Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Mobile Phone Recycling system

Содержание

- 1. Mobile Phone Recycling system

- 2. Слайд 2

- 3. The recycling chain for e-waste consists of

- 4. CollectionКартинка сортировочных станций и приемных пунктов телефоновCollection

- 5. sorting/dismantling and pre-processingThe aim of dismantling and

- 6. end-processingAfter removal of the hazardous and other

- 7. integrated smelting/refining operationsTypically an integrated operation starts

- 8. Table 3: Separation and dismantling criteria for e-waste

- 9. conclusionA close interaction and communication among the

- 10. Скачать презентанцию

The recycling chain for e-waste consists of three main subsequent steps: 1) collection, 2)sorting/dismantling and pre-processing (incl. sorting, dismantling, mechanical treatment) and3) end-processing (incl. refining and disposal)Recycling chain

Слайды и текст этой презентации

Слайд 3The recycling chain for e-waste consists of three main subsequent

steps:

1) collection,

2)sorting/dismantling and pre-processing (incl. sorting, dismantling, mechanical

treatment) and3) end-processing (incl. refining and disposal)

Recycling chain

Слайд 4Collection

Картинка сортировочных станций и приемных пунктов телефонов

Collection of e-waste is

of crucial importance as this determines the amount of material

that

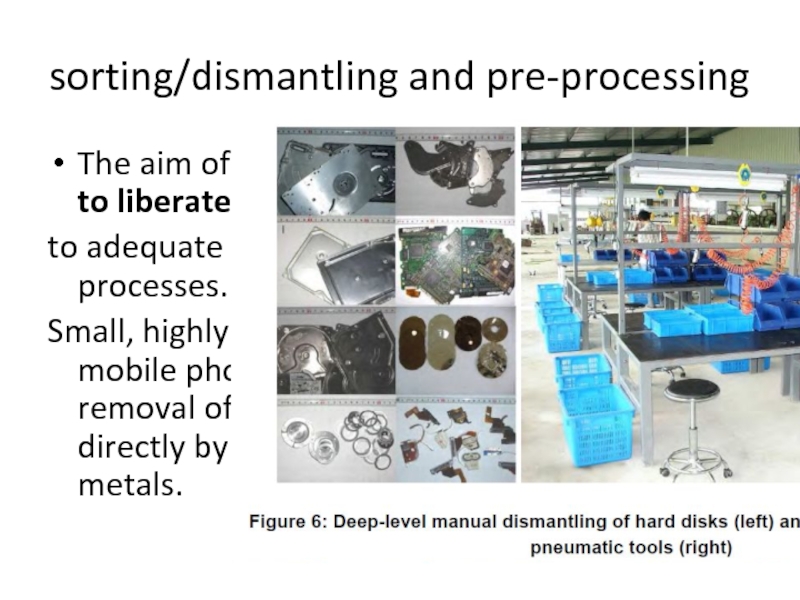

is actually available for recoveryСлайд 5sorting/dismantling and pre-processing

The aim of dismantling and pre-processing is to

liberate the materials and direct them

to adequate subsequent final treatment

processes.Small, highly complex electronic devices such as mobile phones, MP3 players etc. can (after removal of the battery) also be treated directly by an end-processor to recover the metals.

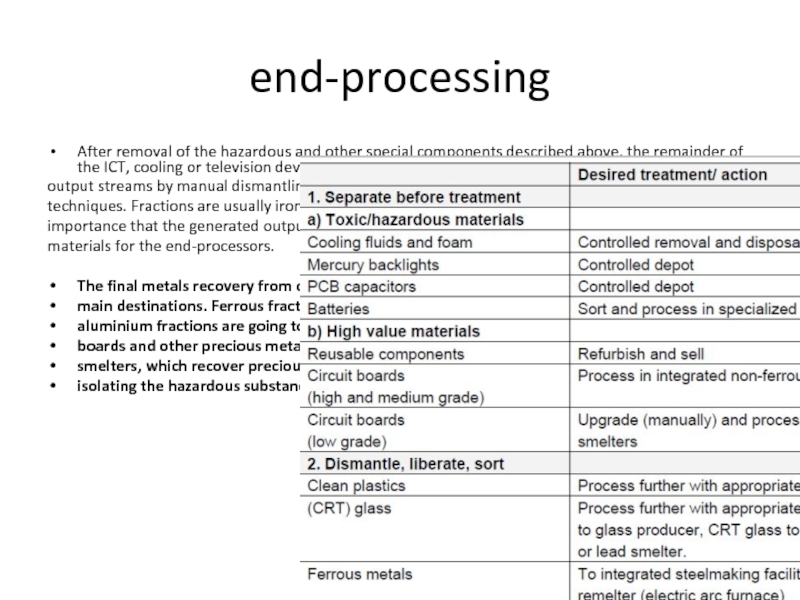

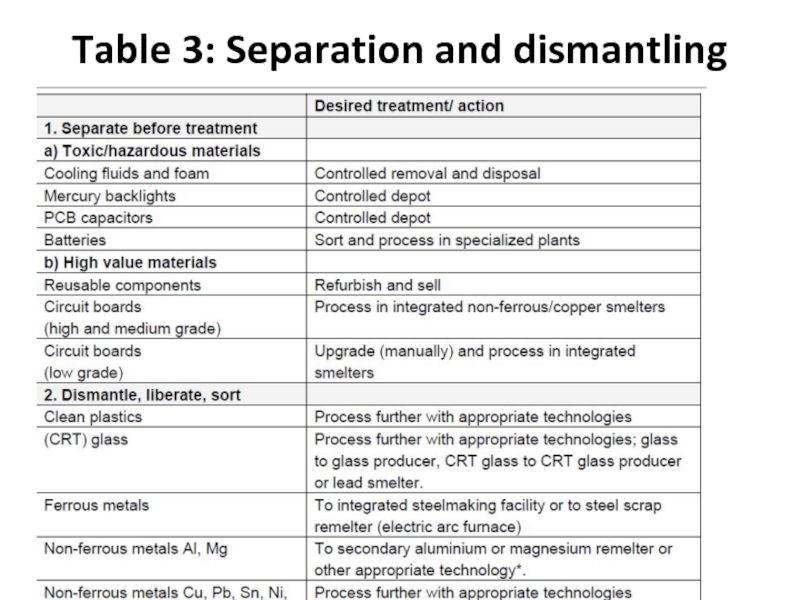

Слайд 6end-processing

After removal of the hazardous and other special components described

above, the remainder of the ICT, cooling or television devices

can be further separated in the materialoutput streams by manual dismantling or mechanical shredding and (automated) sorting

techniques. Fractions are usually iron, aluminium, copper, plastic etc. It is of utmost

importance that the generated output streams meet the quality requirements of the feed

materials for the end-processors.

The final metals recovery from output fractions after pre-treatment takes place at three

main destinations. Ferrous fractions are directed to steel plants for recovery of iron,

aluminium fractions are going to aluminium smelters, while copper/lead fractions, circuit

boards and other precious metals containing fractions are going to e.g. integrated metal

smelters, which recover precious metals, copper and other non-ferrous metals, while

isolating the hazardous substances.

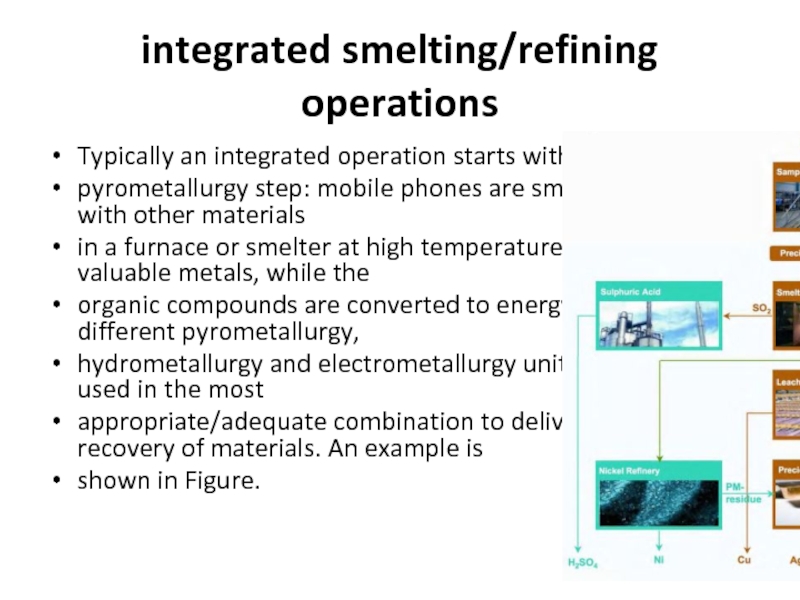

Слайд 7integrated smelting/refining operations

Typically an integrated operation starts with a

pyrometallurgy step:

mobile phones are smelted together with other materials

in a furnace

or smelter at high temperatures to separate the valuable metals, while theorganic compounds are converted to energy. Thereafter, different pyrometallurgy,

hydrometallurgy and electrometallurgy unit operations are used in the most

appropriate/adequate combination to deliver an optimal recovery of materials. An example is

shown in Figure.

Слайд 9conclusion

A close interaction and communication among the participants/stakeholders in the

recycling

chain is thus crucial to achieve a good overall efficiency

and to be able to anticipatefuture developments. Moreover, transparency, accuracy and verification of the actual flows of

materials along the recycling chain are important for all stakeholders. Authorities and

manufacturers need certainty about the actual performance of the involved recycling

operations (in achieving resource efficiency and environmental compliance), so that the legal

or producer responsibility obligations of authorities and manufacturers are fulfilled.