Разделы презентаций

- Разное

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

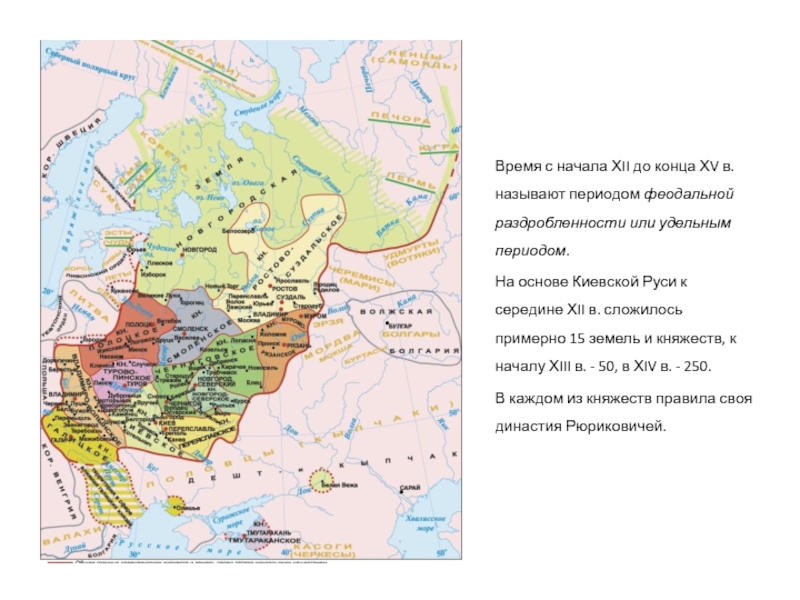

- История

- Литература

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

LECTURE № 13 CORROSION 15.04.2015

Содержание

- 1. LECTURE № 13 CORROSION 15.04.2015

- 2. Corrosion is the gradual destruction of materials

- 3. Corrosion can also occur in materials other

- 4. Many structural alloys corrode merely from exposure

- 5. Metal corrosion is a spontaneous thermodynamic destruction

- 6. In terms of redox reactions: nature of

- 7. Iron oxidation by atmospheric oxygen:4Fe + 3O2

- 8. Steel Corrosion 1) Initial Oxidation Reaction: 2) Secondary Oxidation Reaction:rust

- 9. Classification of CorrosionBy type of corrosive environmentBy

- 10. By operating conditions known the following types

- 11. Crevice corrosion - electrochemical corrosion in cracks

- 12. Gas corrosion Atmospheric corrosionLiquid corrosionSoil corrosionStray currents

- 13. Gas Corrosion - chemical corrosion of metals

- 14. Continual CorrosionUniform corrosionUneven corrosion

- 15. Local corrosionBy ulcers By pointsBy spots

- 16. Causes of localized corrosionIntergranual corrosionSea waterRoad salt

- 17. CHEMICAL CORROSIONis the interaction of the metal

- 18. 1. Oxidation corrosion(Reaction with oxygen) Some of the

- 19. During oxidation of a metal, metal

- 20. Oxides of Pb, Al and Sn are

- 21. 2. Corrosion by other gases (Cl2,

- 22. 3. Liquid - metal corrosion In several industries,

- 23. ELECTROCHEMICAL CORROSION is anodic oxidation of the

- 24. Oxidation of anodic part takes place and

- 25. Mechanism: Electrochemical corrosion involves the flow of electron

- 26. Thus, electrochemical corrosion occurs:where a conducting liquid

- 27. Oxygen reduction (acidic medium pH

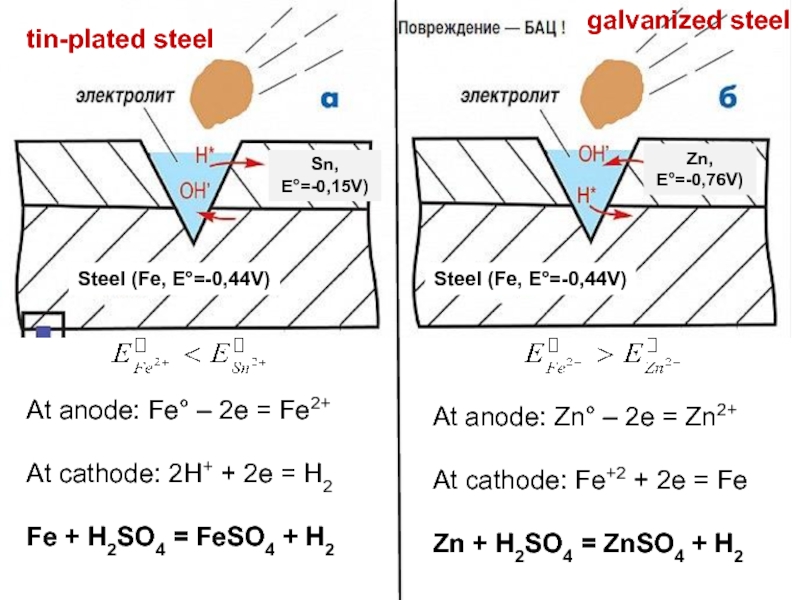

- 28. Steel (Fe, E=-0,44V)Steel (Fe, E=-0,44V)Zn, E=-0,76V)Sn, E=-0,15V)tin-plated

- 29. Factors Influencing Corrosion The nature and extent of

- 30. 1. The position of metals in the

- 31. potential area where any corrosion impossible, example

- 32. Affecting Nature of the Corroding EnvironmentTemperature: Corrosion

- 33. Group 1 - alkali metals - the

- 34. Group 3 - Aluminium - forming stable

- 35. 5,6,7,8 group - by metals of subgroups

- 36. PROTECTION METHODSMaterial selectionImprovements in materialDesign of structuresAlteration of environmentAdd inhibitorsGalvanic Cathodic or Anodic protectionActive electrochemical protectionCoatings

- 37. Слайд 37

- 38. Make sure you thoroughly understand the following

- 39. Скачать презентанцию

Слайды и текст этой презентации

Слайд 2 Corrosion is the gradual destruction of materials (usually metals) by

chemical reaction with their environment.

the word, this means electrochemical oxidation of metals in reaction with an oxidants such as oxygen. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal.Слайд 3 Corrosion can also occur in materials other than metals, such

as ceramics or polymers, although in this context, the term

degradation is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases.Слайд 4 Many structural alloys corrode merely from exposure to moisture in

air, but the process can be strongly affected by exposure

to certain substances. Corrosion can be concentrated locally to form a pit or crack, or it can extend across a wide area more or less uniformly corroding the surface. Because corrosion is a diffusion-controlled process, it occurs on exposed surfaces. As a result, methods to reduce the activity of the exposed surface, such as passivation and chromate conversion, can increase a material's corrosion resistance. However, some corrosion mechanisms are less visible and less predictable.Слайд 5 Metal corrosion is a spontaneous thermodynamic destruction (anodic oxidation) metal

as a result of exposure to chemical and electrochemical environment,

it is heterogeneous redox process that occurs at the interface.Слайд 6 In terms of redox reactions: nature of this interaction is

reduced to the oxidation of the metal and restore oxidant.

When metal corrosion occur at its surface take place simultaneously two independent electrochemical reactions:at anode: Me - ne = Me+n

at cathode: Ox + ne = Red

Corrosive environment called surfactants, are present around the structural member, its impact on the material and cause it to corrode. Corrosive medium may be air, industrial atmosphere, gases, water, sea climate, land - soil, acids, alkalis, water and salt solutions.

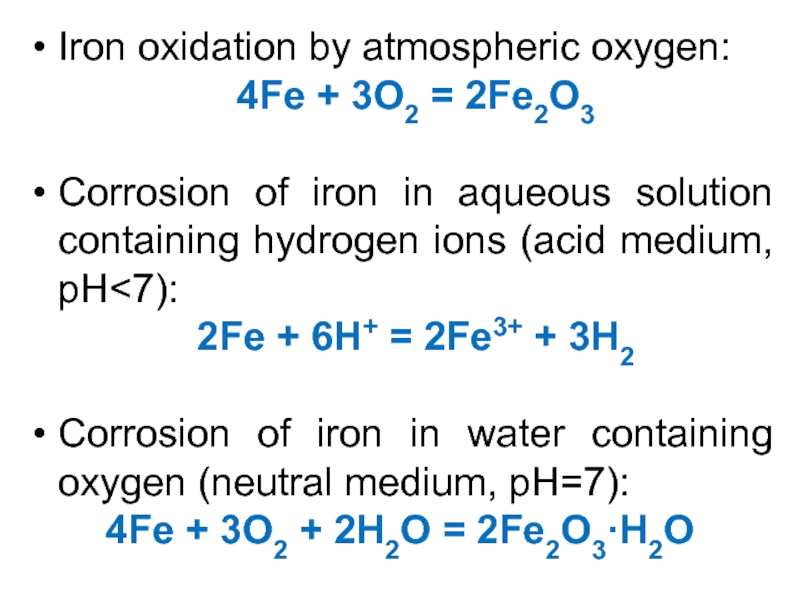

Слайд 7Iron oxidation by atmospheric oxygen:

4Fe + 3O2 = 2Fe2O3

Corrosion

of iron in aqueous solution containing hydrogen ions (acid medium,

pH<7):2Fe + 6H+ = 2Fe3+ + 3H2

Corrosion of iron in water containing oxygen (neutral medium, pH=7):

4Fe + 3O2 + 2H2О = 2Fe2O3·H2О

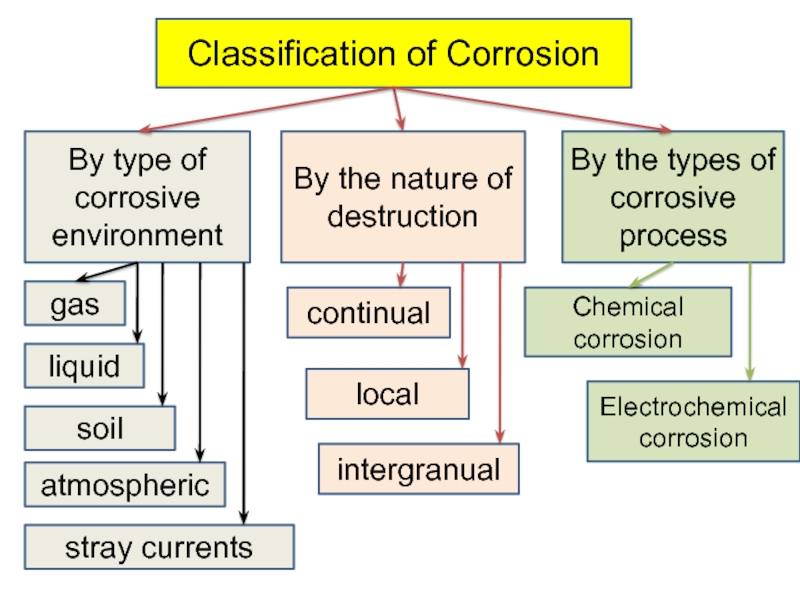

Слайд 9Classification of Corrosion

By type of corrosive environment

By the nature of

destruction

By

the types of corrosive process

Chemical corrosion

Electrochemical corrosion

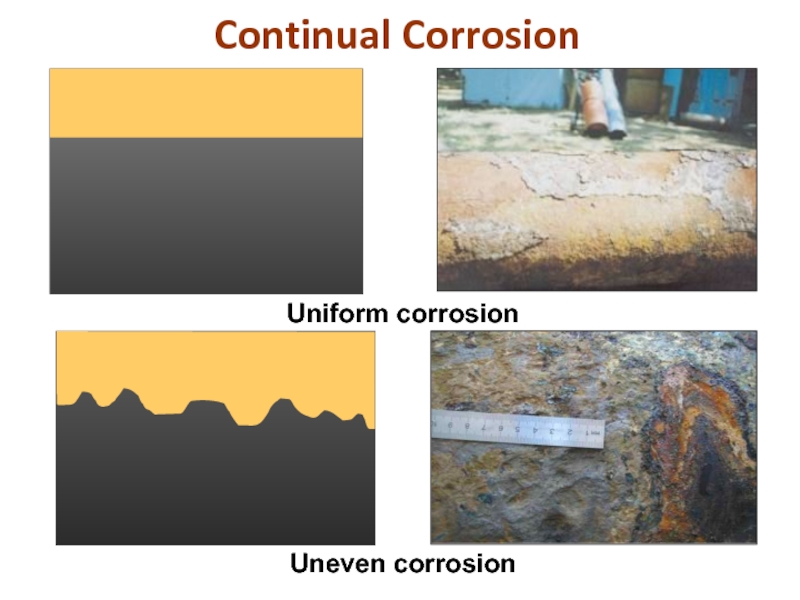

continual

local

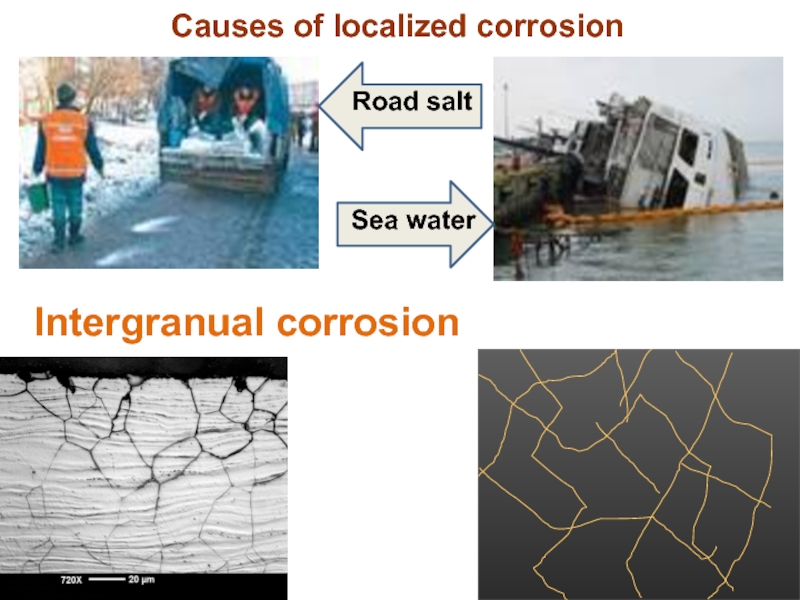

intergranual

gas

liquid

soil

atmospheric

stray currents

Слайд 10By operating conditions known the following types of electrochemical corrosion

crevice

corrosion

contact corrosion

corrosion fatigue

corrosion

cracking

Corrosion friction

(Fretting)

Corrosion in the collision

(Cavitation)

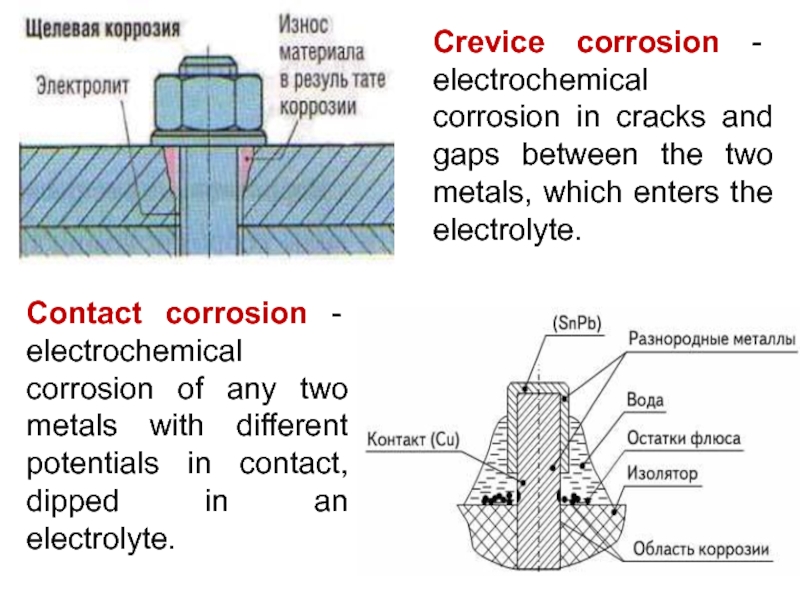

Слайд 11Crevice corrosion - electrochemical corrosion in cracks and gaps between

the two metals, which enters the electrolyte.

Contact corrosion - electrochemical

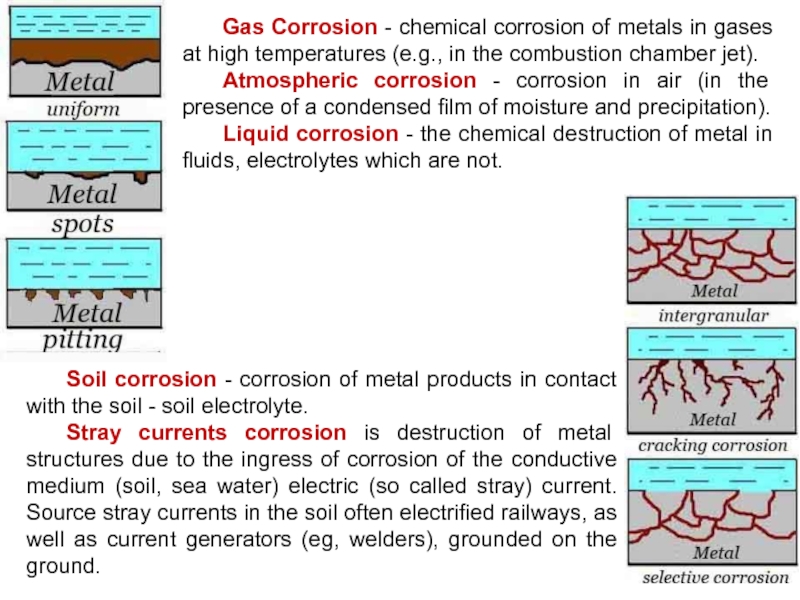

corrosion of any two metals with different potentials in contact, dipped in an electrolyte. Слайд 13 Gas Corrosion - chemical corrosion of metals in gases at

high temperatures (e.g., in the combustion chamber jet).

Atmospheric corrosion -

corrosion in air (in the presence of a condensed film of moisture and precipitation).Liquid corrosion - the chemical destruction of metal in fluids, electrolytes which are not.

Soil corrosion - corrosion of metal products in contact with the soil - soil electrolyte.

Stray currents corrosion is destruction of metal structures due to the ingress of corrosion of the conductive medium (soil, sea water) electric (so called stray) current. Source stray currents in the soil often electrified railways, as well as current generators (eg, welders), grounded on the ground.

Слайд 17CHEMICAL CORROSION

is the interaction of the metal with the environment

in which the oxidation of the metal and restoring the

oxidant corrosive environment occurs in one act without causing an electric current.This type of corrosion occurs due to direct chemical attack of environment or atmospheric gases like oxygen halogens, hydrogen sulphide, sulphur dioxide, nitrogen or anhydrous inorganic liquid with metal surfaces in immediate proximity.

Chemical corrosion is of three main types as:

Oxidation Corrosion (with Oxygen)

Corrosion by Other Gases

In non-electrolyte Liquid Metal Corrosion

Слайд 181. Oxidation corrosion

(Reaction with oxygen)

Some of the metals directly react

with oxygen in the absence of moisture:

Alkali and alkaline

earth metals react with oxygen at room temperature and form corresponding oxides, while some metals react with oxygen at higher temperature. Metals like Ag, Au and Pt are not oxidized as they are noble metals.

4Fe + 3О2 = 2Fe2О3

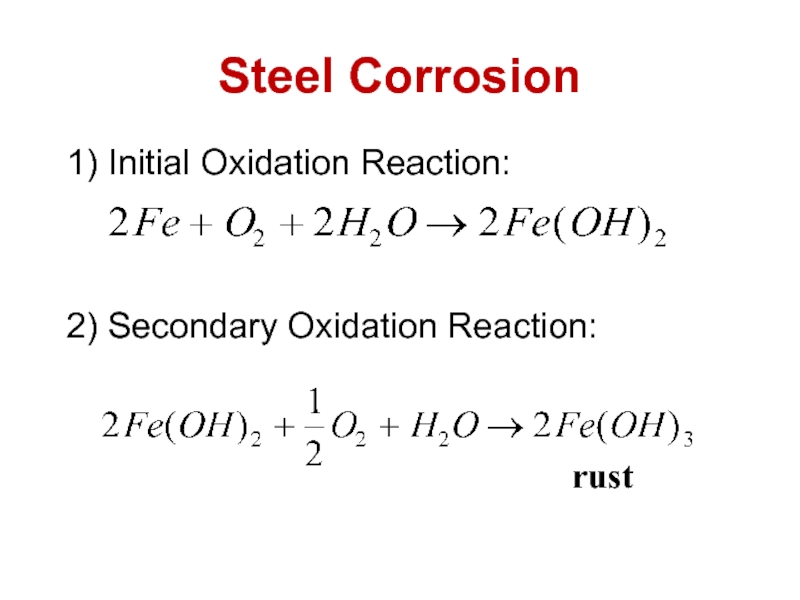

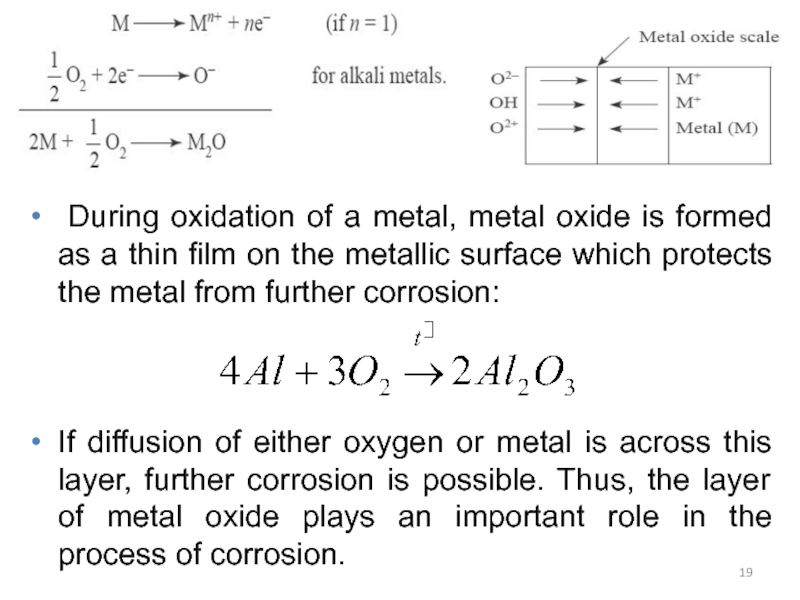

Слайд 19 During oxidation of a metal, metal oxide is formed

as a thin film on the metallic surface which protects

the metal from further corrosion:If diffusion of either oxygen or metal is across this layer, further corrosion is possible. Thus, the layer of metal oxide plays an important role in the process of corrosion.

Слайд 20Oxides of Pb, Al and Sn are stable and hence

inhibit further corrosion. They form a stable, tightly adhering oxide

film.In case of porous oxide film, atmospheric gases pass through the pores and react with the metal and the process of corrosion continues to occur till the entire metal is converted into oxide.

Porous oxide layer is formed by alkali and alkaline earth metals. Molybdenum forms a volatile oxide film of MoO3 which accelerates corrosion.

Au, Ag, Pt form unstable oxide layer which decomposes soon after the formation, thereby preventing further corrosion.

Слайд 212. Corrosion by other gases

(Cl2, SO2, H2S, NOx)

In dry

atmosphere, these gases react with metal and form corrosion products

which may be protective or non-protective.Dry Cl2 reacts with Ag and forms AgCl which is a protective layer, while SnCl4 is volatile.

In petroleum industries at high temperatures, H2S attacks steel forming FeS scale which is porous and interferes with normal operations.

2Fe + 3Cl2 = 2FeCl3

Слайд 223. Liquid - metal corrosion

In several industries, molten metal passes

through metallic pipes and causes corrosion due to dissolution or

due to internal penetration.For example:

liquid metal mercury dissolves most metals by forming amalgams, thereby corroding them.

In oil

In sulphur

In organic substances

Cu + S = CuS

2 Ag + S = Ag2S

2Al + 6ССl4 = 3C2Cl6 + 3AlCl3

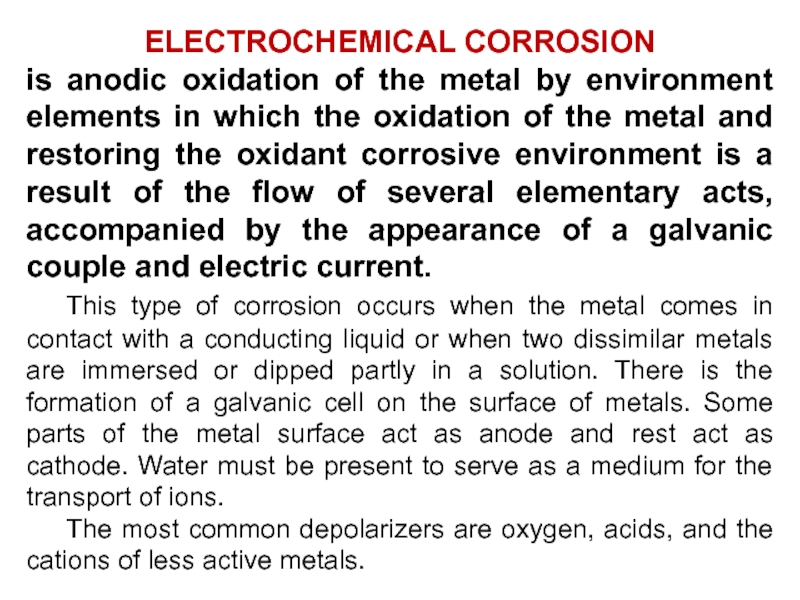

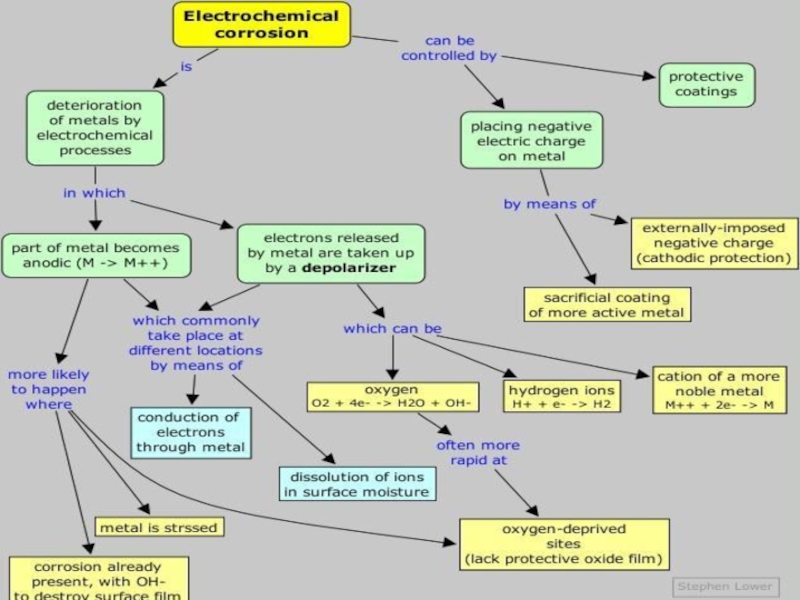

Слайд 23ELECTROCHEMICAL CORROSION

is anodic oxidation of the metal by environment

elements in which the oxidation of the metal and restoring

the oxidant corrosive environment is a result of the flow of several elementary acts, accompanied by the appearance of a galvanic couple and electric current.This type of corrosion occurs when the metal comes in contact with a conducting liquid or when two dissimilar metals are immersed or dipped partly in a solution. There is the formation of a galvanic cell on the surface of metals. Some parts of the metal surface act as anode and rest act as cathode. Water must be present to serve as a medium for the transport of ions.

The most common depolarizers are oxygen, acids, and the cations of less active metals.

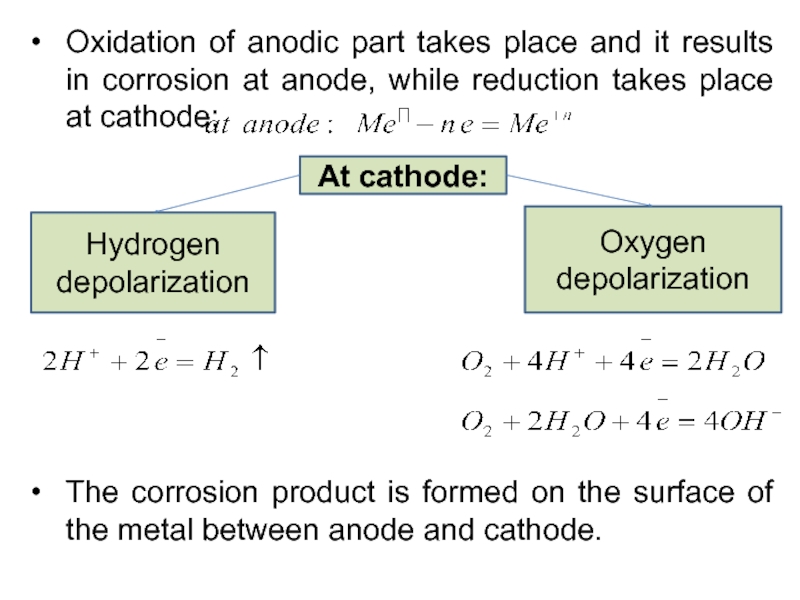

Слайд 24Oxidation of anodic part takes place and it results in

corrosion at anode, while reduction takes place at cathode:

The corrosion

product is formed on the surface of the metal between anode and cathode.At cathode:

Hydrogen depolarization

Oxygen depolarization

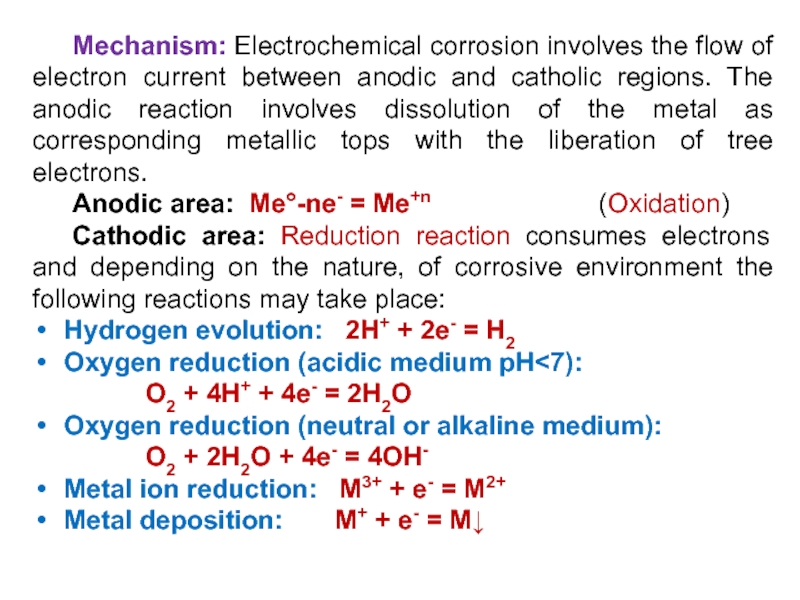

Слайд 25 Mechanism: Electrochemical corrosion involves the flow of electron current between anodic

and catholic regions. The anodic reaction involves dissolution of the

metal as corresponding metallic tops with the liberation of tree electrons.Anodic area: Me-ne- = Me+n (Oxidation)

Cathodic area: Reduction reaction consumes electrons and depending on the nature, of corrosive environment the following reactions may take place:

Hydrogen evolution: 2H+ + 2e- = H2

Oxygen reduction (acidic medium pH<7):

O2 + 4H+ + 4e- = 2H2O

Oxygen reduction (neutral or alkaline medium):

O2 + 2H2O + 4e- = 4OH-

Metal ion reduction: M3+ + e- = M2+

Metal deposition: M+ + e- = M

Слайд 26 Thus, electrochemical corrosion occurs:

where a conducting liquid (water, acid, salt

solutions) is in contact with a metal or

when two dissimilar,

metals or alloys are either immersed or dipped partially in a aqueous solution.In electrochemical or wet corrosion the following observations are made:

Formation of anodic and catholic part or parts in contact with each, other.

Presence of conducting medium

Corrosion of anodic areas only.

Formation of corrosion product between anodic and catholic areas.

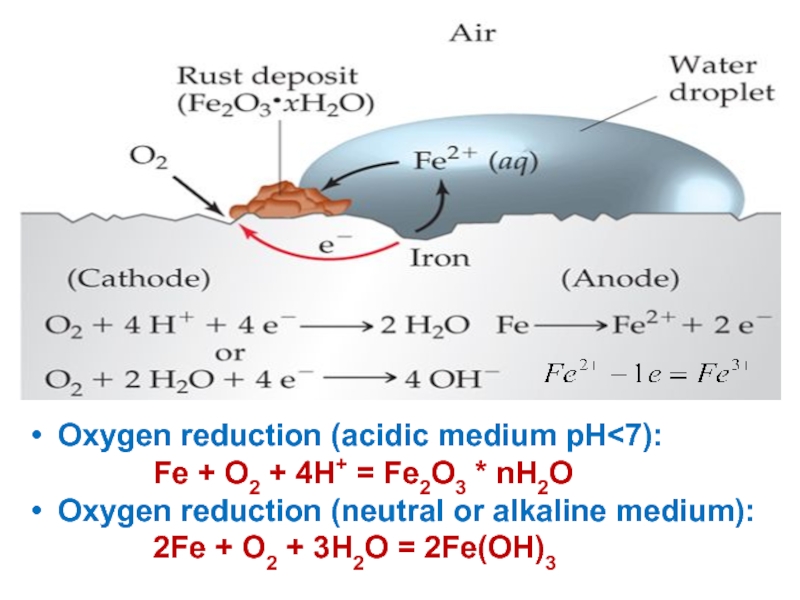

Слайд 27Oxygen reduction (acidic medium pH

* nH2O

Oxygen reduction (neutral or alkaline medium):

2Fe + O2 +

3H2O = 2Fe(OH)3 Слайд 28Steel (Fe, E=-0,44V)

Steel (Fe, E=-0,44V)

Zn,

E=-0,76V)

Sn,

E=-0,15V)

tin-plated steel

At anode: Fe

– 2e = Fe2+

At cathode: 2H+ + 2e

= H2Fe + H2SO4 = FeSO4 + H2

galvanized steel

At anode: Zn – 2e = Zn2+

At cathode: Fe+2 + 2e = Fe

Zn + H2SO4 = ZnSO4 + H2

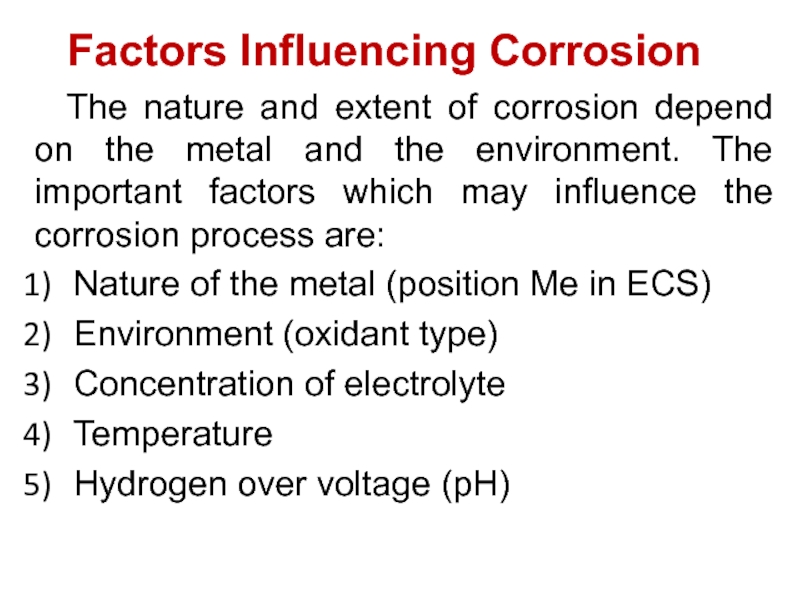

Слайд 29Factors Influencing Corrosion

The nature and extent of corrosion depend on

the metal and the environment. The important factors which may

influence the corrosion process are:Nature of the metal (position Me in ECS)

Environment (oxidant type)

Concentration of electrolyte

Temperature

Hydrogen over voltage (pH)

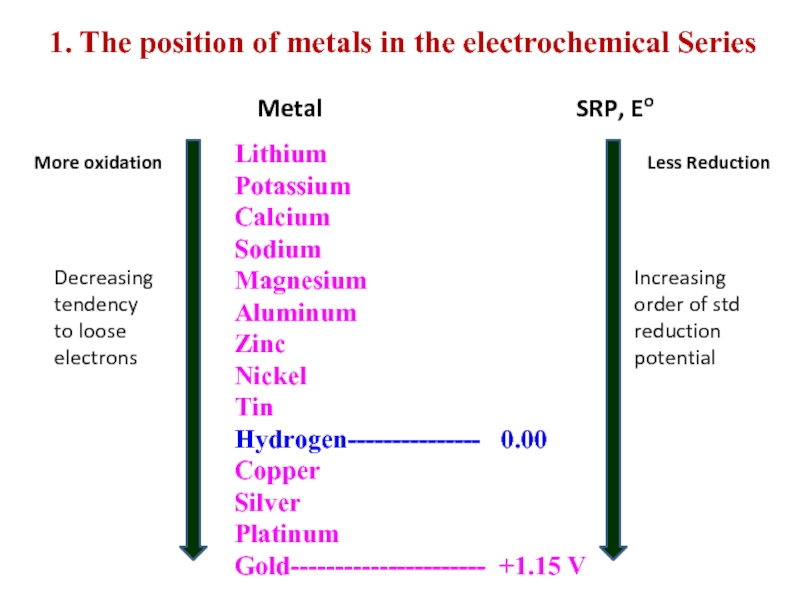

Слайд 301. The position of metals in the electrochemical Series

Lithium

Potassium

Calcium

Sodium

Magnesium

Aluminum

Zinc

Nickel

Tin

Hydrogen---------------

0.00

Copper

Silver

Platinum

Gold---------------------- +1.15 V

Metal

SRP, EoDecreasing tendency

to loose

electrons

Increasing order of std reduction potential

Less Reduction

More oxidation

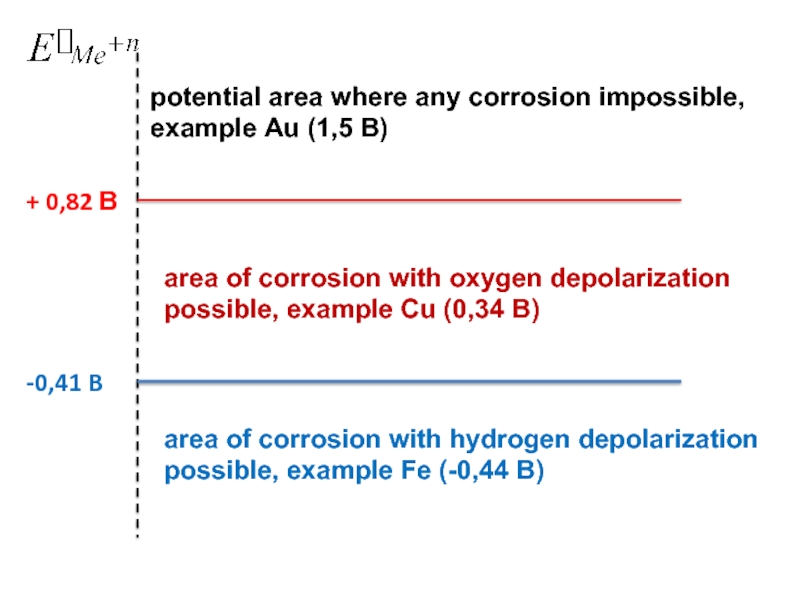

Слайд 31potential area where any corrosion impossible, example Аu (1,5 В)

area

of corrosion with oxygen depolarization possible, example Cu (0,34 В)

area

of corrosion with hydrogen depolarization possible, example Fe (-0,44 B) -0,41 B

+ 0,82 В

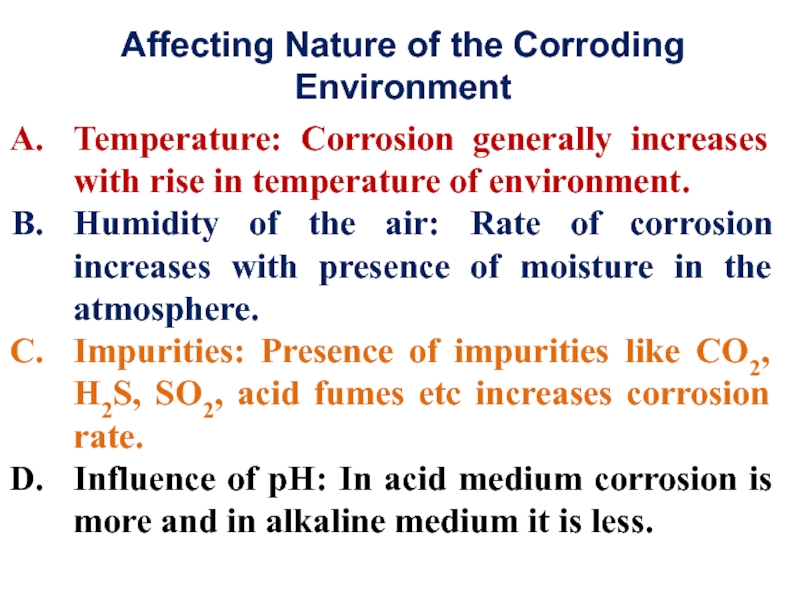

Слайд 32Affecting Nature of the Corroding Environment

Temperature: Corrosion generally increases with

rise in temperature of environment.

Humidity of the air: Rate

of corrosion increases with presence of moisture in the atmosphere.Impurities: Presence of impurities like CO2, H2S, SO2, acid fumes etc increases corrosion rate.

Influence of pH: In acid medium corrosion is more and in alkaline medium it is less.

Слайд 33Group 1 - alkali metals - the lowest corrosion resistance

1

group of the sub-groups - very resistant metals

Group 2 –

are unstable,Group 2 sub-groups – are more stable (in the presence of oxygen to form a strong oxide film protecting from further destruction)

corrosion properties of metals

Слайд 34Group 3 - Aluminium - forming stable oxide film (but

it is destroyed in solutions of acids and bases). In

concentrated nitric and sulfuric acids passivated aluminum.Group 4 – tin (Sn) and lead (Pb) – corrosion-resistant metals, thanks to strong oxide film.

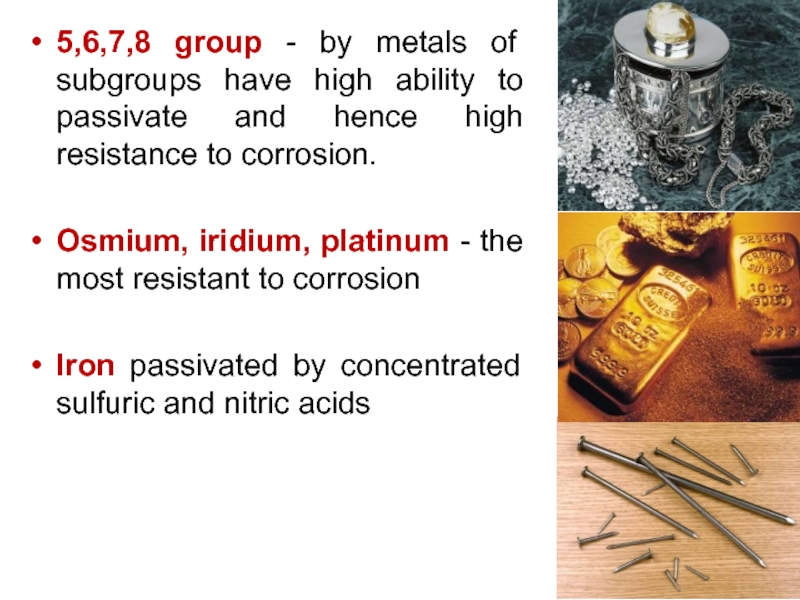

Слайд 355,6,7,8 group - by metals of subgroups have high ability

to passivate and hence high resistance to corrosion.

Osmium, iridium, platinum

- the most resistant to corrosionIron passivated by concentrated sulfuric and nitric acids

Слайд 36PROTECTION METHODS

Material selection

Improvements in material

Design of structures

Alteration of environment

Add inhibitors

Galvanic

Cathodic or Anodic protection

Active electrochemical protection

Coatings

Слайд 38 Make sure you thoroughly understand the following essential ideas which

have been presented above. It is especially imortant that you

know the precise meanings of all the highlighted terms in the context of this topic.Electrochemical corrosion of metals occurs when electrons from atoms at the surface of the metal are transferred to a suitable electron acceptor or depolarizer. Water must be present to serve as a medium for the transport of ions.

The most common depolarizers are oxygen, acids, and the cations of less active metals.

Because the electrons flow through the metallic object itself, the anodic and cathodic regions (the two halves of the electrochemical cell) can be at widely separated locations.

Anodic regions tend to develop at locations where the metal is stressed or is protected from oxygen.

Contact with a different kind of metal, either direct or indirect, can lead to corrosion of the more active one.

Corrosion of steel can be inhibited by galvanizing, that is, by coating it with zinc, a more active metal whose dissolution leaves a negative charge on the metal which inhibits the further dissolution of Fe2+.

Cathodic protection using an external voltage source is widely used to protect underground structures such as tanks, pipelines and piers. The source can be a sacrificial anode of zinc or aluminum, or a line-operated or photovoltaic power supply.