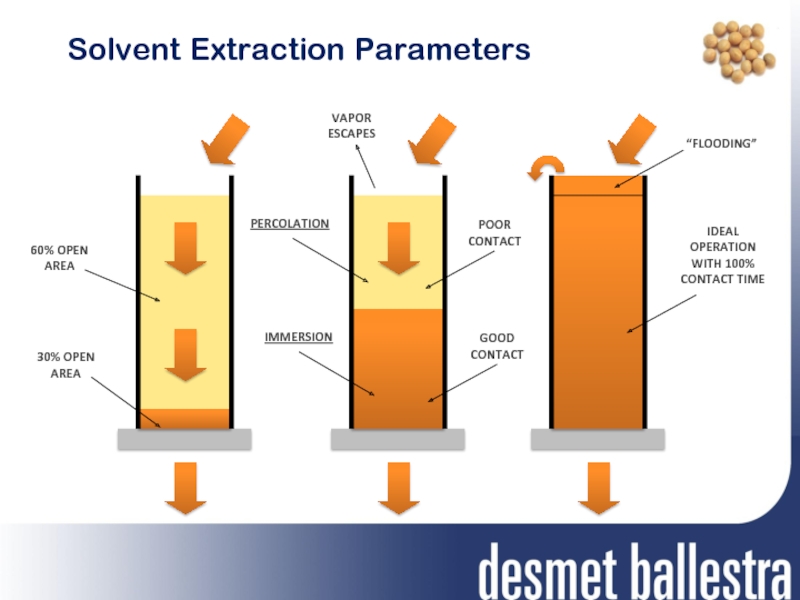

Слайд 21Solvent Extraction Parameters

60% OPEN

AREA

30% OPEN

AREA

VAPOR

ESCAPES

PERCOLATION

IMMERSION

POOR

CONTACT

IDEAL

OPERATION

WITH 100%

CONTACT TIME

“FLOODING”

GOOD

CONTACT

Слайд 22Solvent Extraction Parameters

With 0.38 mm thick flakes and 60°C,

it

takes 5 minutes of contact time in each stage to

reach equilibrium.If contact time is insufficient in any given extraction stage, then that stage will not reach equilibrium.

Residual oil in meal will increase !!

Contact Time

Слайд 23Solvent Extraction Parameters

20% thinner flakes (0.38 mm 0.30 mm)

decrease the time required for the miscella in the cells

to reach equilibrium with the surrounding miscella by over 20%, reducing contact time needed from 5 minutes to under 4 minutes per stage.20% thinner flakes require about 1.5 kwh per ton additional energy to create, adding significantly to operational costs.

Flake Thickness

Слайд 24Solvent Extraction Parameters

20% thinner flakes (0.38 mm 0.30 mm)

decrease the miscella flux rate (downward miscella velocity) through the

flake bed by 40%, significantly moving back the location where the miscella exits the material bed through the screen floor.In summary, 0.38 mm thick flakes reach equilibrium in 5 minutes of contact time, and minimize flaking operational costs. The extractor should be sized large enough to accommodate 0.38 mm thick flakes.

Flake Thickness

Слайд 25Solvent Extraction Parameters

The higher the extractor operating temperature,

the faster

the miscella diffuses through cell walls,

and the faster the cells come into equilibrium with the surrounding miscella.At the azeotropic temperature of 61-62°C, surface moisture and solvent evaporate off together. Surface moisture evaporating off also helps improve extraction efficiency.

Temperature

Слайд 26Solvent Extraction Parameters

Commercial hexane boiling range is 67-69°C,

and if

the extractor is operated too close to the boiling range,

excessive evaporation and over-pressurization will take place, losing significant solvent.When balancing extraction efficiency with safety and environmental concerns,

the extractor should ideally be operated at or just under the azeotropic temperature at 60-62°C.

Temperature

Слайд 27Solvent Extraction Parameters

Miscella flux rate is the rate which miscella

descends down through the material bed. How the material is

prepared has a big impact on the miscella flux rate:Good quality expanded soybean pellets

49 m3/h/m2 or 1.71 m/min down through expandates

Good quality 0.38 mm soybean flakes

19.5 m3/h/m2 or 0.58 m/min down through flakes

Good quality 0.30 mm soybean flakes

12 m3/h/m2 or 0.34/min down through flakes

Miscella Flux rate

Слайд 28Solvent Extraction Parameters

The orientation of miscella collection hoppers under

the

material bed is designed to be in the

ideal location to catch the proper miscella stage.If miscella flux rate reduces significantly, the miscella will descend to a later miscella collection hopper and contaminate a weaker miscella stage, causing residual oil to increase.

Miscella Flux rate

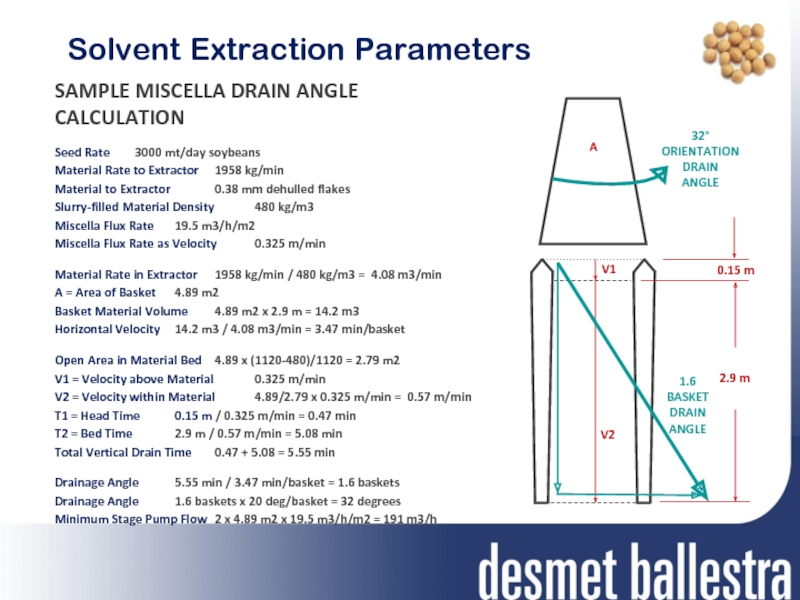

Слайд 29Solvent Extraction Parameters

SAMPLE MISCELLA DRAIN ANGLE CALCULATION

Seed Rate 3000 mt/day

soybeans

Material Rate to Extractor 1958 kg/min

Material to Extractor 0.38

mm dehulled flakesSlurry-filled Material Density 480 kg/m3

Miscella Flux Rate 19.5 m3/h/m2

Miscella Flux Rate as Velocity 0.325 m/min

Material Rate in Extractor 1958 kg/min / 480 kg/m3 = 4.08 m3/min

A = Area of Basket 4.89 m2

Basket Material Volume 4.89 m2 x 2.9 m = 14.2 m3

Horizontal Velocity 14.2 m3 / 4.08 m3/min = 3.47 min/basket

Open Area in Material Bed 4.89 x (1120-480)/1120 = 2.79 m2

V1 = Velocity above Material 0.325 m/min

V2 = Velocity within Material 4.89/2.79 x 0.325 m/min = 0.57 m/min

T1 = Head Time 0.15 m / 0.325 m/min = 0.47 min

T2 = Bed Time 2.9 m / 0.57 m/min = 5.08 min

Total Vertical Drain Time 0.47 + 5.08 = 5.55 min

Drainage Angle 5.55 min / 3.47 min/basket = 1.6 baskets

Drainage Angle 1.6 baskets x 20 deg/basket = 32 degrees

Minimum Stage Pump Flow 2 x 4.89 m2 x 19.5 m3/h/m2 = 191 m3/h

0.15 m

2.9 m

V1

V2

A

1.6

BASKET

DRAIN

ANGLE

32°

ORIENTATION

DRAIN

ANGLE

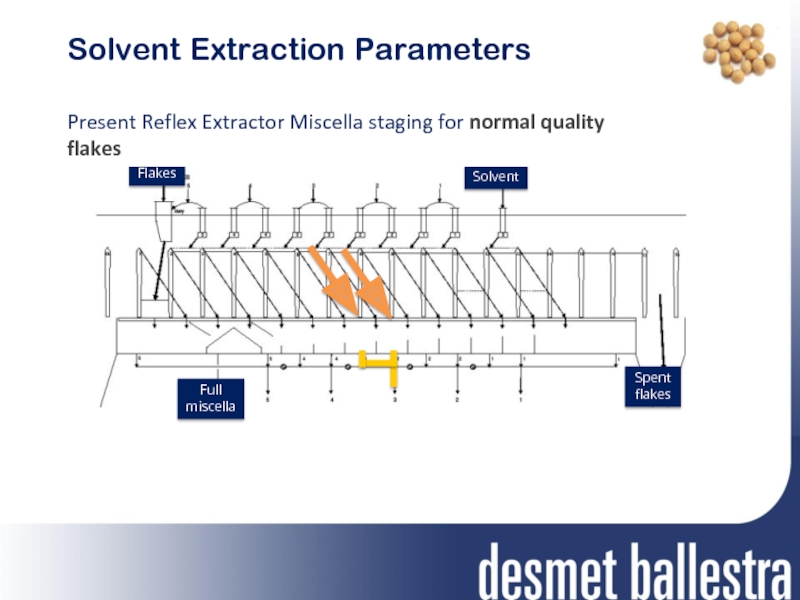

Слайд 30Solvent Extraction Parameters

Present Reflex Extractor Miscella staging for normal quality

flakes

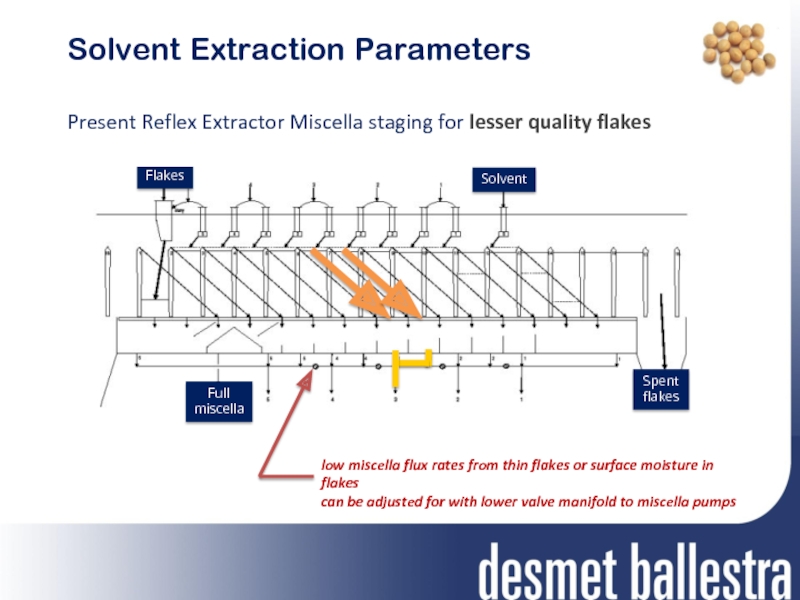

Слайд 31Solvent Extraction Parameters

low miscella flux rates from thin flakes or

surface moisture in flakes

can be adjusted for with lower valve

manifold to miscella pumpsFlakes

Solvent

Full

miscella

Spent

flakes

Present Reflex Extractor Miscella staging for lesser quality flakes

Слайд 32Solvent Extraction Parameters

Minimizing surface moisture

going to the extractor through good flaking mill aspiration and good expander pellet drying improves the miscella flux rate.

Minimizing fines going to the extractor through more uniform grain drying, adequate tempering time, coarser cracking and proper material handling improves the miscella flux rate.

Miscella Flux rate

Слайд 33Solvent Extraction Parameters

The volume of the cells that was once

oil (18-20%) will fill up with the weakest stage of

miscella (0.5% oil) and be carried to the DT. Additional miscella will also be soaked into the cell, and will also coat the surface of the flake going to the DT, increasing solvent retention to 30%.The lower the solvent retention to the DT, the less oil (0.5% oil with solvent) will be carried along,

thus reducing residual oil in the meal.

Solvent Retention

Слайд 34Solvent Extraction Parameters

Adequate dripping time

in the extractor is the most cost effective means of minimizing solvent retention.

Increasing the percentage of expanded pellets

increases the percentage of ruptured cell walls

to further reduce solvent retention down to 26%. However, expanders also increases upstream

operational costs.

Solvent Retention

Слайд 35Solvent Extraction Parameters

For an extractor to achieve 0.5% oil in

white flakes,

with 30% solvent retention, the last, weakest miscella

concentration can not exceed 0.5% oil. If an extractor had 1 miscella stage, then full miscella would need to be 0.5% oil to achieve 0.5% oil in white flakes. This would require a tremendous fresh hexane

flow and would be cost prohibitive in distillation energy.

Number of stages

Слайд 36Solvent Extraction Parameters

In theory, if a countercurrent extractor reaches complete

equilibrium in 4 miscella stages, it can reach a weakest

miscella concentration under 0.5% with a full miscella concentration of 25% and achieve 0.5% oil in white flakes.In the real world, it is difficult for every miscella stage

to reach complete equilibrium, so extractors need at least 5 stages (one excess). More stages increase safety factor at the expense of higher pump energy and maintenance.

Number of stages