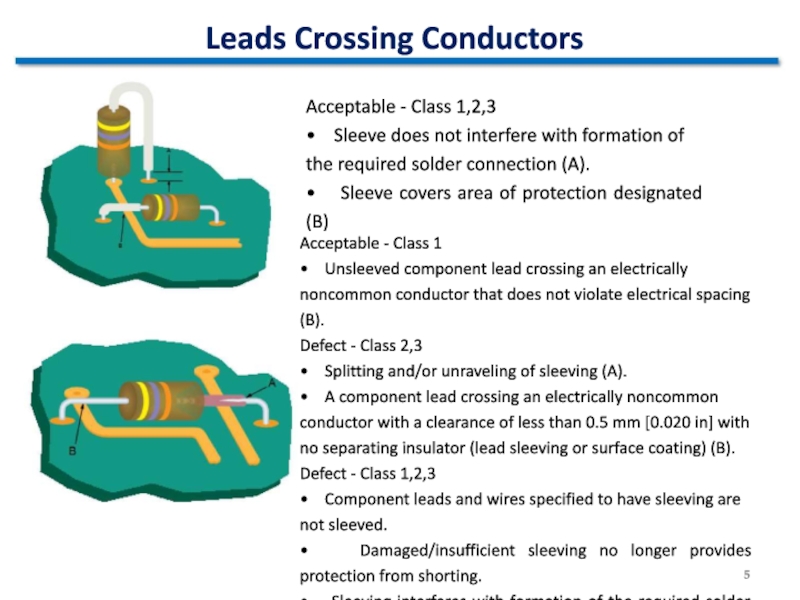

interfere with formation of the required solder connection (A).

•

Sleeve covers area of protection designated (B)Acceptable - Class 1

• Unsleeved component lead crossing an electrically noncommon conductor that does not violate electrical spacing (B).

Defect - Class 2,3

• Splitting and/or unraveling of sleeving (A).

• A component lead crossing an electrically noncommon conductor with a clearance of less than 0.5 mm [0.020 in] with no separating insulator (lead sleeving or surface coating) (B). Defect - Class 1,2,3

• Component leads and wires specified to have sleeving are not sleeved.

• Damaged/insufficient sleeving no longer provides protection from shorting.

• Sleeving interferes with formation of the required solder con nection.

5