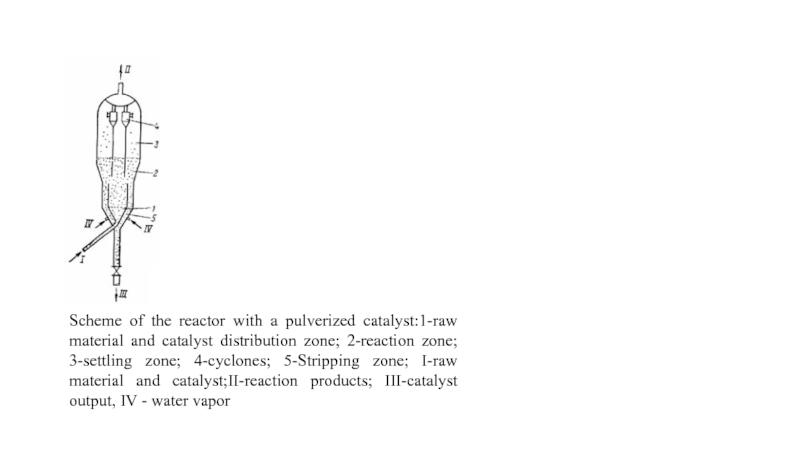

which uses a ball catalyst, are:

possibility of simple regulation within

wide limits of degree of transformation of raw materials and circulation of the catalyst;

intensive mixing in the reactor and regenerator, eliminating local overheating and providing high heat transfer coefficients;

lower energy costs for catalyst transport;

simpler designs of the main devices.

Main features of the process

The disadvantage of cracking in a fluidized bed is that due to the intensive mixing of the raw material in the reactor is mixed with the reaction products and regenerated catalyst in the regenerator with the coked catalyst, i.e. no backflow and more complete regeneration processing of a catalyst.