Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

UNCONVENTIONAL HYDROCARBONS

Содержание

- 1. UNCONVENTIONAL HYDROCARBONS

- 2. Conventional and unconventionalConventional and unconventional oil and

- 3. Unconventional hydrocarbon includes:Shale gas and oilTight gas

- 4. Because of technological advancements such as horizontal

- 5. Shale gasShale gas is natural gas locked in

- 6. The gas remaining in these shale is

- 7. Shale oil is oil locked in shales and

- 8. ExtractionThe gas deposits are usually found in

- 9. TWO MAJOR DRILLING TECHNIQUES ARE USED TO

- 10. HEAVY OIL AND TAR SAND

- 11. Oil sands, tar sands, crude bitumen, or more technically bituminous

- 12. INTRODUCTIONKnown for a long time and was

- 13. Natural bitumen deposits are reported in many

- 14. Tar sand contains asphaltic oil rich in

- 15. METHODS OF EXTRACTIONShallow reserves, which make up

- 16. Conditioning (подготовка) starts the process of separating sand

- 17. Deeply deposited bitumen reserves aren't reachable through

- 18. GAS HYDRATES

- 19. Gas Hydrates are compounds where methane (CH4)

- 20. Gas hydrates, or methane hydrates, are created when methane is

- 21. The source of the methane is mostly

- 22. Hydrate deposits generally occur in two types of

- 23. Слайд 23

- 24. Hydrates can be recovered in the following

- 25. COALBED METHANE

- 26. Coalbed natural gas (CBNG)Coalbed methane (CBM or coal-bed methane), coalbed gas, coal

- 27. CBM can be recovered from underground coal before, during,

- 28. 1 236745Name all the unconventional hydrocarbons

- 29. Слайд 29

- 30. Скачать презентанцию

Слайды и текст этой презентации

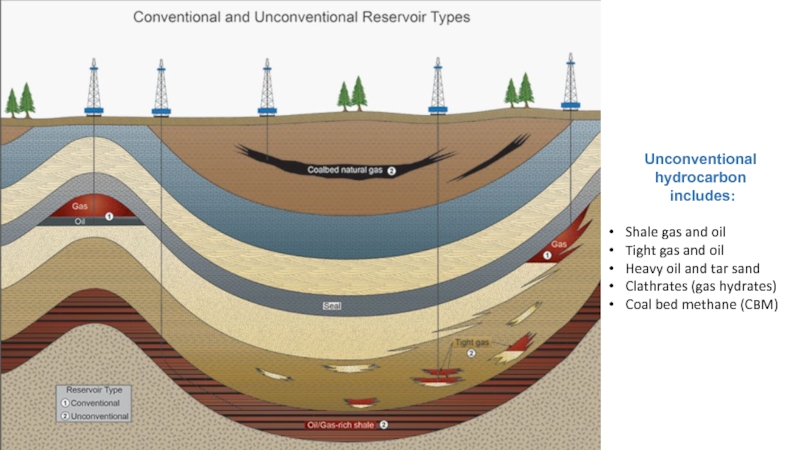

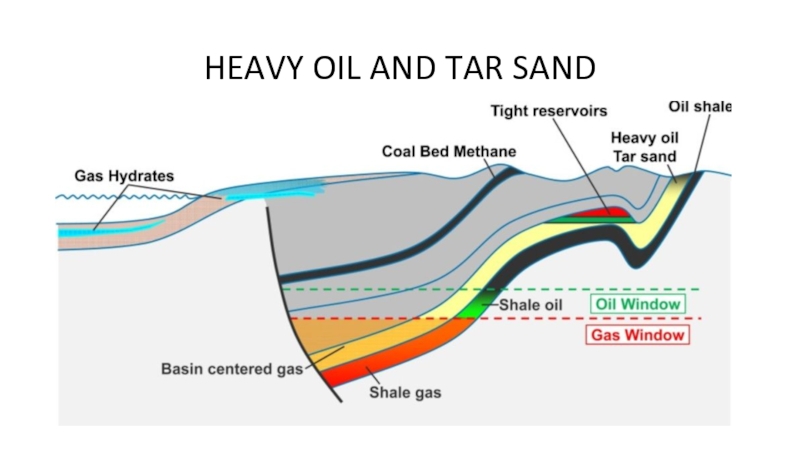

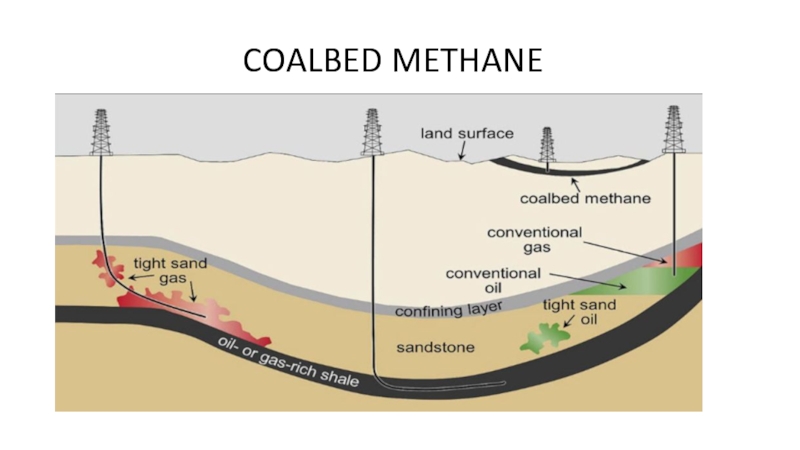

Слайд 3Unconventional hydrocarbon

includes:

Shale gas and oil

Tight gas and oil

Heavy oil

and tar sand

Clathrates (gas hydrates)

Coal bed methane (CBM)

Слайд 4Because of technological advancements such as horizontal drilling and hydraulic

fracturing, these previously uneconomical resources are the focus of new

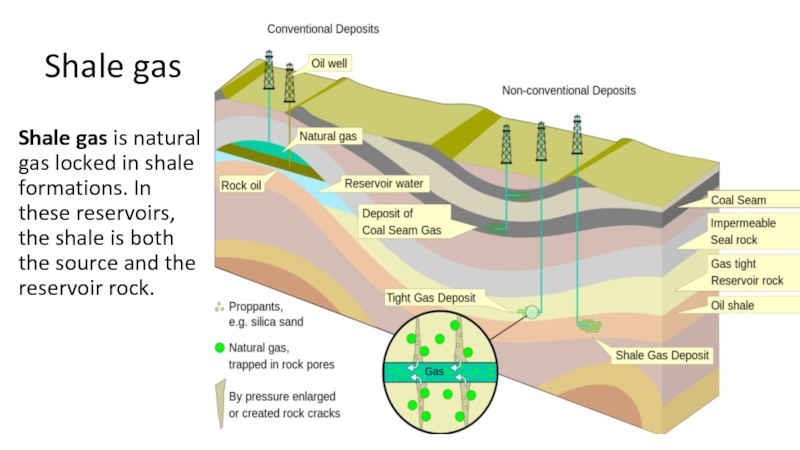

oil and gas exploration and development. In general, exploration geologists and engineers attempt to locate hydrocarbon reservoirs that will be productive and profitable.Слайд 5Shale gas

Shale gas is natural gas locked in shale formations. In

these reservoirs, the shale is both the source and the

reservoir rock.Слайд 6The gas remaining in these shale is present in very

small pores and may also be partly adsorbed on remaining

organic matter or its residue (coke) and on clay minerals.The shales have been uplifted and may therefore have small extensional fractures, but they must be hydro fractured by water injection to increase the permeability.

Слайд 7Shale oil is oil locked in shales and associated tight siltstones

or carbonates, all of which have low permeability and porosity.

(should not be confused with oil shale)Tight gas and oil reservoirs contain natural gas and oil trapped in the pores of siltstones and sandstones with very low permeability (<0.1 millidarcy) and very low porosity (<10%).

Слайд 8Extraction

The gas deposits are usually found in rocks that have

low permeability, ruling out the possibility of regular drilling.

The most commonly used method is called fracking (hydraulic fracturing). As opposed to vertical drilling for traditional gas, in this case horizontal drilling is carried out.

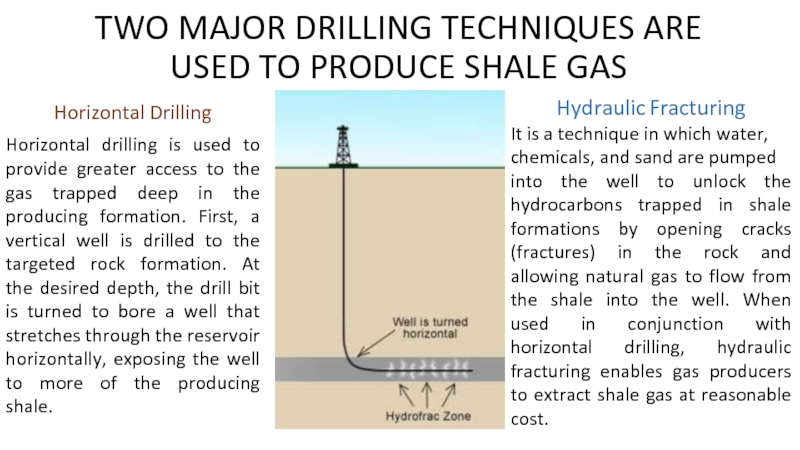

Слайд 9TWO MAJOR DRILLING TECHNIQUES ARE USED TO PRODUCE SHALE GAS

Horizontal Drilling

Horizontal drilling is used to provide greater access to

the gas trapped deep in the producing formation. First, a vertical well is drilled to the targeted rock formation. At the desired depth, the drill bit is turned to bore a well that stretches through the reservoir horizontally, exposing the well to more of the producing shale. Hydraulic Fracturing

It is a technique in which water,

chemicals, and sand are pumped

into the well to unlock the hydrocarbons trapped in shale formations by opening cracks (fractures) in the rock and allowing natural gas to flow from the shale into the well. When used in conjunction with horizontal drilling, hydraulic fracturing enables gas producers to extract shale gas at reasonable cost.

Слайд 11Oil sands, tar sands, crude bitumen, or more technically bituminous sands, are either

loose sands or partially consolidated sandstone containing a naturally occurring

mixture of sand, clay, and water, saturated with a dense and extremely viscous form of petroleum technically referred to as bitumen (or colloquially as tar due to its superficially similar appearance). The oil sands have long been referred to as tar sands; however, industry groups dispute this name due to its negative environmental associations.Слайд 12INTRODUCTION

Known for a long time and was easy to exploit

for use in small quantities.

In southern California oil was

mined from the early 1860s to the 1890s because the heavy oil would not flow to the wells. Tar sands are sandstone reservoirs which have been filled with oil at shallow depth <2 km (<70-80 C) so that the oil has become biodegraded. Reservoir rocks which have been buried more deeply and then uplifted before the oil migration may be sterilized at higher temperatures and are less likely to be biodegraded.

Слайд 13Natural bitumen deposits are reported in many countries, but in

particular are found in extremely large quantities in Canada. Other large reserves

are located in Kazakhstan, Russia, and Venezuela. The estimated worldwide deposits of oil are more than 2 trillion barrels (320 billion cubic meters).Слайд 14Tar sand contains asphaltic oil rich in asphaltenes and resins.

It has a high content of aromatics and naphthenes compared

to paraffins, and a high content of nitrogen, sulphur and oxygen (NSO).Most of the hydrocarbon molecules have more than 60 carbon atoms and the boiling point and viscosity are therefore very high.

The viscosity of the biodegraded oil is very high and the oil must be heated so that the viscosity is reduced before it can be produced by drilling wells.

Tar sandstone

Слайд 15METHODS OF EXTRACTION

Shallow reserves, which make up about 20 percent

of oil sands, are recovered through surface mining (ex-situ), which is

mining through open pits.The process of surface mining differs a bit from company to company but generally includes conditioning, separation and froth treatment.

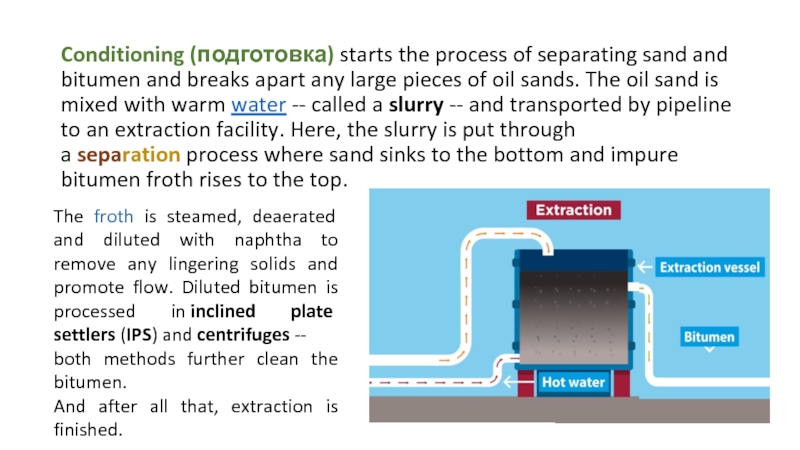

Слайд 16Conditioning (подготовка) starts the process of separating sand and bitumen and

breaks apart any large pieces of oil sands. The oil

sand is mixed with warm water -- called a slurry -- and transported by pipeline to an extraction facility. Here, the slurry is put through a separation process where sand sinks to the bottom and impure bitumen froth rises to the top.The froth is steamed, deaerated and diluted with naphtha to remove any lingering solids and promote flow. Diluted bitumen is processed in inclined plate settlers (IPS) and centrifuges --

both methods further clean the bitumen.

And after all that, extraction is finished.

Слайд 17Deeply deposited bitumen reserves aren't reachable through open-pit digging and

are recovered using in situ techniques, the most successful known as SAG-D. SAG-D is steam-assisted

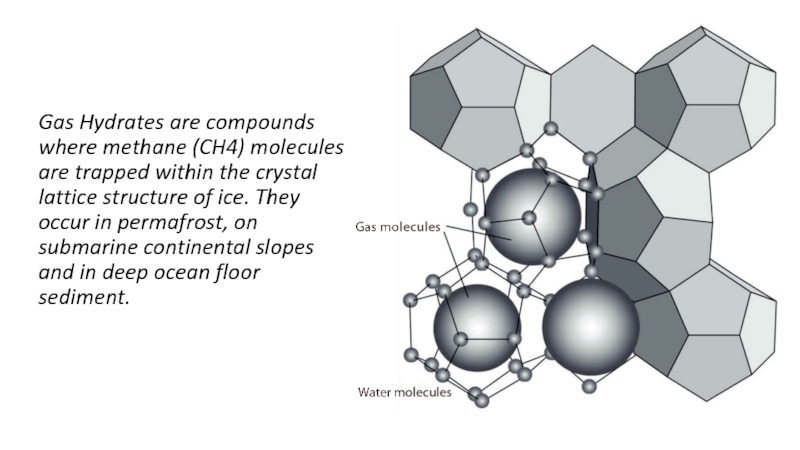

gravity drainage, a method that involves injecting steam into wells within the oil sand. The intense temperature and pressure separate the bitumen and water from the sand, and the bitumen -- rendered soft with the heat -- surfaces while the sand stays put. Other in situ techniques include toe to heel air injection (THAI), a relatively new process that combines both vertical and horizontal air injections into underground wells, and a vapor extraction process (VAPEX), similar to SAG-D but with a solvent injections instead of steam.Слайд 19Gas Hydrates are compounds where methane (CH4) molecules are trapped

within the crystal lattice structure of ice. They occur in

permafrost, on submarine continental slopes and in deep ocean floor sediment.Слайд 20Gas hydrates, or methane hydrates, are created when methane is frozen in the molecular structure

of ice. They are classified as clathrates, compounds formed by the

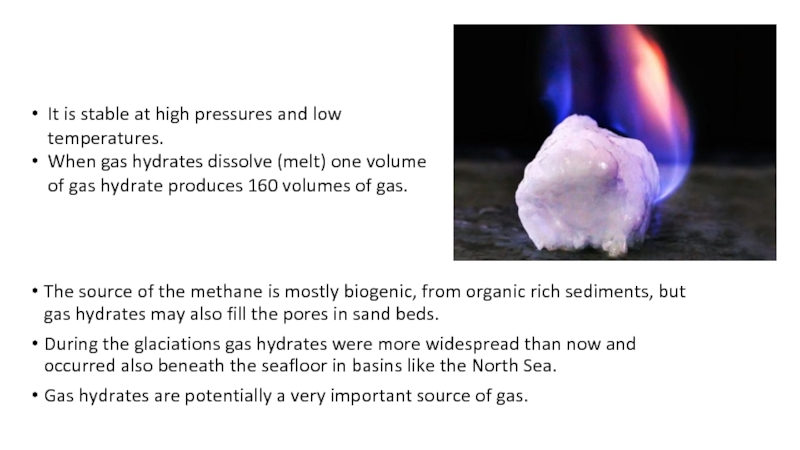

inclusion of one molecule within cavities in the crystal lattice of another. A unique property of clathrates is the absence of chemical bonding, which makes it possible to separate them relatively easily. When methane hydrates are warmed or depressurized, it will revert back to water and natural gas.Слайд 21The source of the methane is mostly biogenic, from organic

rich sediments, but gas hydrates may also fill the pores

in sand beds.During the glaciations gas hydrates were more widespread than now and occurred also beneath the seafloor in basins like the North Sea.

Gas hydrates are potentially a very important source of gas.

It is stable at high pressures and low temperatures.

When gas hydrates dissolve (melt) one volume of gas hydrate produces 160 volumes of gas.

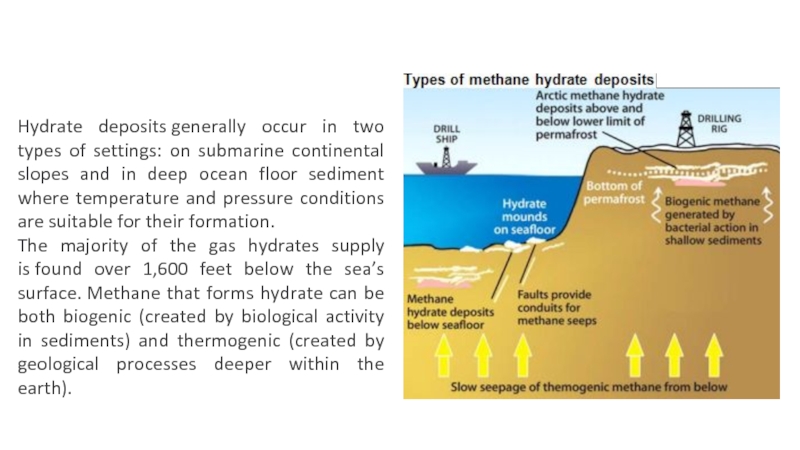

Слайд 22Hydrate deposits generally occur in two types of settings: on submarine

continental slopes and in deep ocean floor sediment where temperature

and pressure conditions are suitable for their formation.The majority of the gas hydrates supply is found over 1,600 feet below the sea’s surface. Methane that forms hydrate can be both biogenic (created by biological activity in sediments) and thermogenic (created by geological processes deeper within the earth).

Слайд 24Hydrates can be recovered in the following ways:

Heating the hydrates

using hot water, steam, electromagnetic radiation (such as microwaves) or

electricity. These methods would raise the temperature so that the hydrates would melt, releasing the natural gas.Lowering the pressure of the hydrates. Lowering the pressure would also cause the hydrates to melt, releasing the natural gas.

Injecting chemical inhibitors. Inhibitors prevent hydrates from forming or cause hydrates that have formed to “melt.”

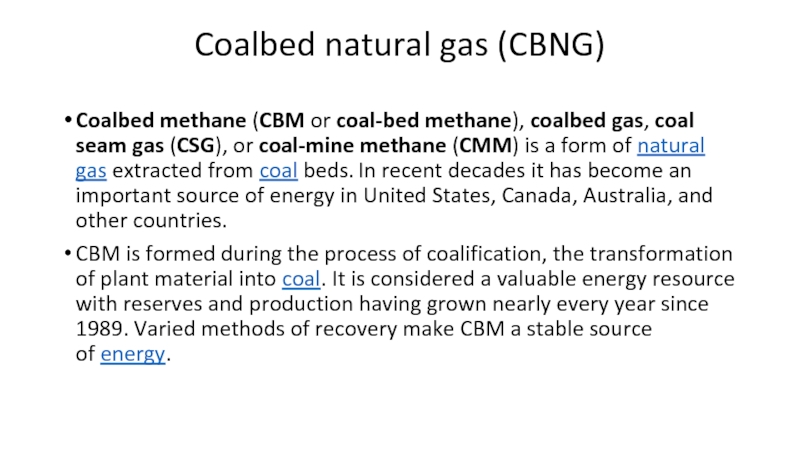

Слайд 26Coalbed natural gas (CBNG)

Coalbed methane (CBM or coal-bed methane), coalbed gas, coal seam gas (CSG), or coal-mine

methane (CMM) is a form of natural gas extracted from coal beds. In recent decades it

has become an important source of energy in United States, Canada, Australia, and other countries.CBM is formed during the process of coalification, the transformation of plant material into coal. It is considered a valuable energy resource with reserves and production having grown nearly every year since 1989. Varied methods of recovery make CBM a stable source of energy.