Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

MAN Diesel PrimeServ Academy Exhaust Valve Design

Содержание

- 1. MAN Diesel PrimeServ Academy Exhaust Valve Design

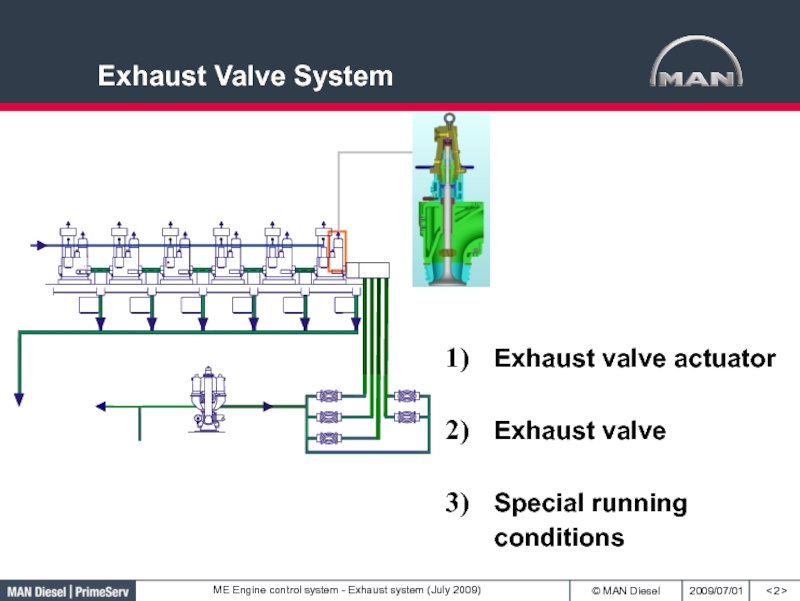

- 2. Exhaust Valve System< >Exhaust valve actuatorExhaust valveSpecial running conditions

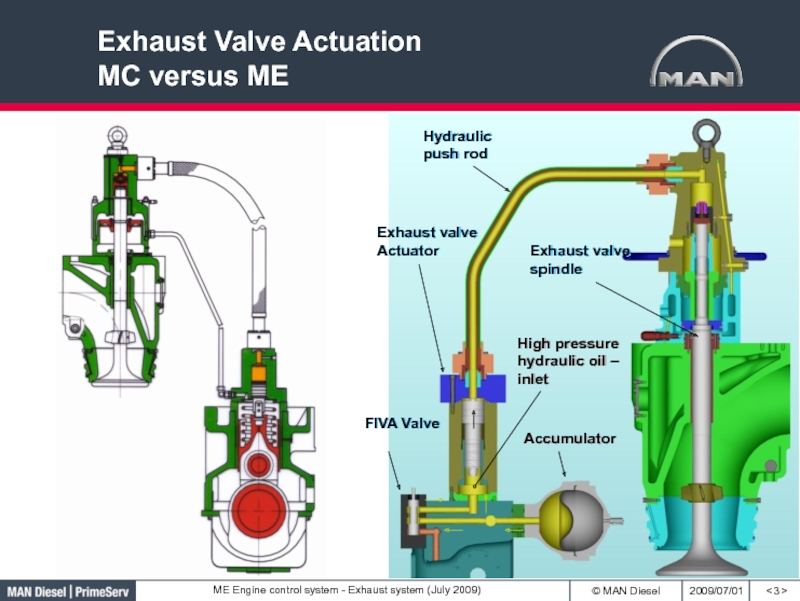

- 3. Exhaust Valve Actuation MC versus ME< >

- 4. Exhaust Valve Pipe Connections< >

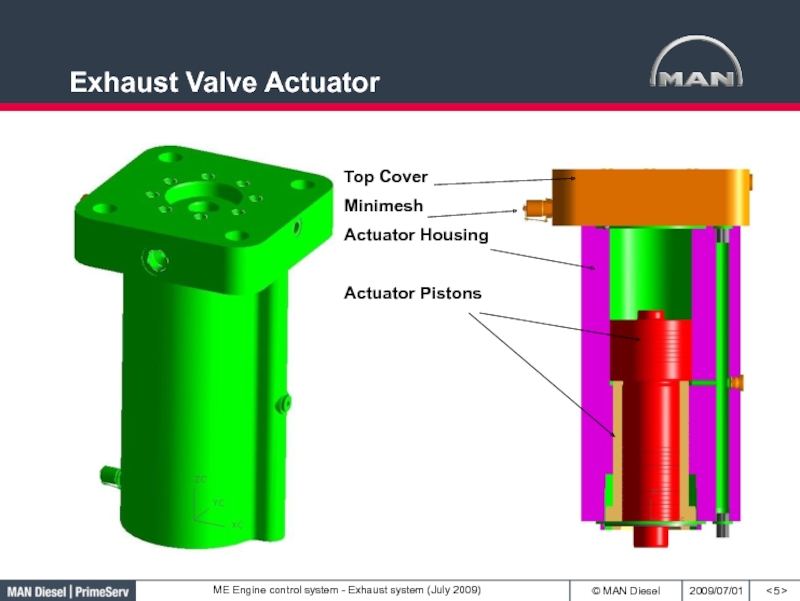

- 5. Exhaust Valve Actuator< >Top CoverMinimeshActuator HousingActuator Pistons

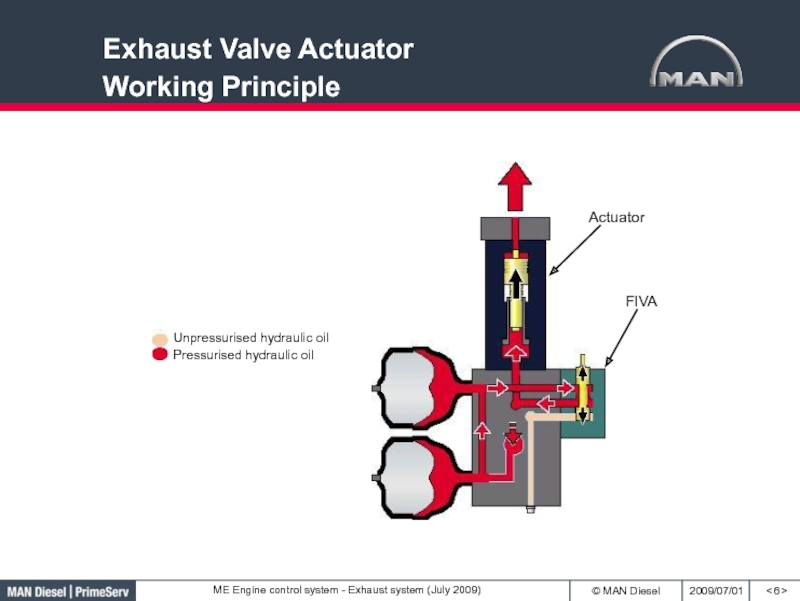

- 6. < >Exhaust Valve Actuator Working Principle

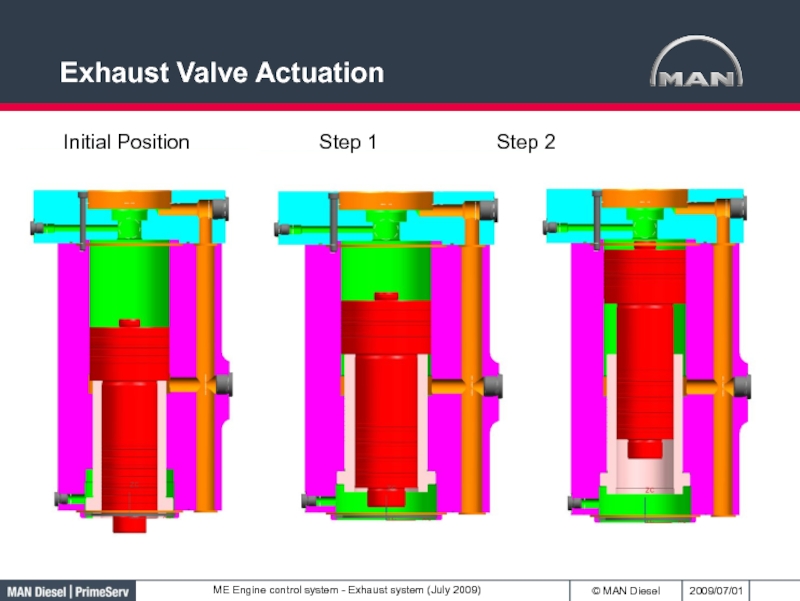

- 7. Exhaust Valve ActuationInitial Position Step 1 Step 2

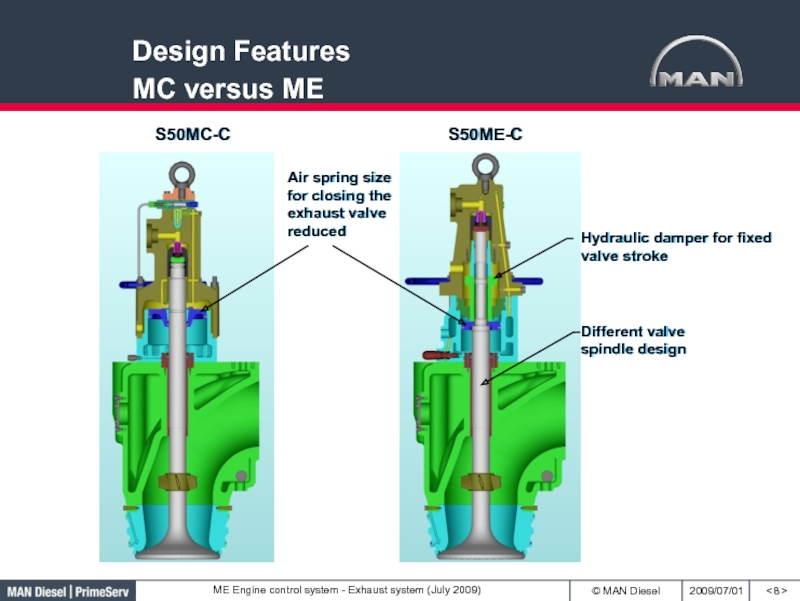

- 8. < >S50MC-CS50ME-CHydraulic damper for fixed valve strokeAir

- 9. < >Self-adjusting damper pistonHydraulic nut/measuring coneOutlet lube

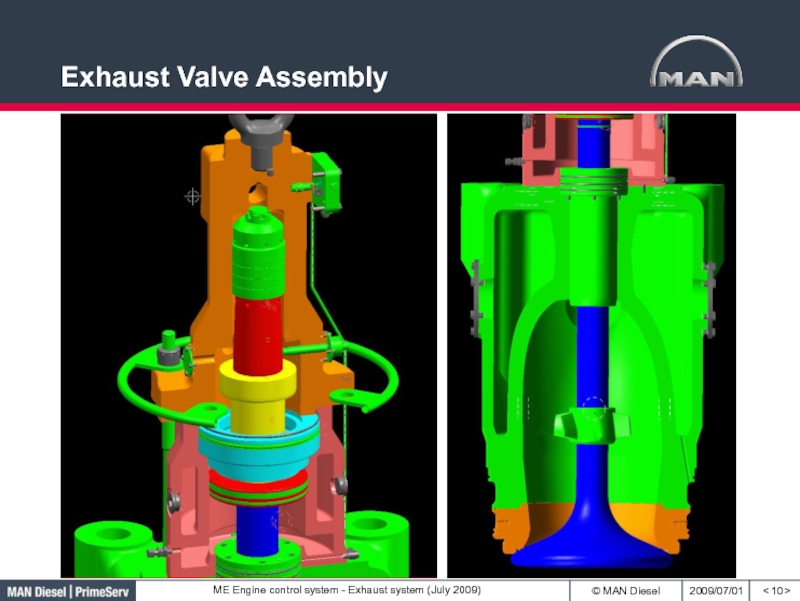

- 10. < >Exhaust Valve Assembly

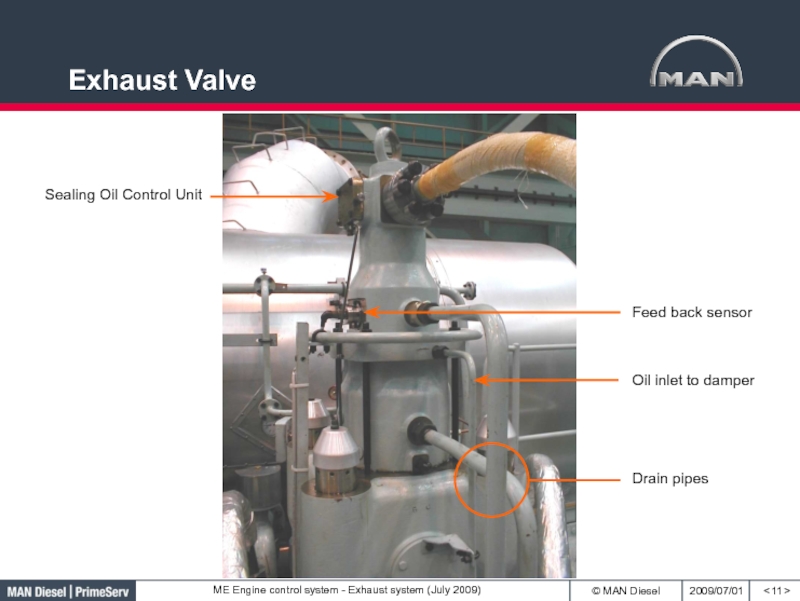

- 11. < >Oil inlet to damperDrain pipesFeed back sensorSealing Oil Control UnitExhaust Valve

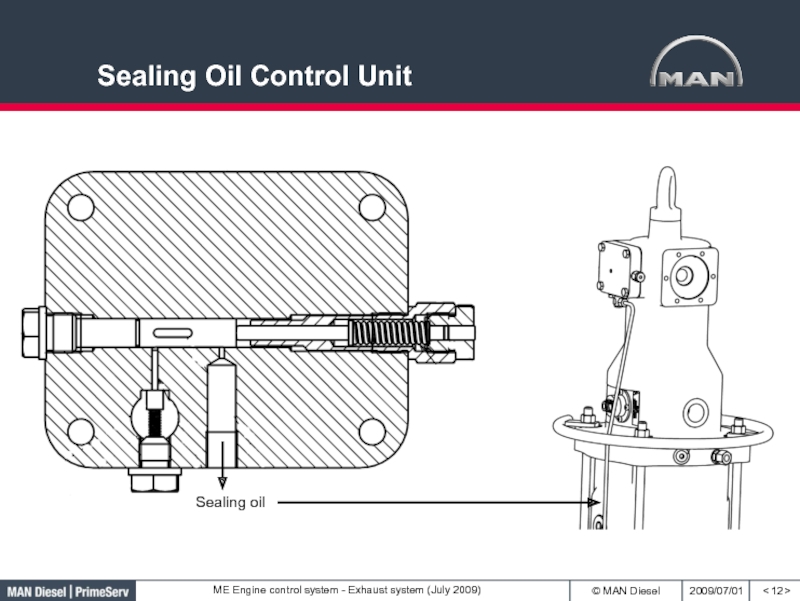

- 12. Sealing Oil Control Unit< >Sealing oil

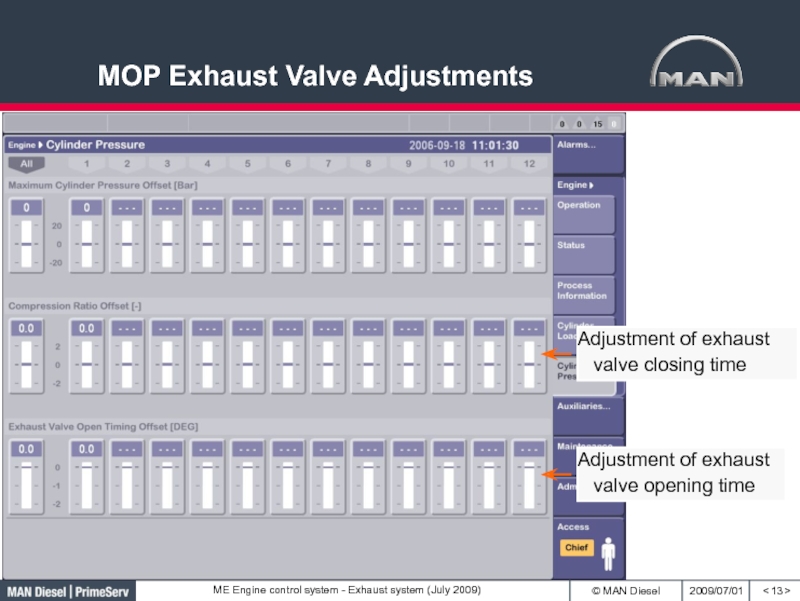

- 13. MOP Exhaust Valve Adjustments< >

- 14. < >Check pressure free at “minimess” point

- 15. < >Connect the mini-mesh hose between top

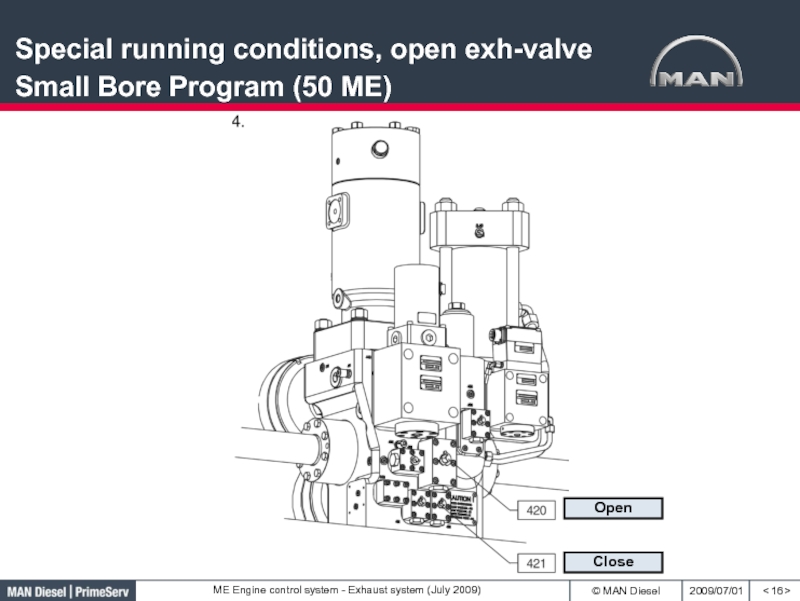

- 16. < >CloseOpenSpecial running conditions, open exh-valve Small Bore Program (50 ME)

- 17. < >Check pressure free at “minimess” point

- 18. < >Close valve 531 toshut off oil

- 19. < >Drain off air pressure from air

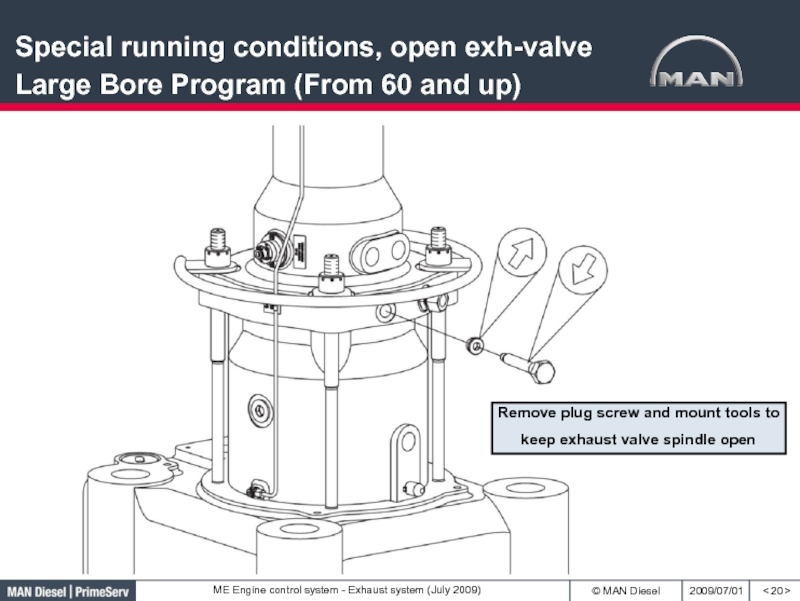

- 20. < >Remove plug screw and mount tools

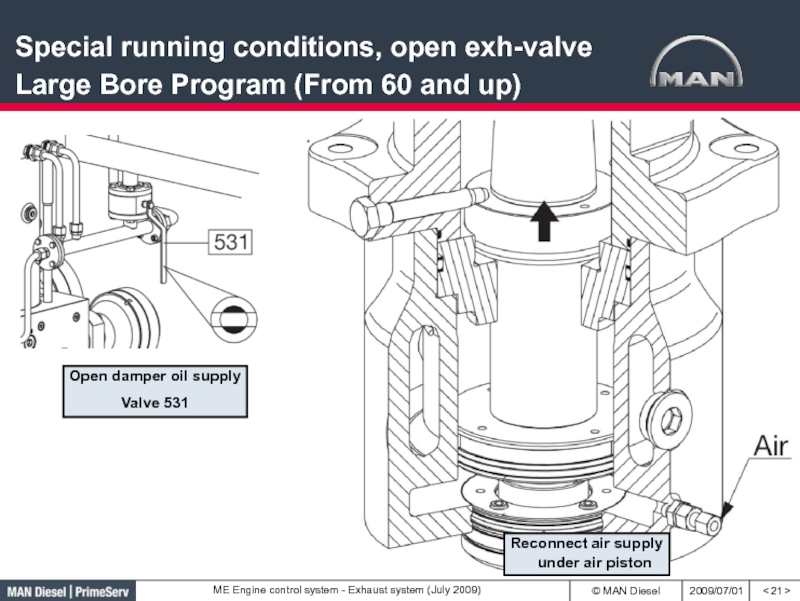

- 21. < >Reconnect air supply under air pistonOpen

- 22. Скачать презентанцию

Exhaust Valve System< >Exhaust valve actuatorExhaust valveSpecial running conditions

Слайды и текст этой презентации

Слайд 8< >

S50MC-C

S50ME-C

Hydraulic damper for fixed valve stroke

Air spring size for

closing the exhaust valve reduced

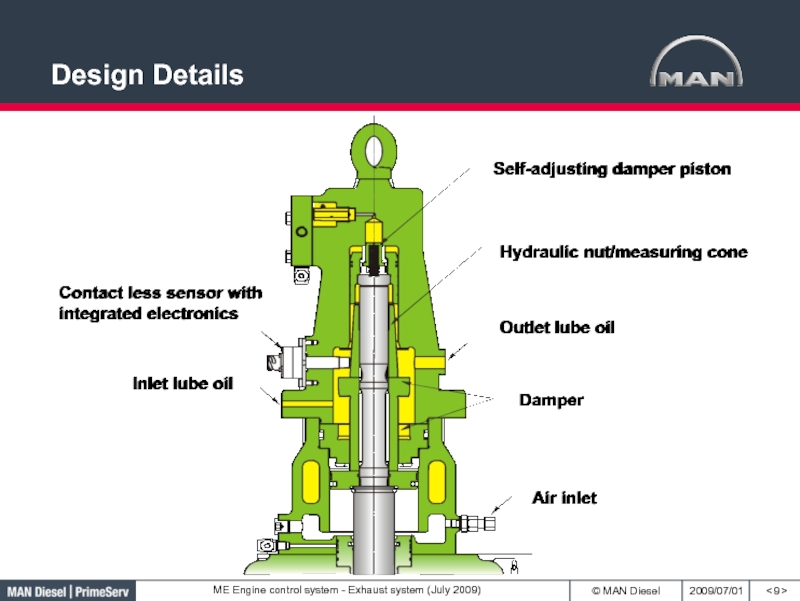

MEСлайд 9< >

Self-adjusting damper piston

Hydraulic nut/measuring cone

Outlet lube oil

Damper

Air inlet

Inlet lube

oil

Contact less sensor with integrated electronics

Design Details

Слайд 14< >

Check pressure free at “minimess” point 455

Close

Open

Special running conditions,

open exh-valve Small Bore Program (50 ME)

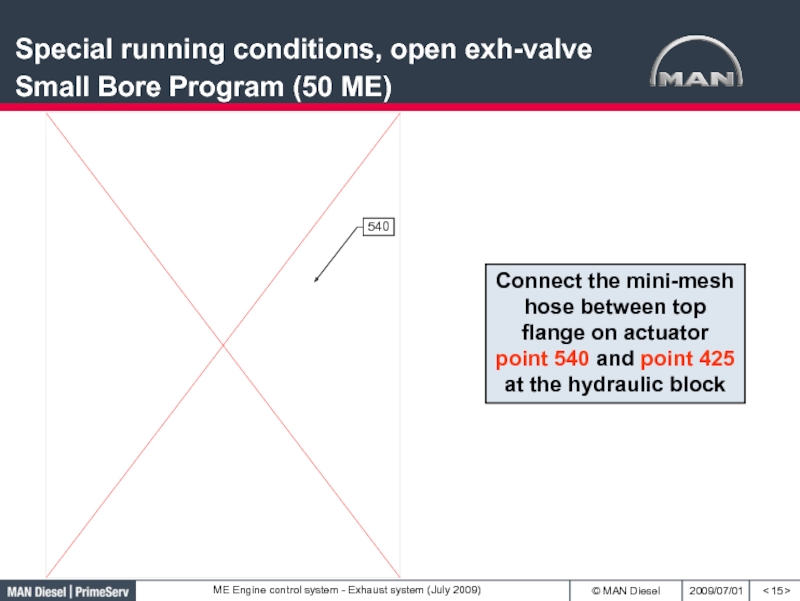

Слайд 15< >

Connect the mini-mesh hose between top flange on actuator

point 540 and point 425 at the hydraulic block

Special

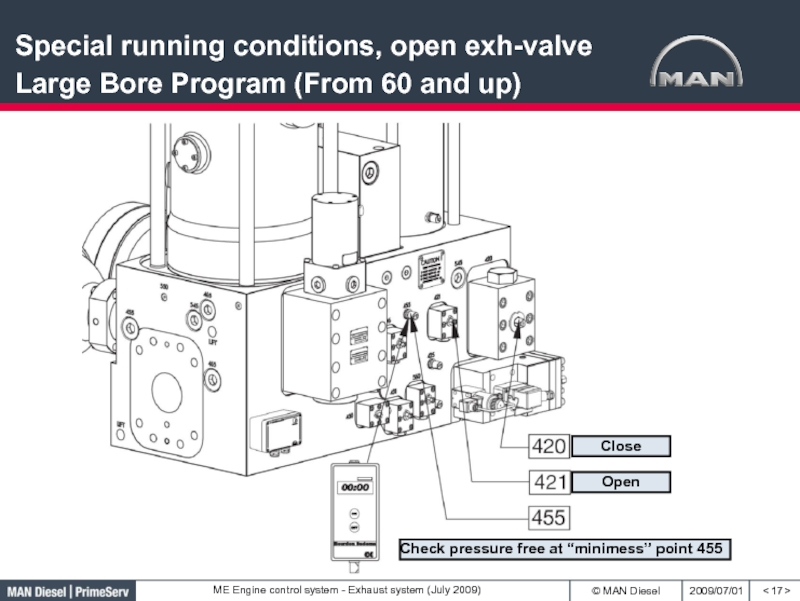

running conditions, open exh-valve Small Bore Program (50 ME)Слайд 17< >

Check pressure free at “minimess” point 455

Close

Open

Special running conditions,

open exh-valve Large Bore Program (From 60 and up)

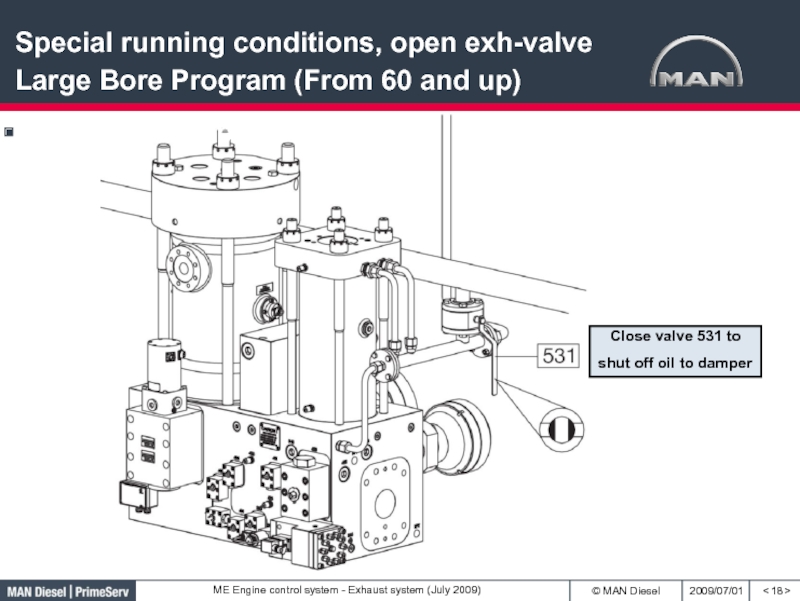

Слайд 18< >

Close valve 531 to

shut off oil to damper

Special running

conditions, open exh-valve Large Bore Program (From 60 and up)

(From

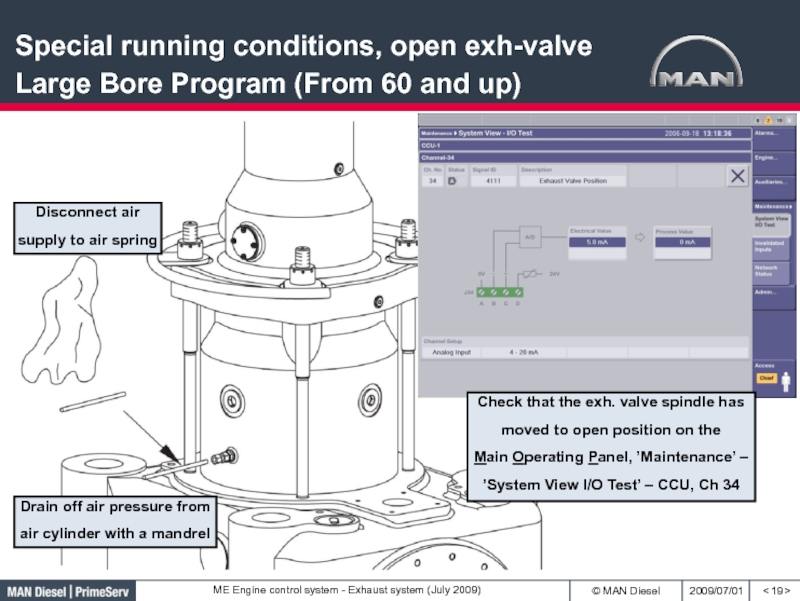

60 and up)Слайд 19< >

Drain off air pressure from

air cylinder with a

mandrel

Disconnect air

supply to air spring

Check that the exh. valve spindle

hasmoved to open position on the

Main Operating Panel, ’Maintenance’ –

’System View I/O Test’ – CCU, Ch 34

Special running conditions, open exh-valve Large Bore Program (From 60 and up)