Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

TEM Transmision Electrom Microscope Construction and Application

Содержание

- 1. TEM Transmision Electrom Microscope Construction and Application

- 2. Plan of presentationIntroduction,Selected parts of construction,Electron gun,Lenses,Specimen holder,Image registration,Detectors – different types

- 3. Initial informationSample image is magnified at formed

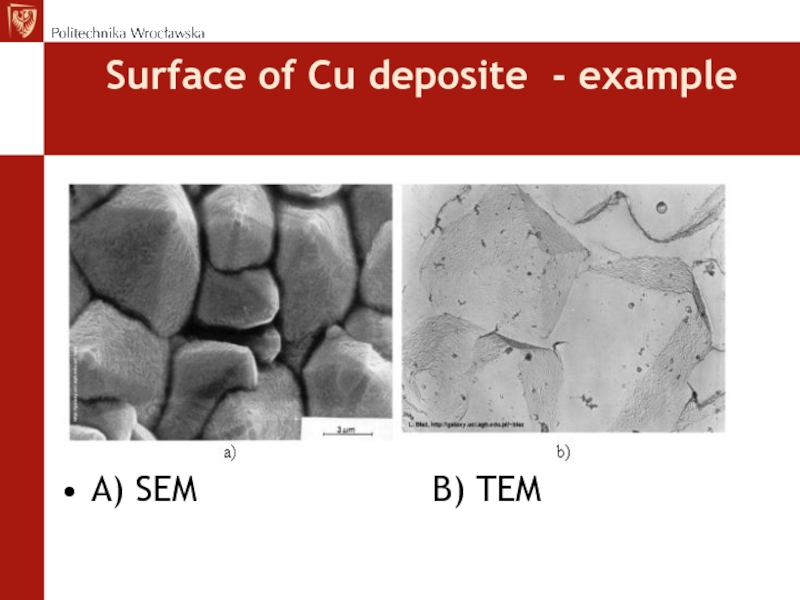

- 4. Surface of Cu deposite - example A)

- 5. Application Presentation of specimens internal structureImages are

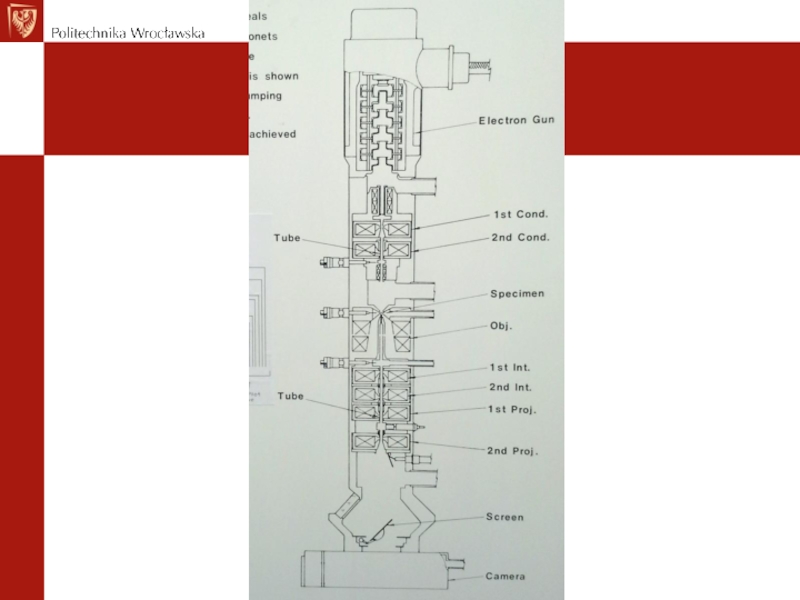

- 6. Basic construction of TEMColumn:Electron gunLenses SpecimenScreen /

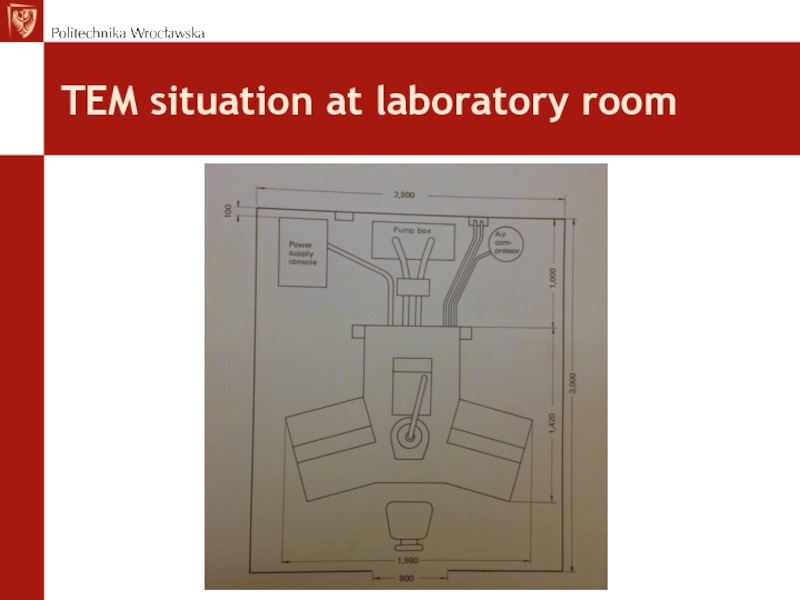

- 7. TEM situation at laboratory room

- 8. Слайд 8

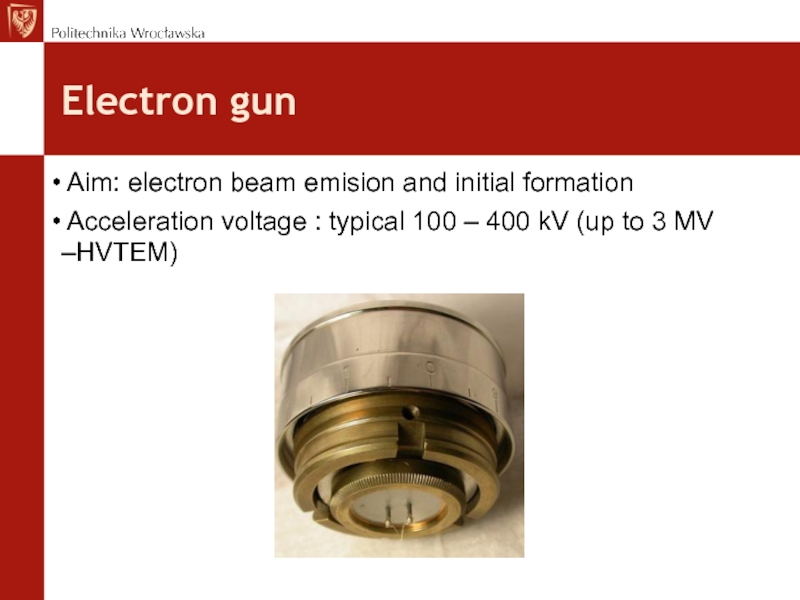

- 9. Electron gun Aim: electron beam emision and

- 10. Electron gun

- 11. Properties of electron guns different types

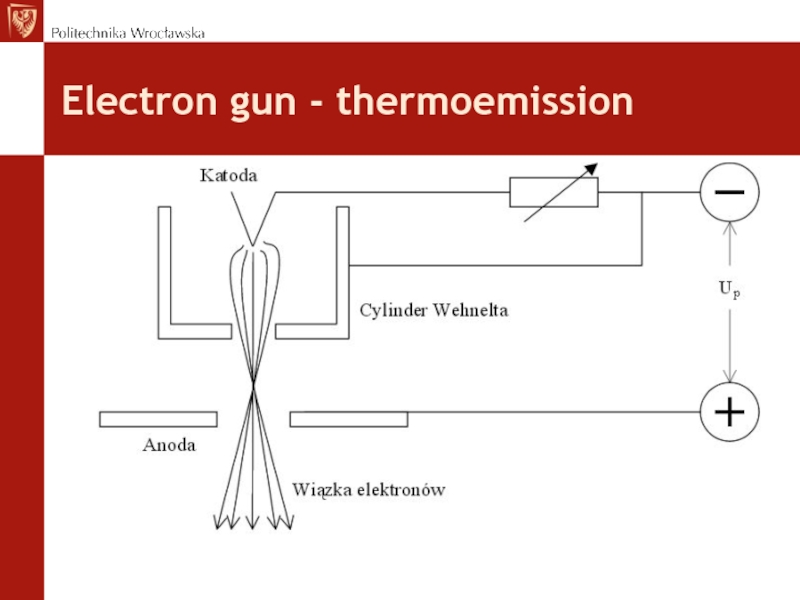

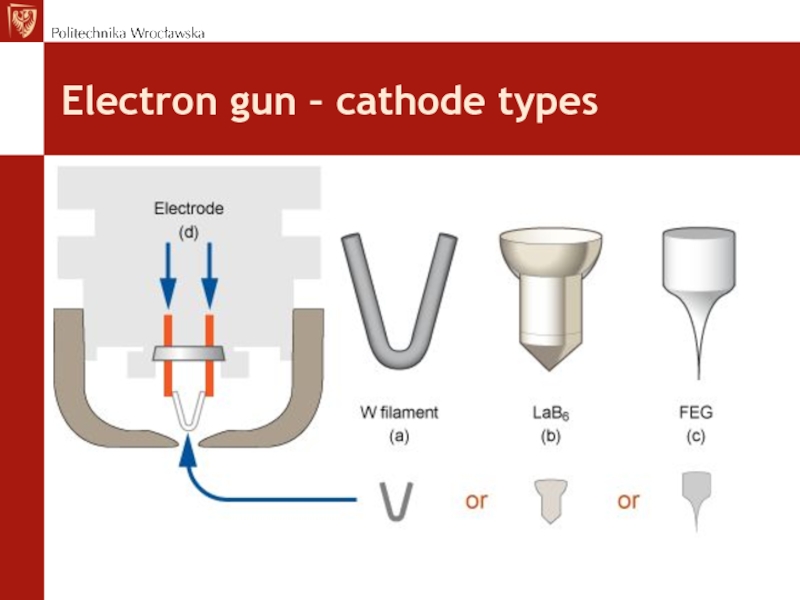

- 12. Electron gun - thermoemission

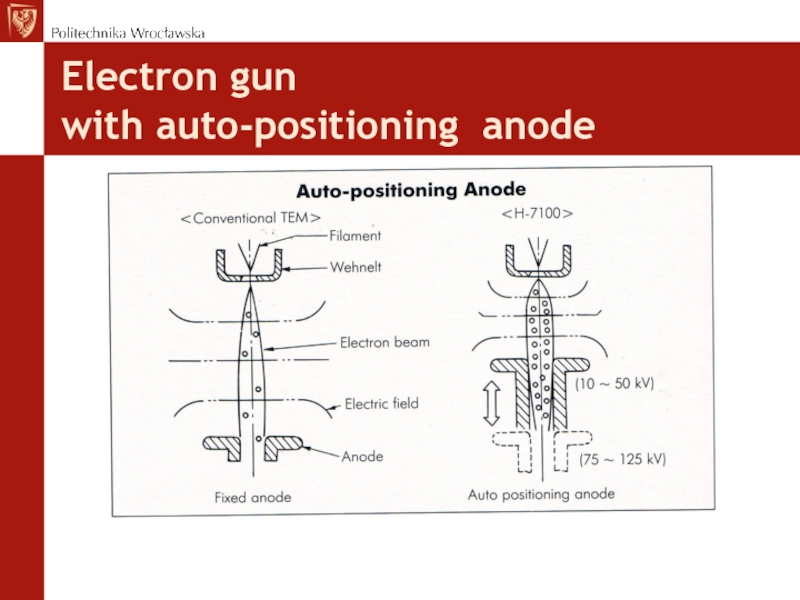

- 13. Electron gun with auto-positioning anode

- 14. Electron gun – cathode types

- 15. Electromagnetic lenses at TEMAre used for changing

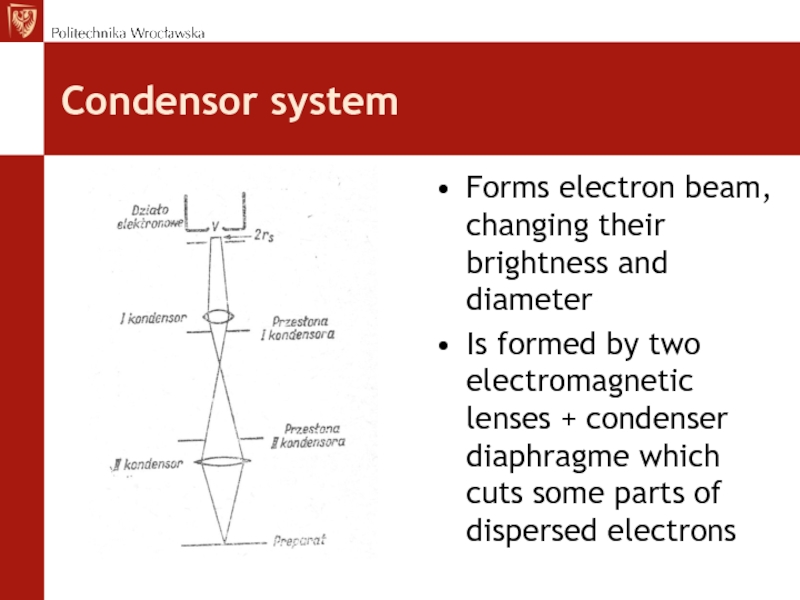

- 16. Condensor systemForms electron beam, changing their brightness

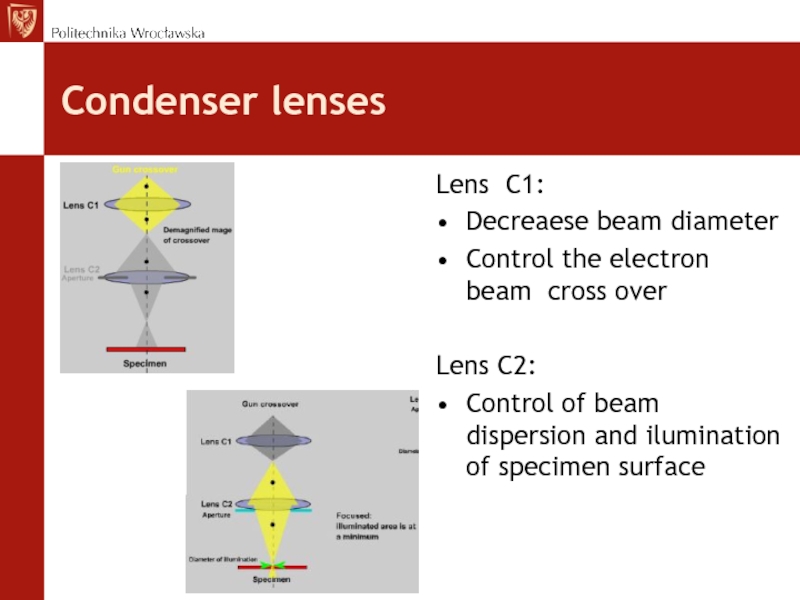

- 17. Condenser lensesLens C1:Decreaese beam diameterControl the electron

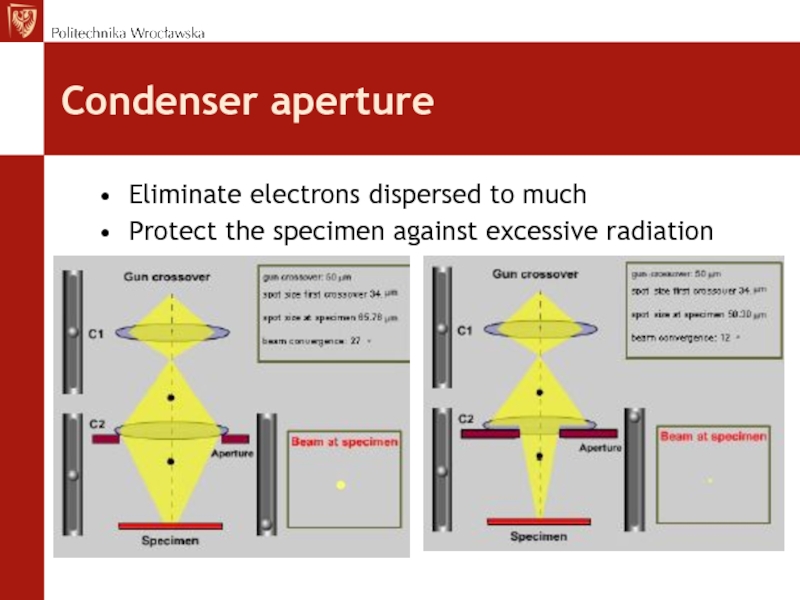

- 18. Condenser apertureEliminate electrons dispersed to muchProtect the specimen against excessive radiation

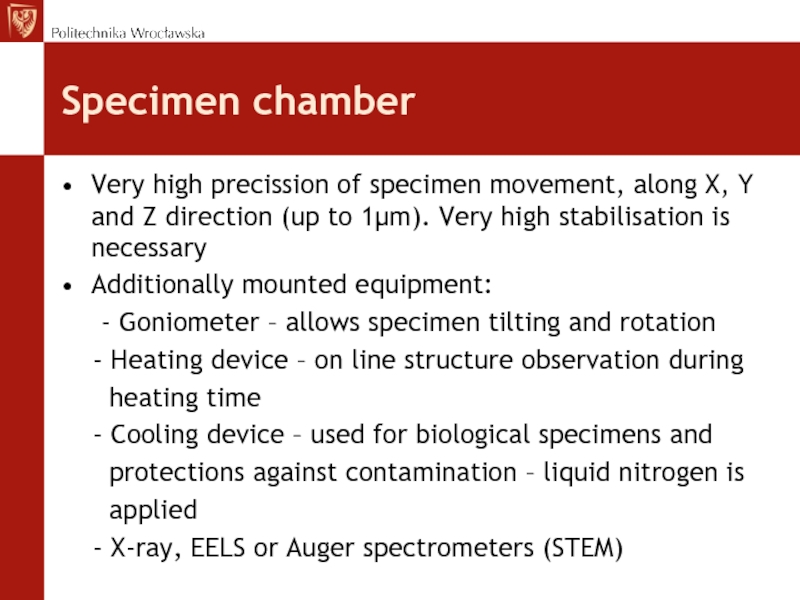

- 19. Specimen chamberVery high precission of specimen movement,

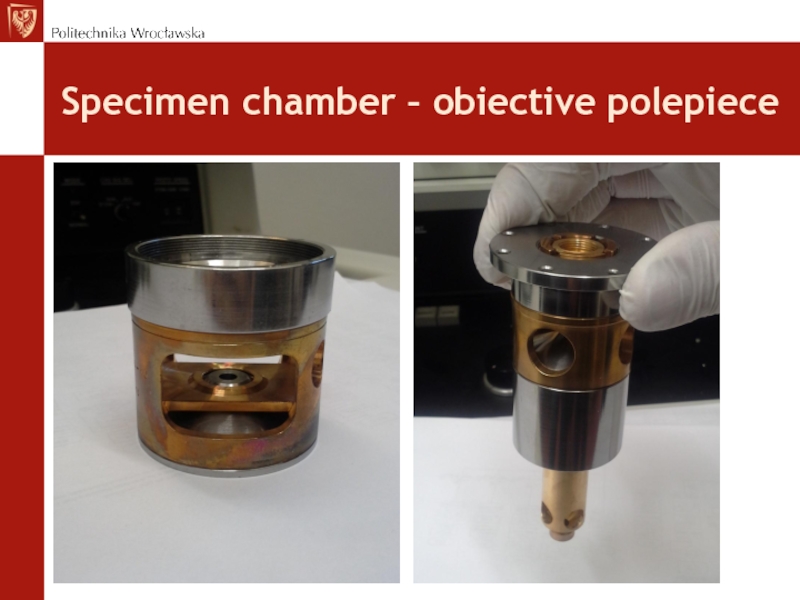

- 20. Specimen chamber – obiective polepiece

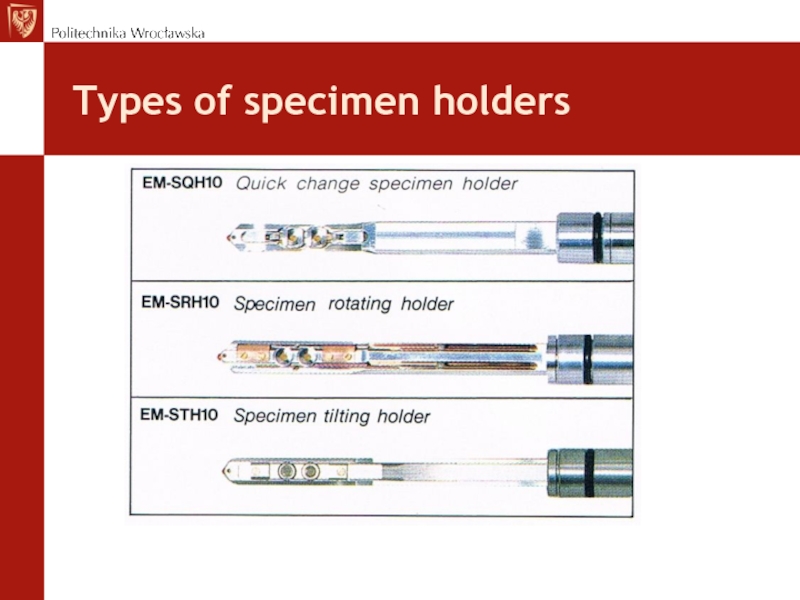

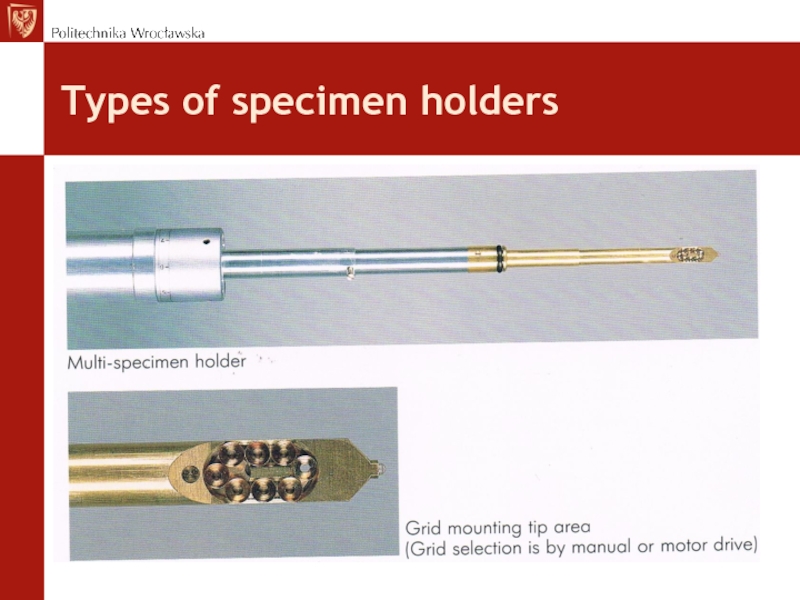

- 21. Types of specimen holders

- 22. Types of specimen holders

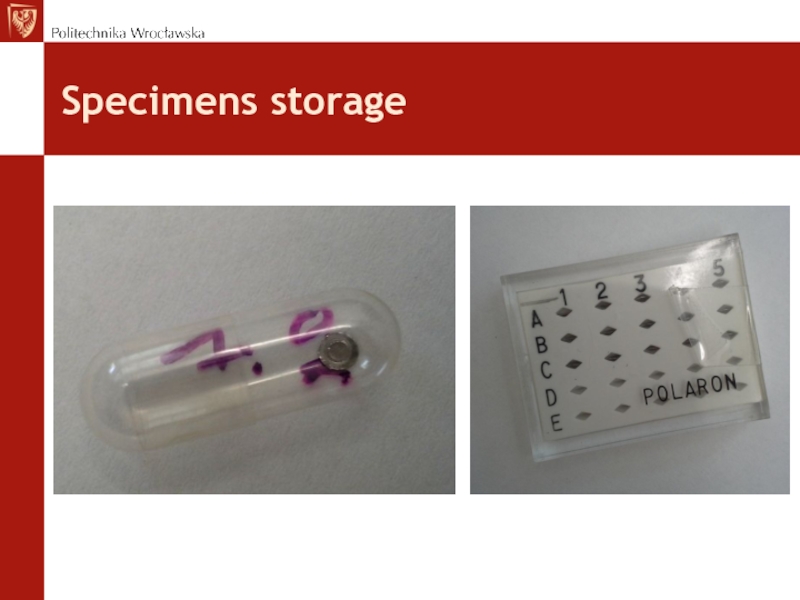

- 23. Specimens storage

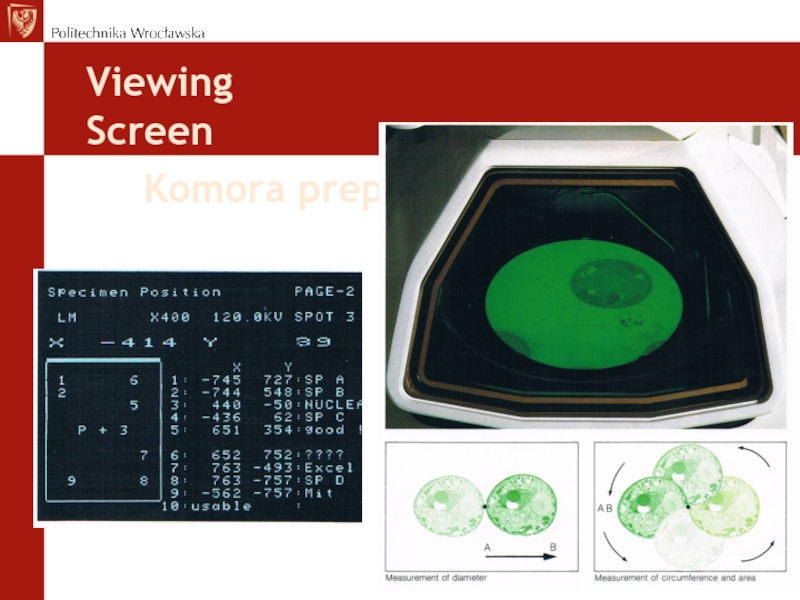

- 24. Komora preparatuViewingScreen

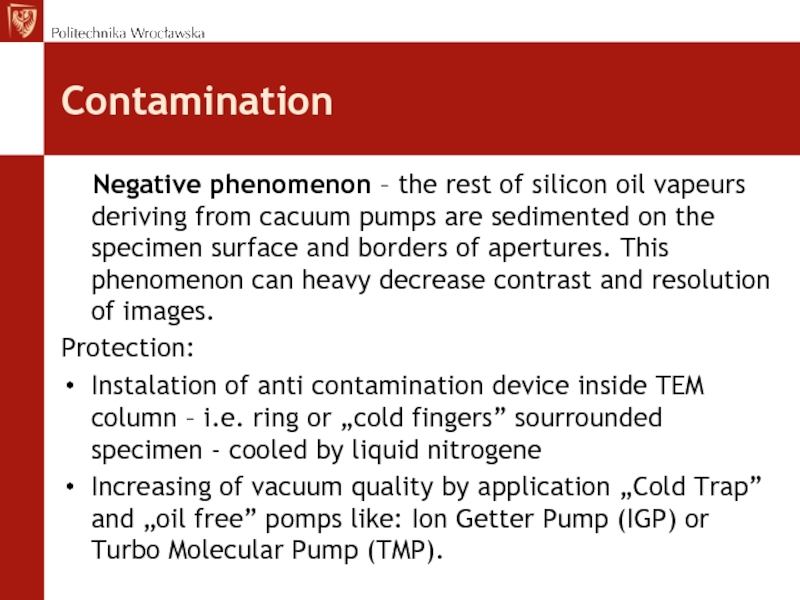

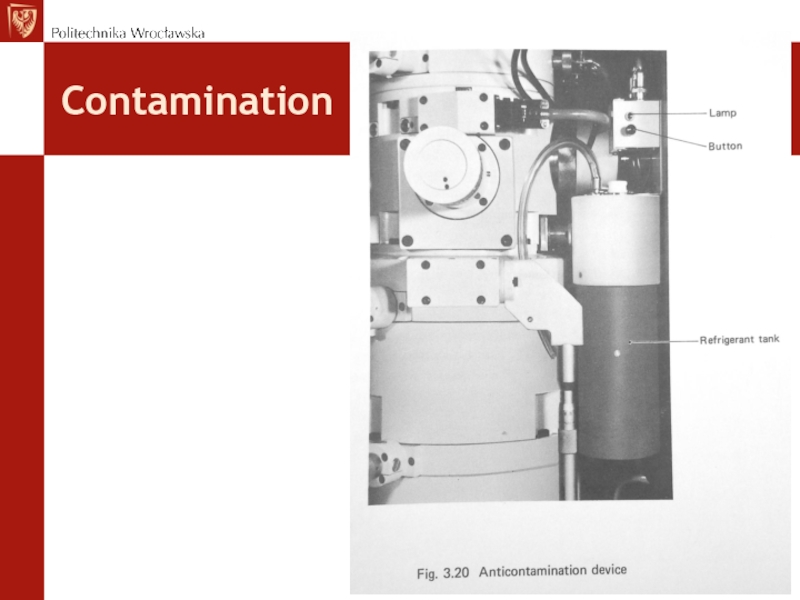

- 25. Contamination Negative phenomenon – the rest

- 26. Contamination

- 27. Position of „Cold Finger” in respect to specimen holder

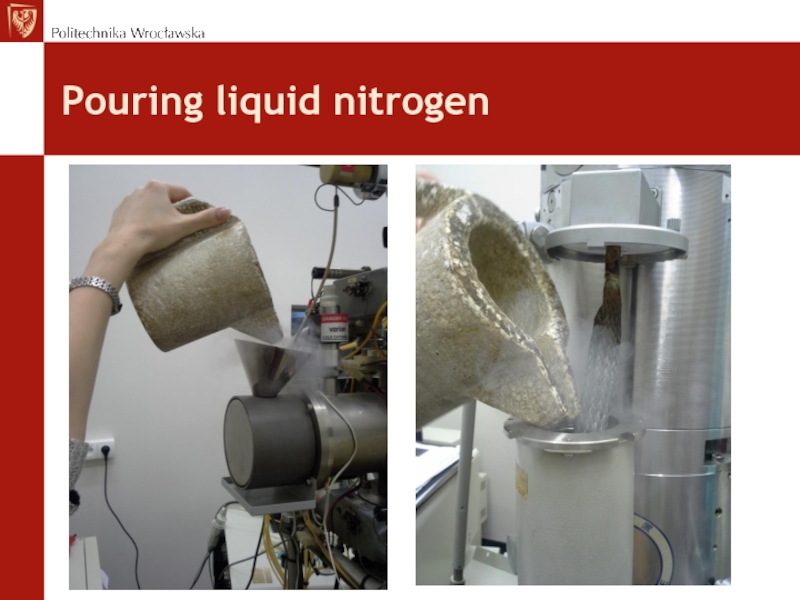

- 28. Pouring liquid nitrogen

- 29. Vacuum systemVacuum is necessary that gas molecules

- 30. Vacuum system - valves

- 31. Vacuum system - rotary pumpReached vacuum:10-2 Pa

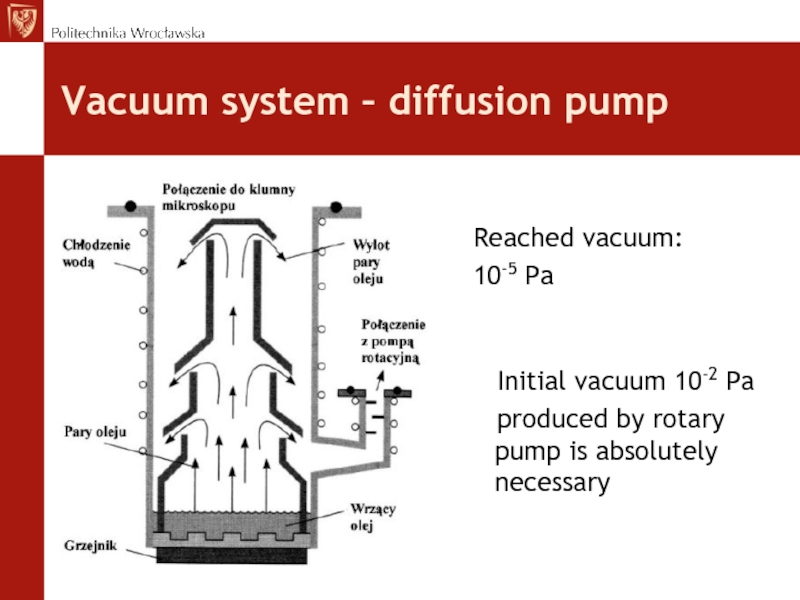

- 32. Vacuum system – diffusion pumpReached vacuum:10-5 Pa

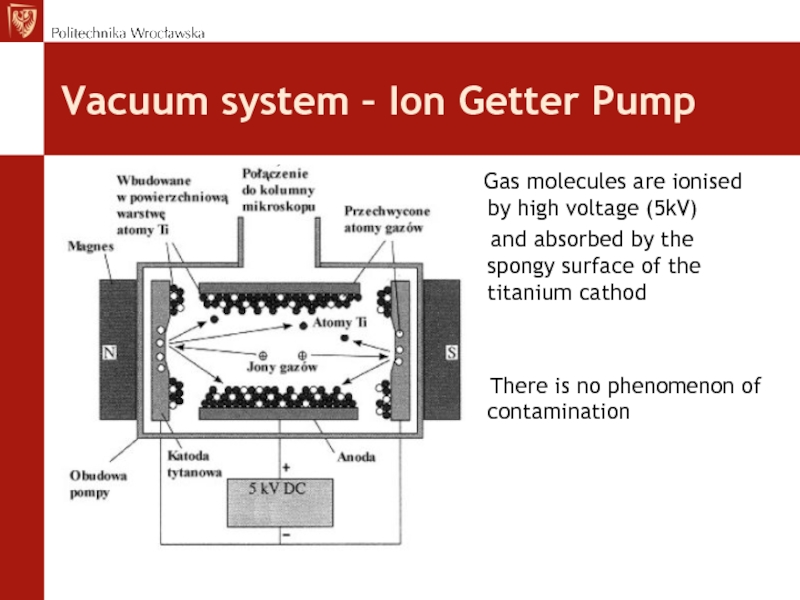

- 33. Vacuum system – Ion Getter Pump

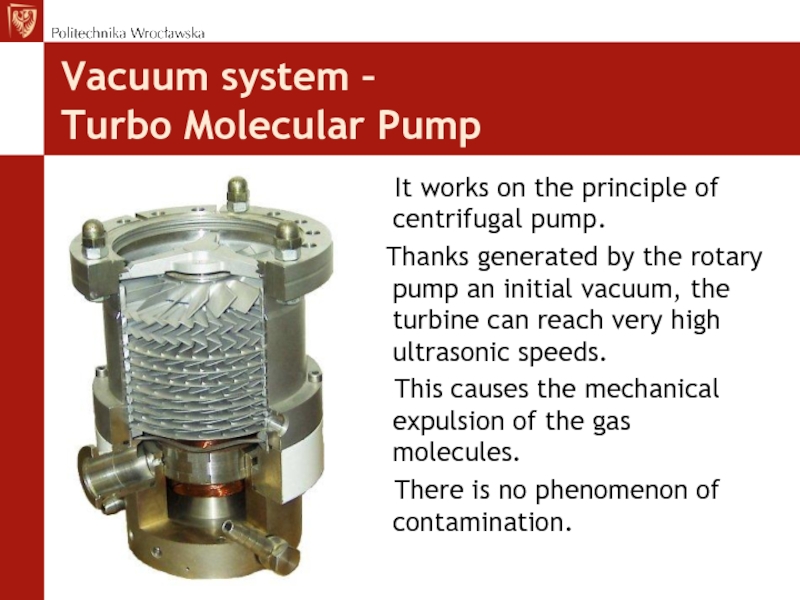

- 34. Vacuum system – Turbo Molecular Pump

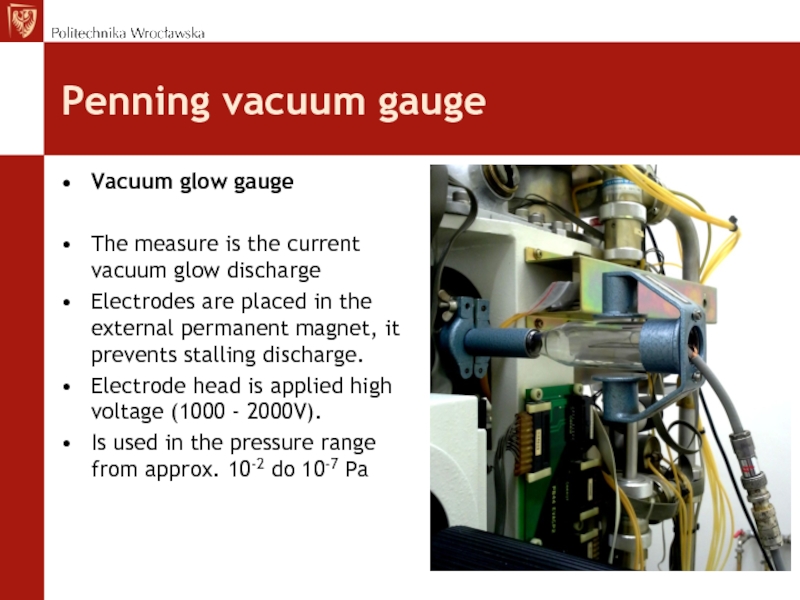

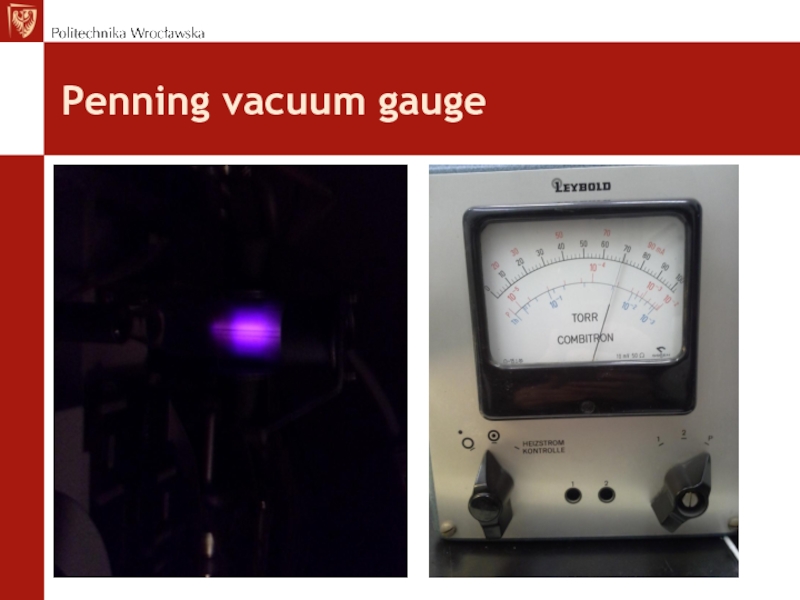

- 35. Penning vacuum gaugeVacuum glow gaugeThe measure is

- 36. Penning vacuum gauge

- 37. Pirani vacuum gaugeVacuum thermal-conductive gauge.The special wire

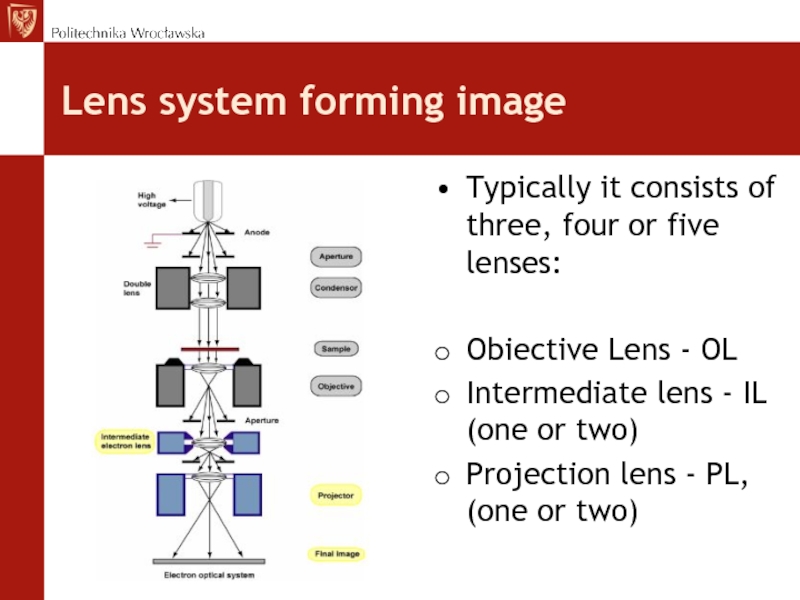

- 38. Lens system forming imageTypically it consists of

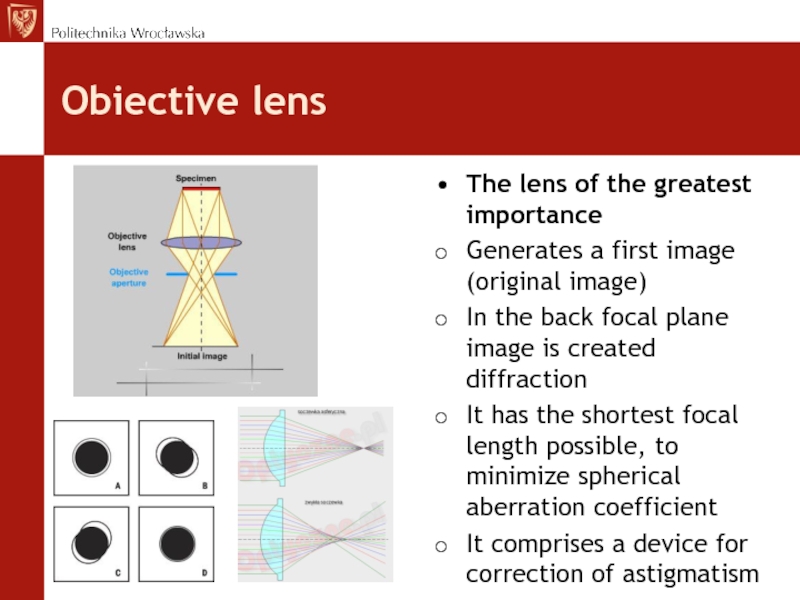

- 39. Obiective lensThe lens of the greatest importanceGenerates

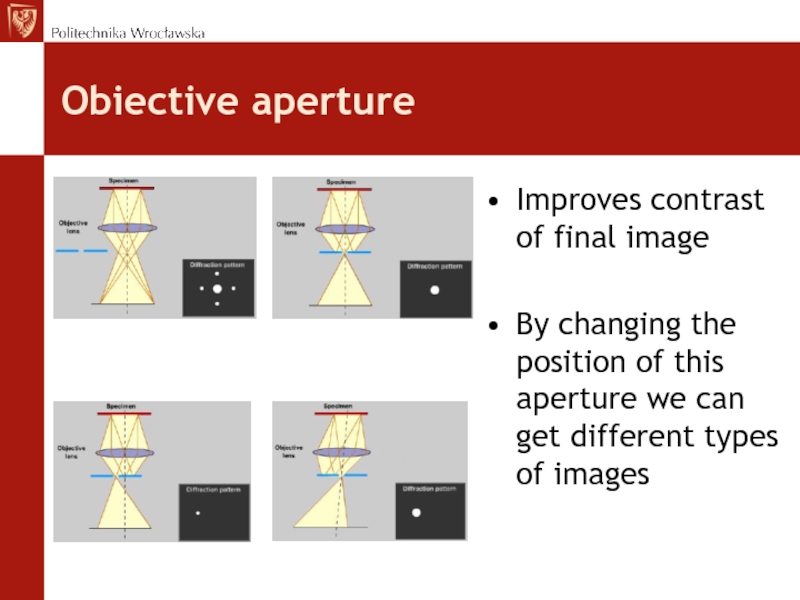

- 40. Obiective apertureImproves contrast of final imageBy changing

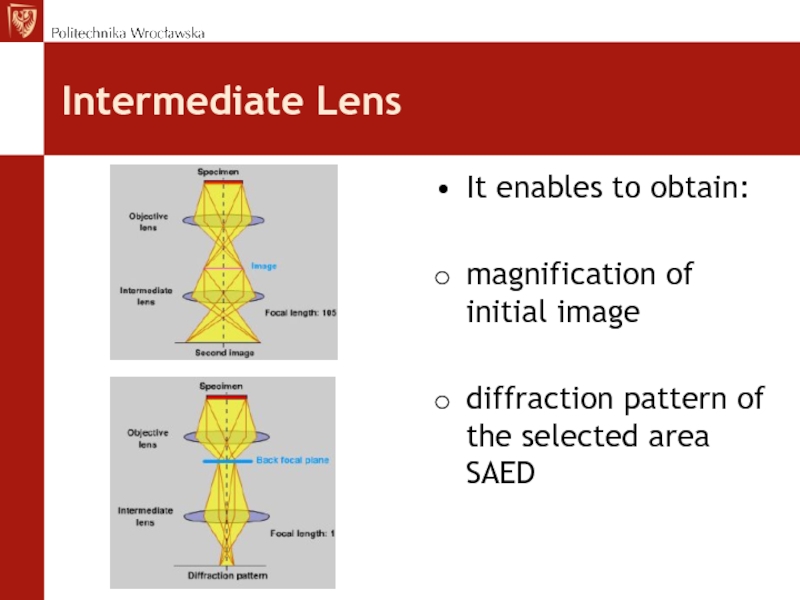

- 41. Intermediate LensIt enables to obtain:magnification of initial imagediffraction pattern of the selected area SAED

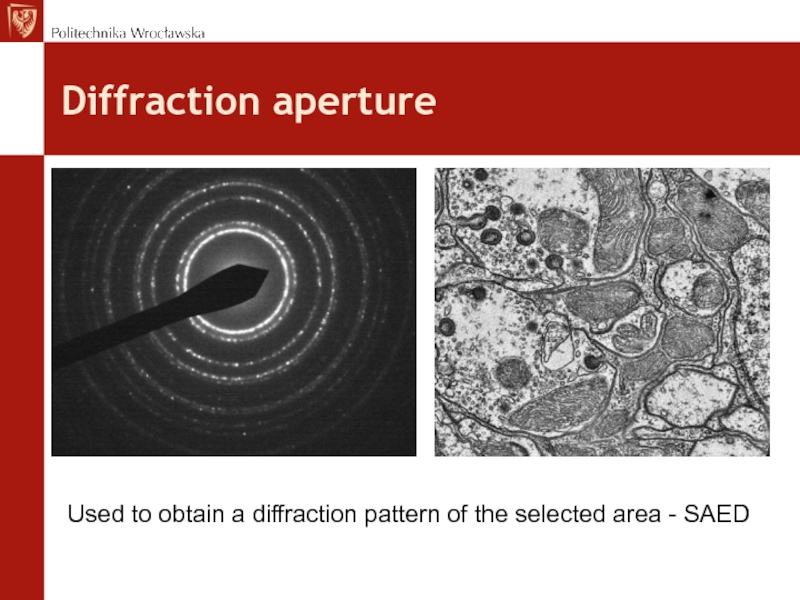

- 42. Diffraction apertureUsed to obtain a diffraction pattern of the selected area - SAED

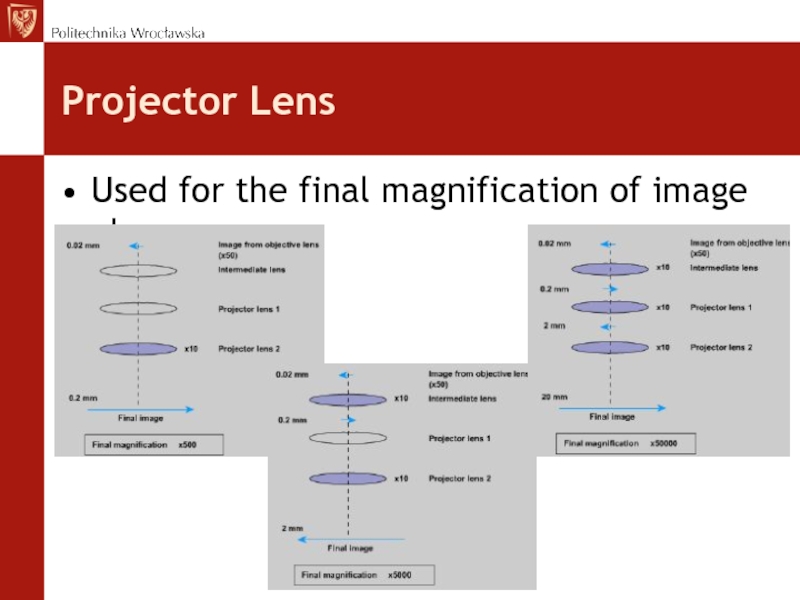

- 43. Projector LensUsed for the final magnification of image obrazu

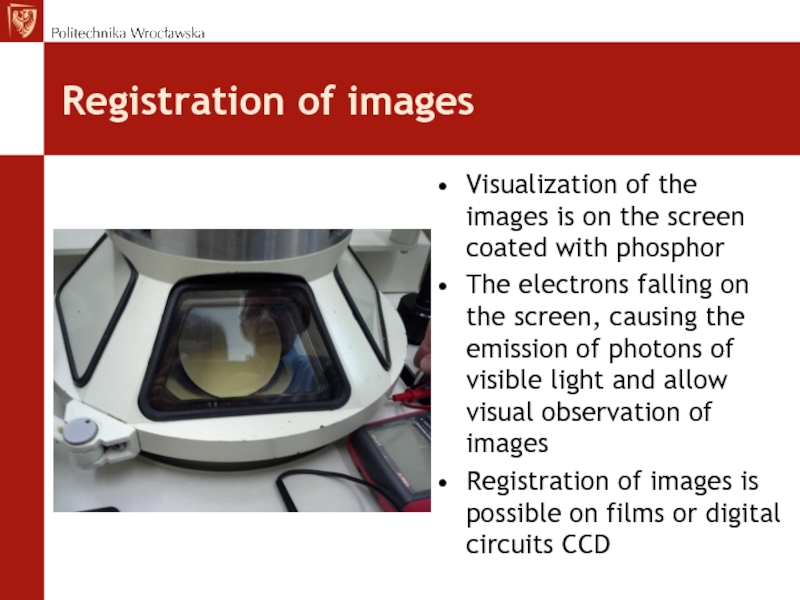

- 44. Registration of imagesVisualization of the images is

- 45. CCD Camera

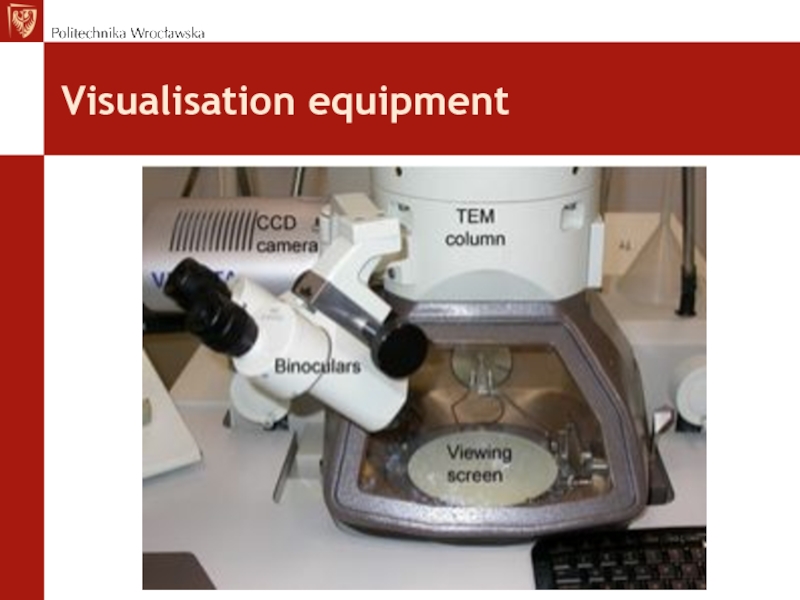

- 46. Visualisation equipment

- 47. Power Supply To ensure production of appropriate

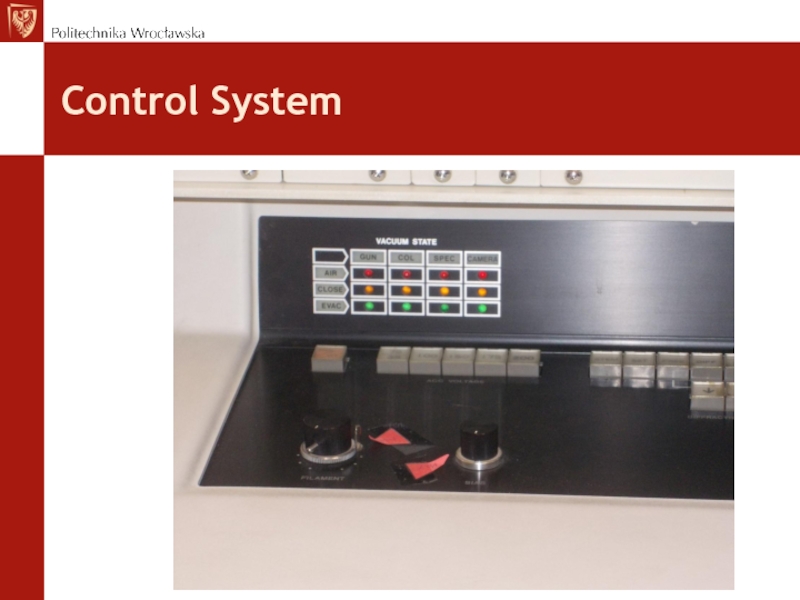

- 48. Control System

- 49. Control System

- 50. Control System

- 51. Control system

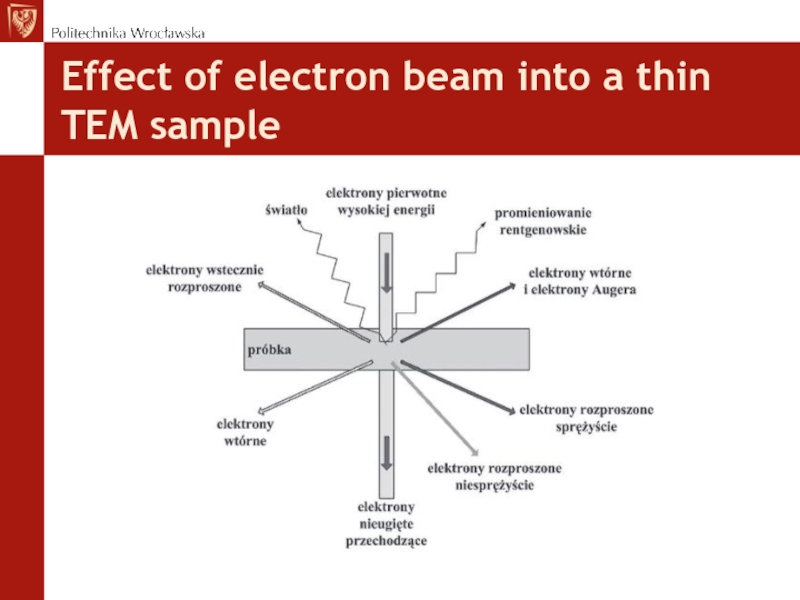

- 52. Effect of electron beam into a thin TEM sample

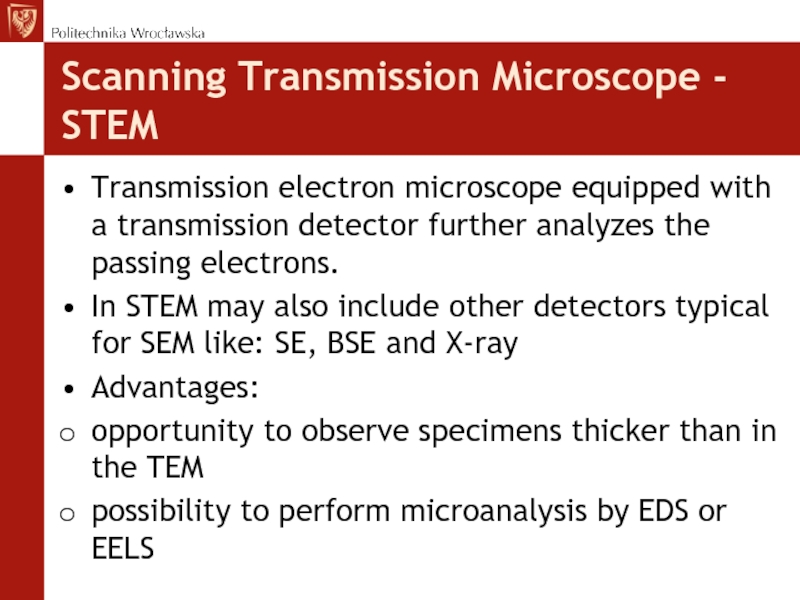

- 53. Scanning Transmission Microscope - STEMTransmission electron microscope

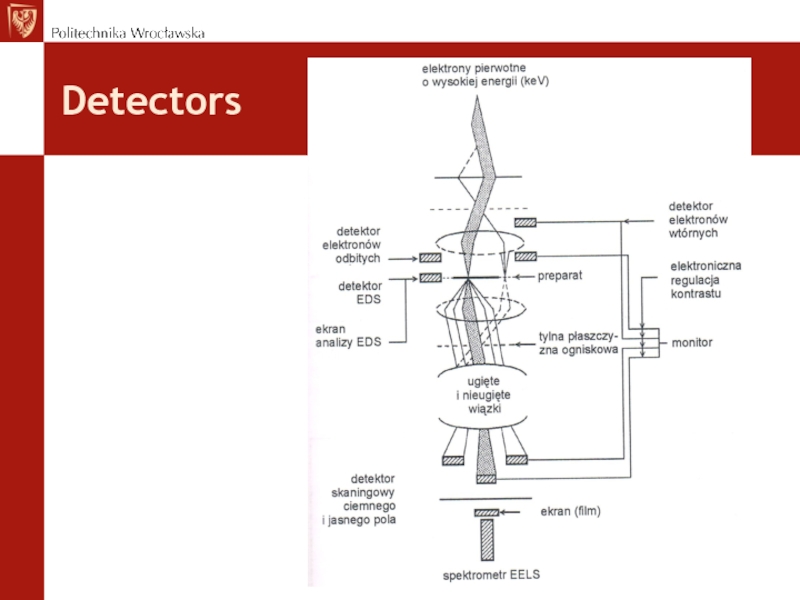

- 54. Detectors

- 55. HVTEM / HRTEMHVTEM – High Voltage TEM

- 56. HVTEM/HRTEM

- 57. HVTEM The amorphous carbon coated with sprayed Li4Ti5O12.

- 58. HVTEM Atomic resolution

- 59. HVHRTEM Atomic resolution:Grain boundaries orientationInterphase boundaries, subgrains,

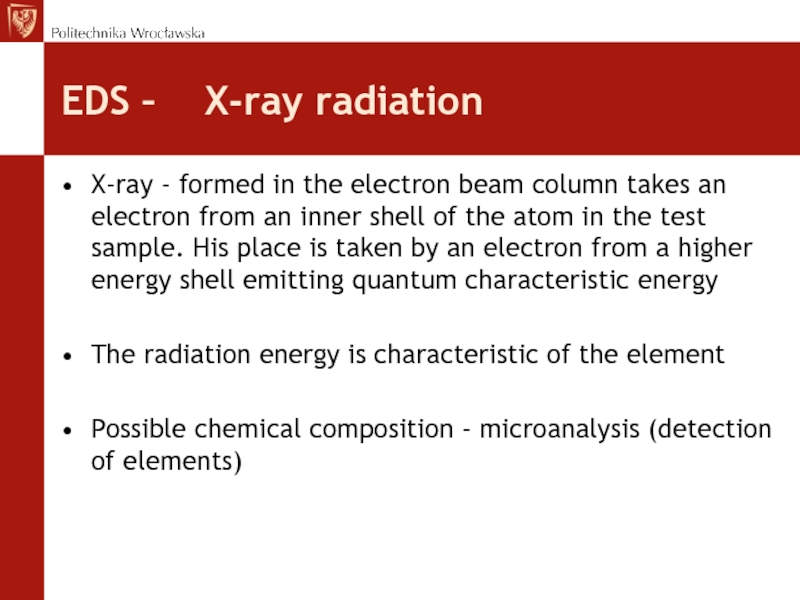

- 60. EDS – X-ray radiationX-ray - formed

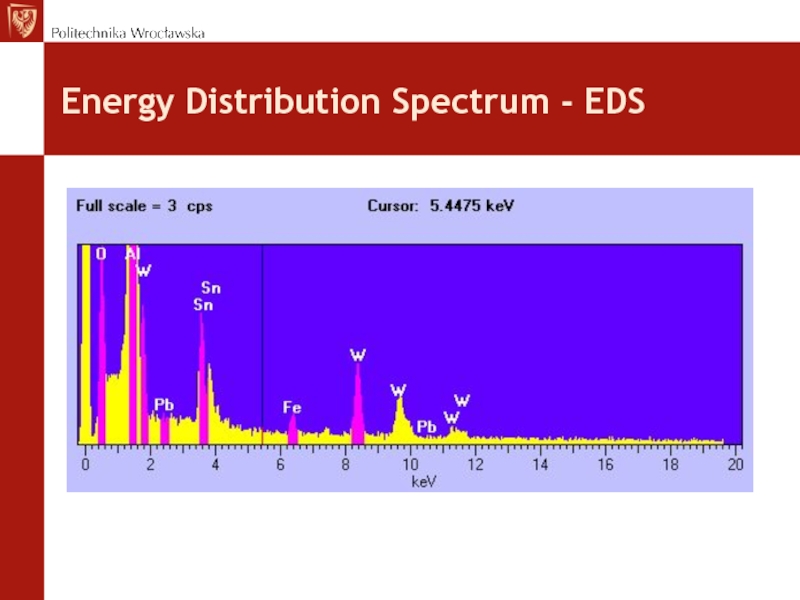

- 61. Energy Distribution Spectrum - EDS

- 62. EELS – Electron Energy Loss SpectroscopySpectroscopy

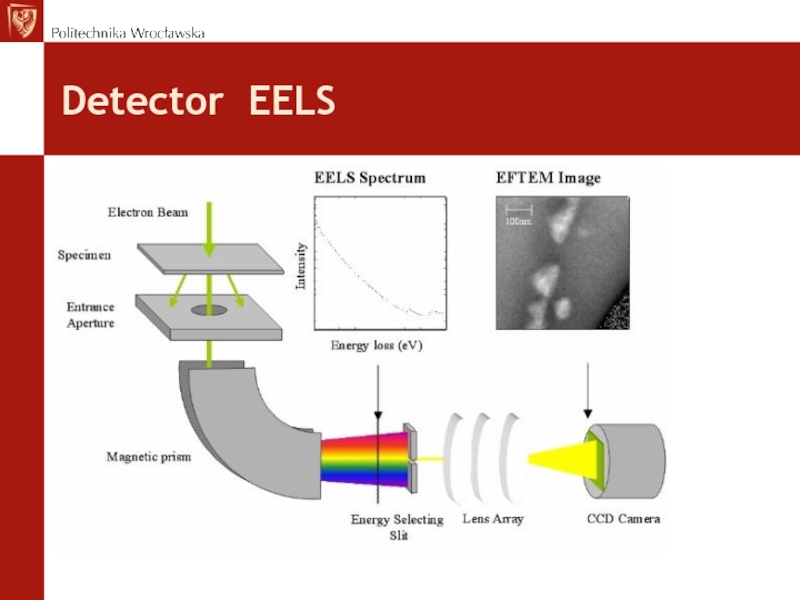

- 63. Detector EELS

- 64. EELS - equipment

- 65. The influence of the sample thickness on research capabilities TEM

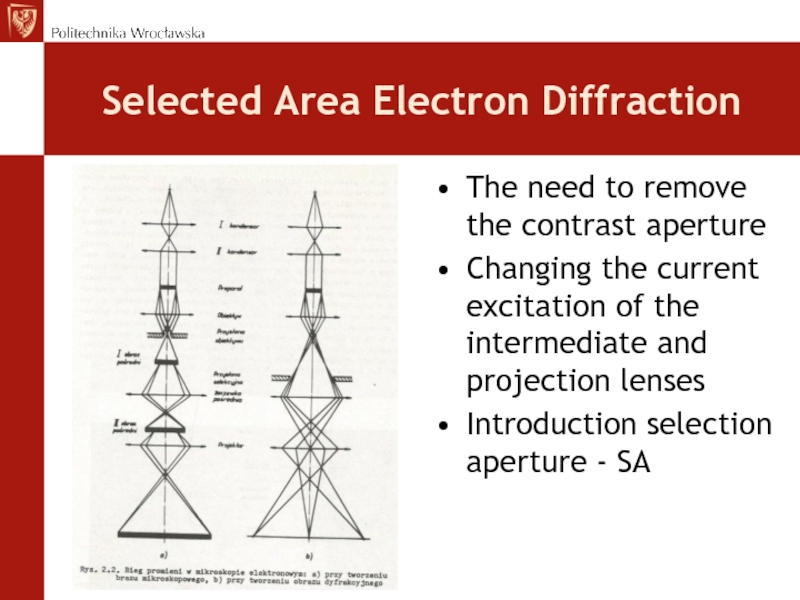

- 66. Selected Area Electron DiffractionThe need to remove

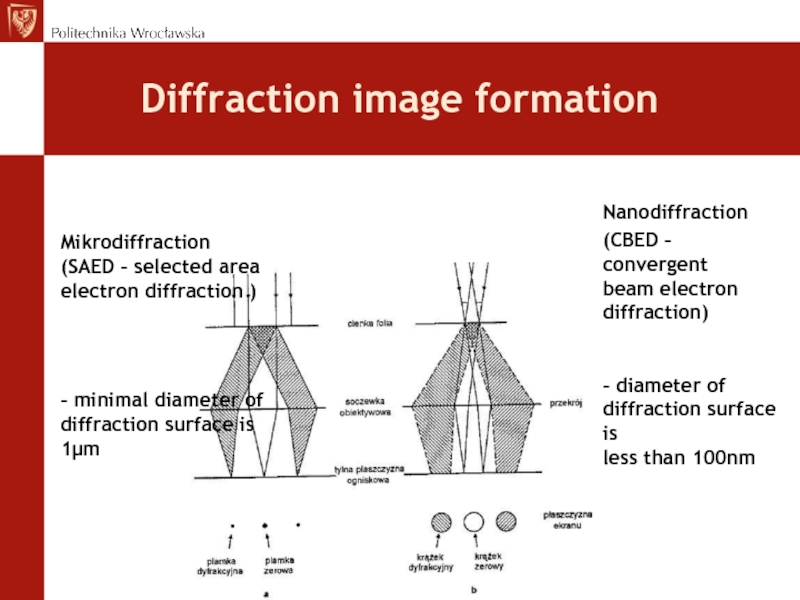

- 67. Diffraction image formation Mikrodiffraction (SAED – selected

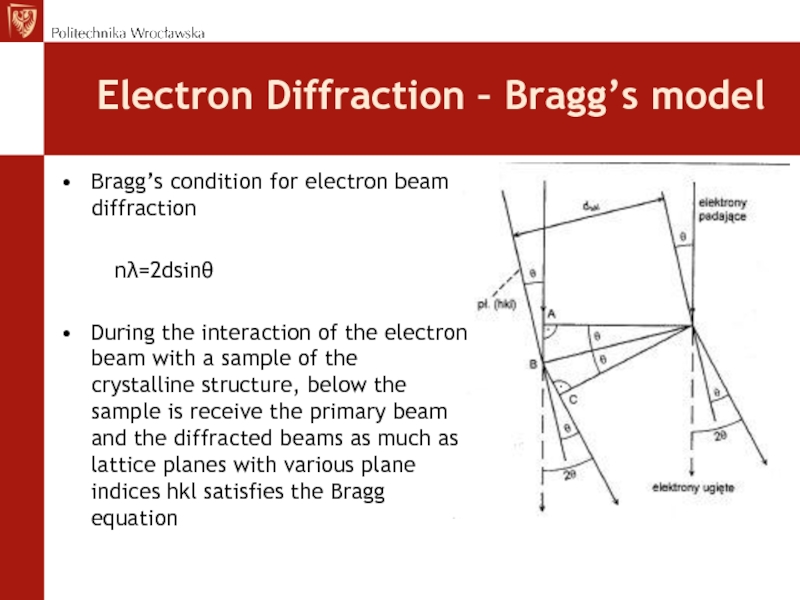

- 68. Electron Diffraction – Bragg’s model Bragg’s

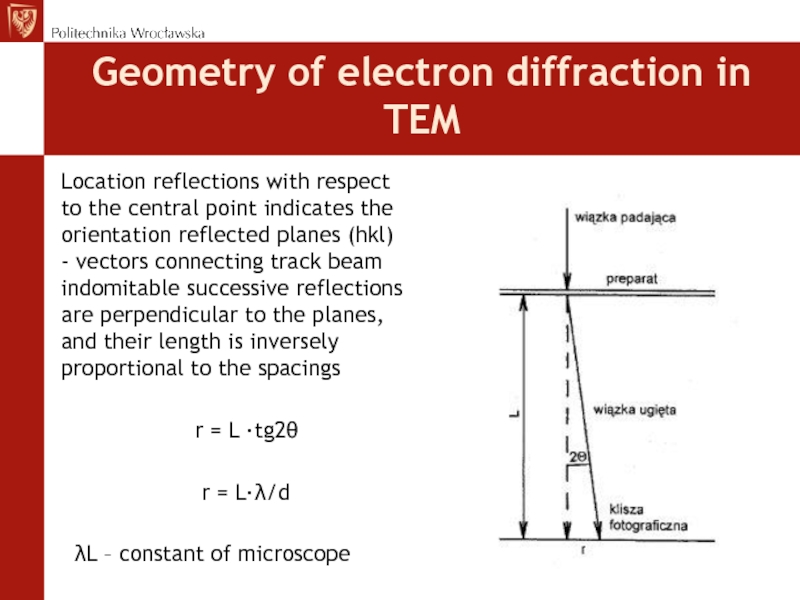

- 69. Geometry of electron diffraction in TEM Location

- 70. Interpretation of electron diffraction patternsIdentification of the

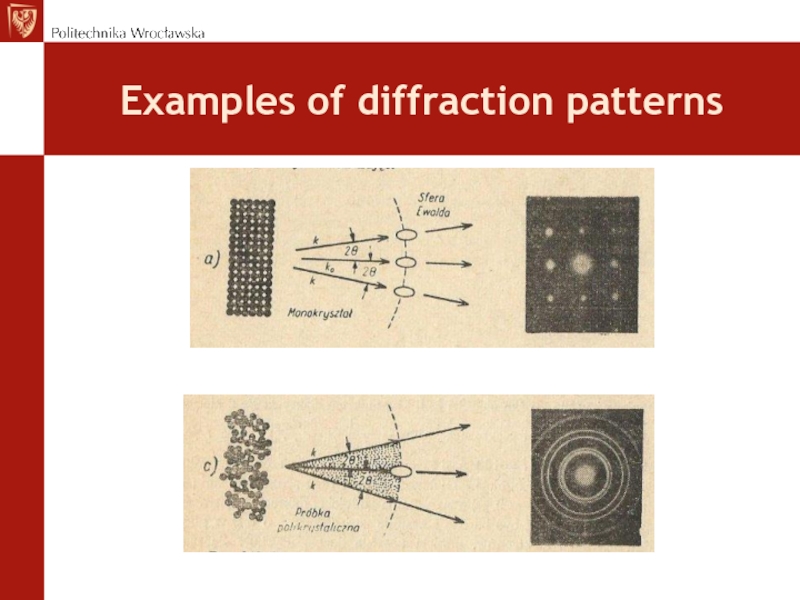

- 71. Application of electron diffraction in materials investigationDiffraction

- 72. Examples of diffraction patterns

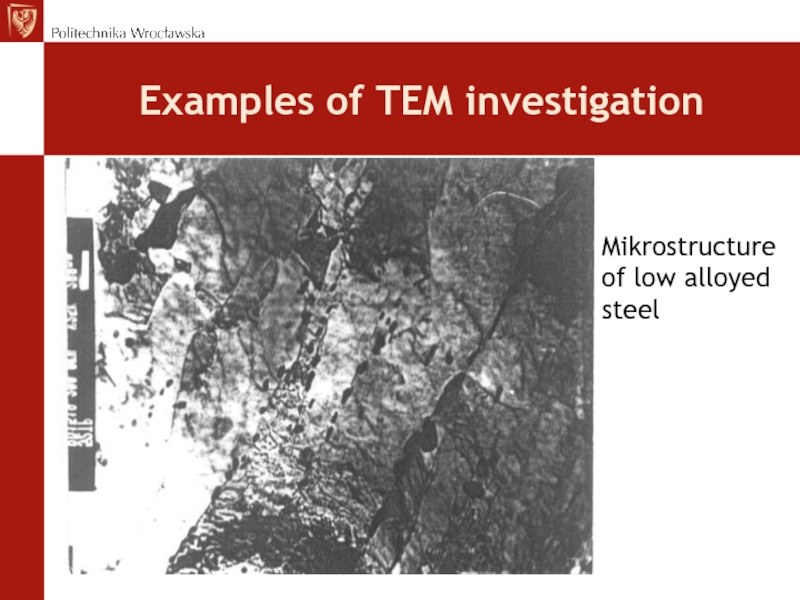

- 73. Examples of TEM investigationMikrostructure of low alloyed steel

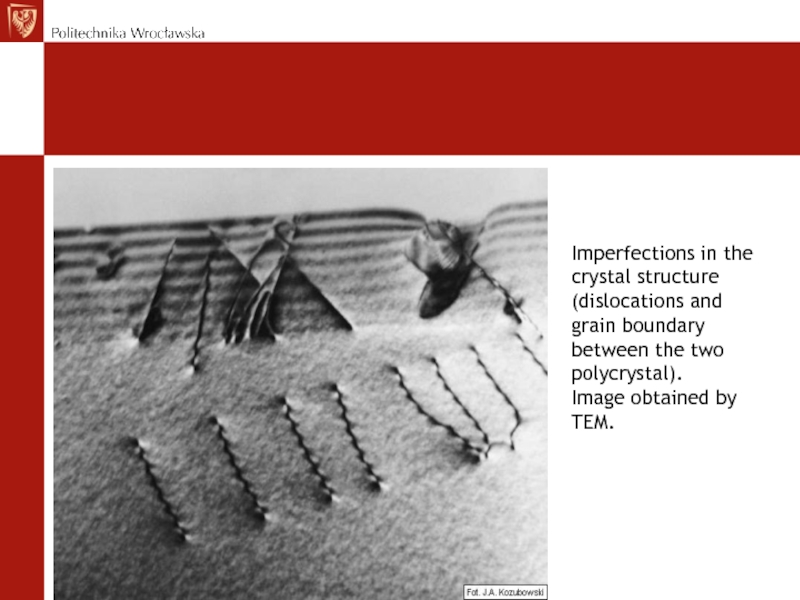

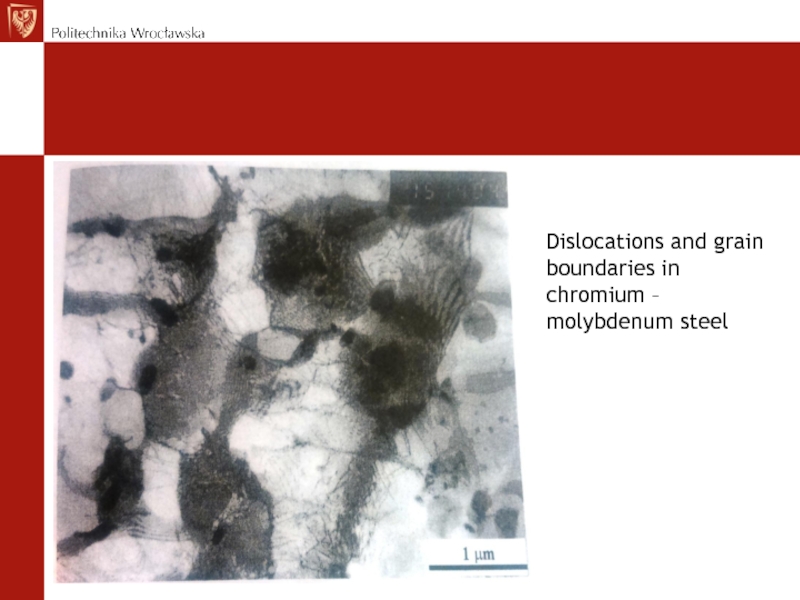

- 74. Imperfections in the crystal structure (dislocations and grain boundary between the two polycrystal).Image obtained by TEM.

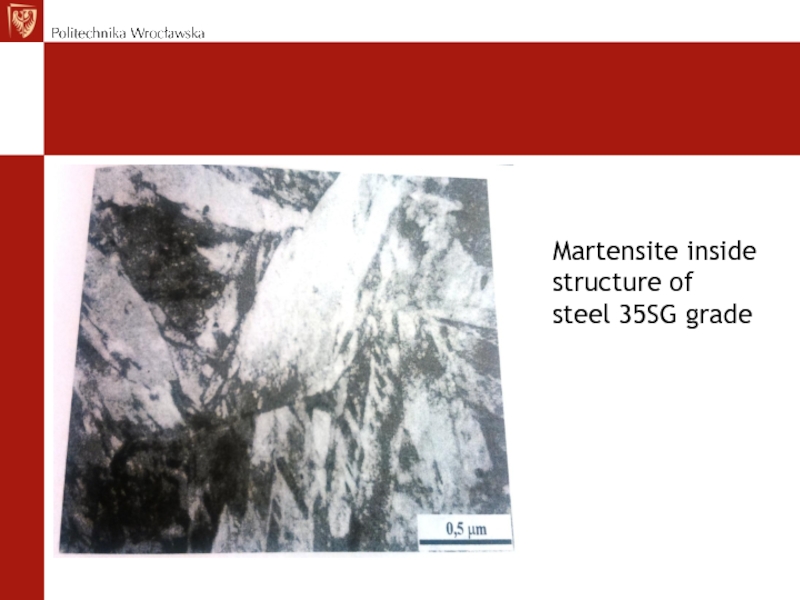

- 75. Martensite inside structure of steel 35SG grade

- 76. Dislocations and grain boundaries in chromium – molybdenum steel

- 77. Structure of the two-phase polymer

- 78. https://www.youtube.com/watch?v=iiJuG636PfQ

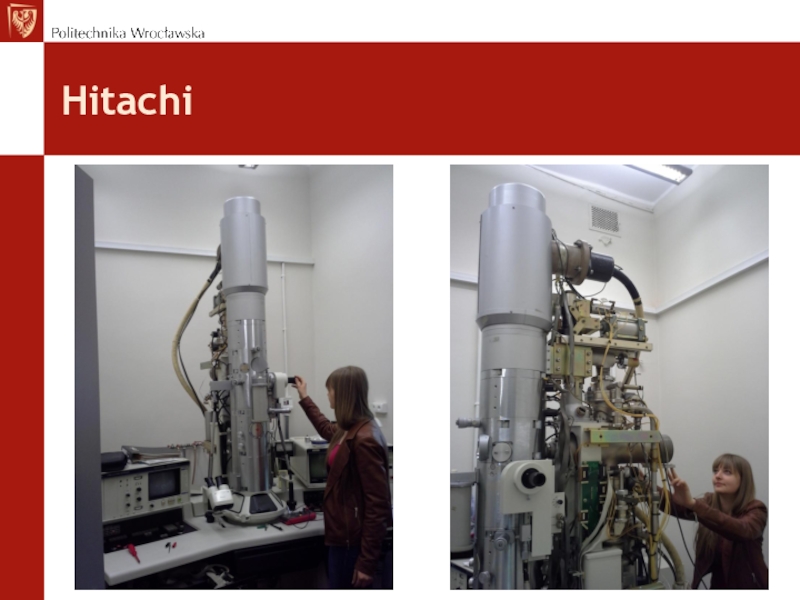

- 79. Hitachi

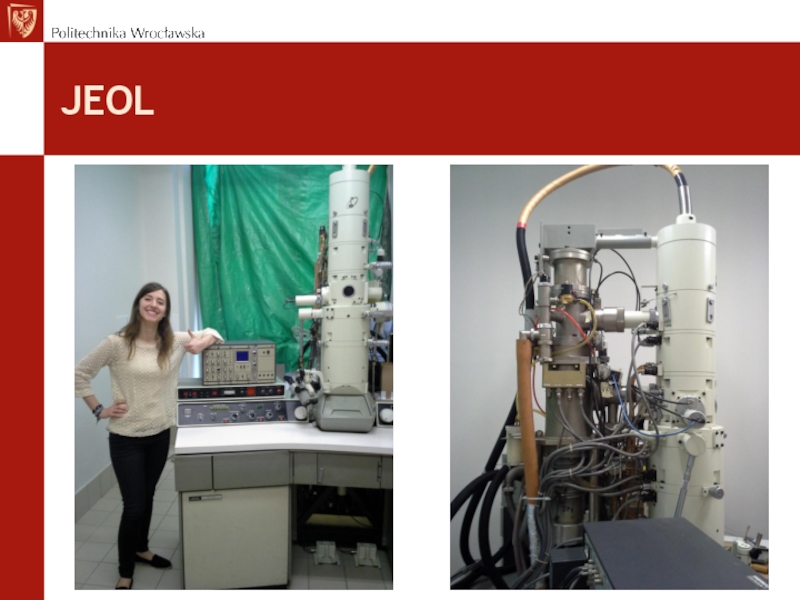

- 80. JEOL

- 81. LiteraturaG. Schimmel, Metodyka mikroskopii elektronowej, PWN, Warszawa

- 82. Скачать презентанцию

Plan of presentationIntroduction,Selected parts of construction,Electron gun,Lenses,Specimen holder,Image registration,Detectors – different types

Слайды и текст этой презентации

Слайд 1TEM

Transmision Electrom Microscope

Construction and Application

Prof. dr habil. ing. Włodzimierz Dudziński

Слайд 2Plan of presentation

Introduction,

Selected parts of construction,

Electron gun,

Lenses,

Specimen holder,

Image registration,

Detectors –

different types

Слайд 3Initial information

Sample image is magnified at formed by electron beam

It

is used for investigation of specime internal structure

Maximale thicknes

of specimen can be 0,1 µmApplied acceleration voltages are from 100kV up to 3 mV ( 3 milion V)

Exploitation is very expensive kosztów

Слайд 5Application

Presentation of specimens internal structure

Images are not coloured

Application at

materials science, biology, medicine and geology

Microstructure, crystalographic orientation, atomic resolution,

chemical composition of different phases can be investigated (HREM, EDX, EELS)3D imaging of specimen is possible (STEM)

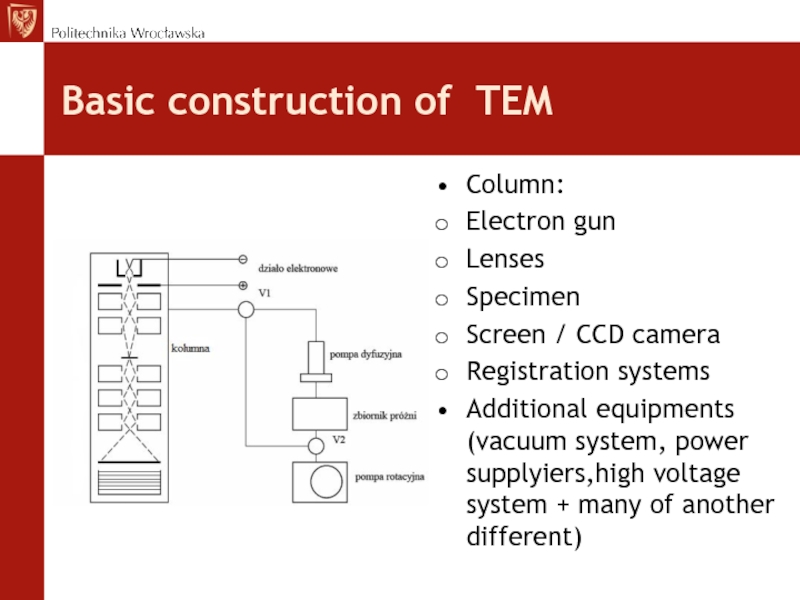

Слайд 6Basic construction of TEM

Column:

Electron gun

Lenses

Specimen

Screen / CCD camera

Registration systems

Additional

equipments (vacuum system, power supplyiers,high voltage system + many of

another different)Слайд 9Electron gun

Aim: electron beam emision and initial formation

Acceleration

voltage : typical 100 – 400 kV (up to 3

MV –HVTEM)Слайд 15Electromagnetic lenses at TEM

Are used for changing characteristic of electron

beam

Brightness

Concentration

Focusing

Are constructed like coils of coper wires

Слайд 16Condensor system

Forms electron beam, changing their brightness and diameter

Is formed

by two electromagnetic lenses + condenser diaphragme which cuts some

parts of dispersed electronsСлайд 17Condenser lenses

Lens C1:

Decreaese beam diameter

Control the electron beam cross over

Lens

C2:

Control of beam dispersion and ilumination of specimen surface

Слайд 18Condenser aperture

Eliminate electrons dispersed to much

Protect the specimen against excessive

radiation

Слайд 19Specimen chamber

Very high precission of specimen movement, along X, Y

and Z direction (up to 1µm). Very high stabilisation is

necessaryAdditionally mounted equipment:

- Goniometer – allows specimen tilting and rotation

- Heating device – on line structure observation during

heating time

- Cooling device – used for biological specimens and

protections against contamination – liquid nitrogen is

applied

- X-ray, EELS or Auger spectrometers (STEM)

Слайд 25Contamination

Negative phenomenon – the rest of silicon oil

vapeurs deriving from cacuum pumps are sedimented on the specimen

surface and borders of apertures. This phenomenon can heavy decrease contrast and resolution of images.Protection:

Instalation of anti contamination device inside TEM column – i.e. ring or „cold fingers” sourrounded specimen - cooled by liquid nitrogene

Increasing of vacuum quality by application „Cold Trap” and „oil free” pomps like: Ion Getter Pump (IGP) or Turbo Molecular Pump (TMP).

Слайд 29Vacuum system

Vacuum is necessary that gas molecules do not interfere

with the course of the electron beam

Necessary condition: high vacuum

(10-4 - 10-5 Pa),Vaccum is obtained by the system of rotary (RP) and oil diffusion pomps (DP) or TMP or IGP.

Turbo Molecular Pumps (TMP) and Ion Getter Pumps (IGP) don’t contain oilacji)

The lock is used to paste samples into specimen chamber without column aeration

Слайд 32Vacuum system – diffusion pump

Reached vacuum:

10-5 Pa

Initial vacuum 10-2 Pa

produced by rotary pump is

absolutely necessary

Слайд 33Vacuum system – Ion Getter Pump

Gas molecules

are ionised by high voltage (5kV)

and absorbed

by the spongy surface of the titanium cathodB There is no phenomenon of contamination

Слайд 34Vacuum system –

Turbo Molecular Pump

It works on the

principle of centrifugal pump.

Thanks generated by the rotary

pump an initial vacuum, the turbine can reach very high ultrasonic speeds. This causes the mechanical expulsion of the gas molecules.

There is no phenomenon of contamination.

Слайд 35Penning vacuum gauge

Vacuum glow gauge

The measure is the current vacuum

glow discharge

Electrodes are placed in the external permanent magnet, it

prevents stalling discharge.Electrode head is applied high voltage (1000 - 2000V).

Is used in the pressure range from approx. 10-2 do 10-7 Pa

Слайд 37Pirani vacuum gauge

Vacuum thermal-conductive gauge.

The special wire end located in

the vacuum test is heated by electric current

When the vacuum

is better, the worse the heat is extracted from the wire, which increases its temperature. As a result, the wire resistance is increased.applies to vacuum measurement in the range from 0,5 up to 10-3 Pa.

Слайд 38Lens system forming image

Typically it consists of three, four or

five lenses:

Obiective Lens - OL

Intermediate lens - IL (one or

two)Projection lens - PL, (one or two)

Слайд 39Obiective lens

The lens of the greatest importance

Generates a first image

(original image)

In the back focal plane image is created diffraction

It

has the shortest focal length possible, to minimize spherical aberration coefficientIt comprises a device for correction of astigmatism

Слайд 40Obiective aperture

Improves contrast of final image

By changing the position of

this aperture we can get different types of images

Слайд 41Intermediate Lens

It enables to obtain:

magnification of initial image

diffraction pattern of

the selected area SAED

Слайд 44Registration of images

Visualization of the images is on the screen

coated with phosphor

The electrons falling on the screen, causing the

emission of photons of visible light and allow visual observation of imagesRegistration of images is possible on films or digital circuits CCD

Слайд 47Power Supply

To ensure production of appropriate voltages used for:

cathode

heating, accelerating movement of electrons,

excitation systems of lenses

powering auxiliary

systemСлайд 53Scanning Transmission Microscope - STEM

Transmission electron microscope equipped with a

transmission detector further analyzes the passing electrons.

In STEM may also

include other detectors typical for SEM like: SE, BSE and X-rayAdvantages:

opportunity to observe specimens thicker than in the TEM

possibility to perform microanalysis by EDS or EELS

Слайд 55HVTEM / HRTEM

HVTEM – High Voltage TEM

HRTEM – High

Resolution TEM

Used for studies crystalline samples

It enables observation of atoms

and atomic planesZoom up to several million times

It enables observation of crystal structure, crystal defects, the interphase boundaries.

It enables testing of thicker samples

Слайд 59HVHRTEM

Atomic resolution:

Grain boundaries orientation

Interphase boundaries, subgrains, stacking faults, t

microtwins, polytype structure

Defects of atoms distribution inside crystallline and amorphous

phasesGold particle on carbon film

Слайд 60EDS – X-ray radiation

X-ray - formed in the electron

beam column takes an electron from an inner shell of

the atom in the test sample. His place is taken by an electron from a higher energy shell emitting quantum characteristic energyThe radiation energy is characteristic of the element

Possible chemical composition - microanalysis (detection of elements)

Слайд 62EELS –

Electron Energy Loss Spectroscopy

Spectroscopy (EELS) - is based

on the analysis of the energy distribution of scattered electrons.

With such a collision the electron loses some part of their kinetic energy - the energy of the primary electrons E0 is reduced by the value characteristic for the materialIt is possible microanalysis chemical composition.

The EELS spectrometer is placed under the screen

Слайд 66Selected Area Electron Diffraction

The need to remove the contrast aperture

Changing

the current excitation of the intermediate and projection lenses

Introduction selection

aperture - SAСлайд 67Diffraction image formation

Mikrodiffraction

(SAED – selected area electron diffraction )

– minimal diameter of diffraction surface is 1μm

Nanodiffraction

(CBED – convergent

beam electron

diffraction)

– diameter of

diffraction surface is

less than 100nmСлайд 68Electron Diffraction – Bragg’s model

Bragg’s condition for electron beam

diffraction

nλ=2dsinθ

During the interaction of the electron

beam with a sample of the crystalline structure, below the sample is receive the primary beam and the diffracted beams as much as lattice planes with various plane indices hkl satisfies the Bragg equationСлайд 69Geometry of electron diffraction in TEM

Location reflections with respect to

the central point indicates the orientation reflected planes (hkl) -

vectors connecting track beam indomitable successive reflections are perpendicular to the planes, and their length is inversely proportional to the spacingsr = L ·tg2θ

r = L·λ/d

λL – constant of microscope

Слайд 70Interpretation of electron diffraction patterns

Identification of the structure of the

investigated crystal from which the reflections were formed

Indexing (specify indexes

of atom planes)Crystallographic analysis based on the diffraction image (SAED)

Applying the structure of the sample on the basis of the shape of elementary lattice and intensity of reflections

Слайд 71Application of electron diffraction in materials investigation

Diffraction studies enable the

identification of the observed phase

Identification of a polycrystal on the

basis of the diffraction pattern is compared with the calculated measurement of the interplanar spacings with values contained in the databases of crystallographic data and determining the indices indices of {hkl} atom planes forming a diffraction patternIn the case of a single crystal identification is a comprehensive solution diffraction pattern - defining indexes of atomic planes (hkl), zone axis [uvw] and their mutual crystallographic orientation

Слайд 74Imperfections in the crystal structure (dislocations and grain boundary between

the two polycrystal).

Image obtained by TEM.

Слайд 81Literatura

G. Schimmel, Metodyka mikroskopii elektronowej, PWN, Warszawa 1976

Ian M. Wat,

The principles and practice of electron microscopy, second edition, Cambridge

University Press, 1997Peter J. Goodhew, John Humphreys, Richard Beanland, Electron microscophy and analysis, third edition, Taylor & Francis Inc, London 2001

Andrzej Barbacki, Mikroskopia elektronowa, Wydawnictwo Politechniki Poznańskiej, Poznań 2005

Leszek A. Dobrzański, Eugeniusz Hajduczek, Mikroskopia świetlna i elektronowa, Wydawnictwa Naukowo-Techniczne, Warszawa 1987

Pod red. W. Dudzińskiego, Materiały konstrukcyjne w budowie maszyn, Oficyna Wydawnicza Politechniki Wrocławskiej, Wrocław 1994

Jan Kozubowski, Metody transmisyjnej mikroskopii elektronowej, Wydawnictwo Śląsk, Katowice 1975

Ludwig Reimer, Transmission Electron Microscopy, Spinger Verlag, Berlin-Heidelberg-New York-Tokyo 1984